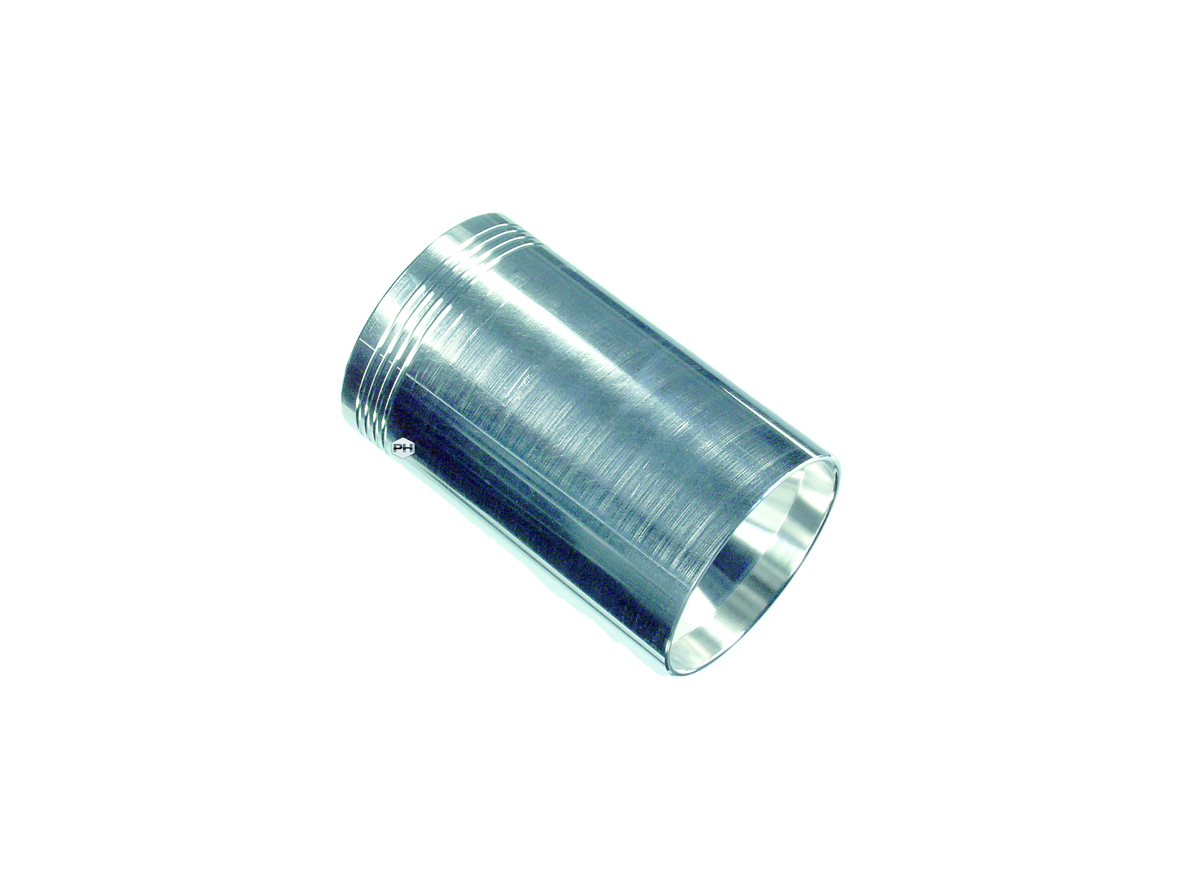

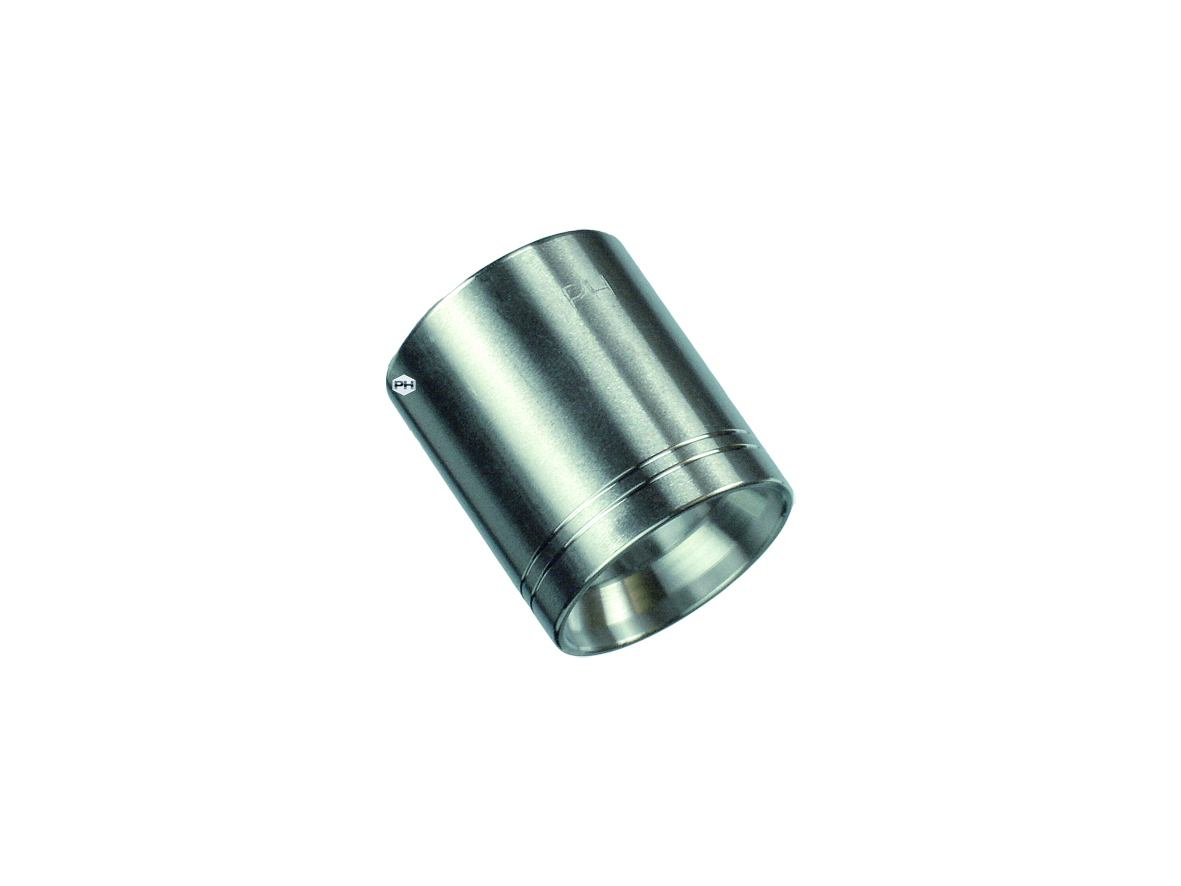

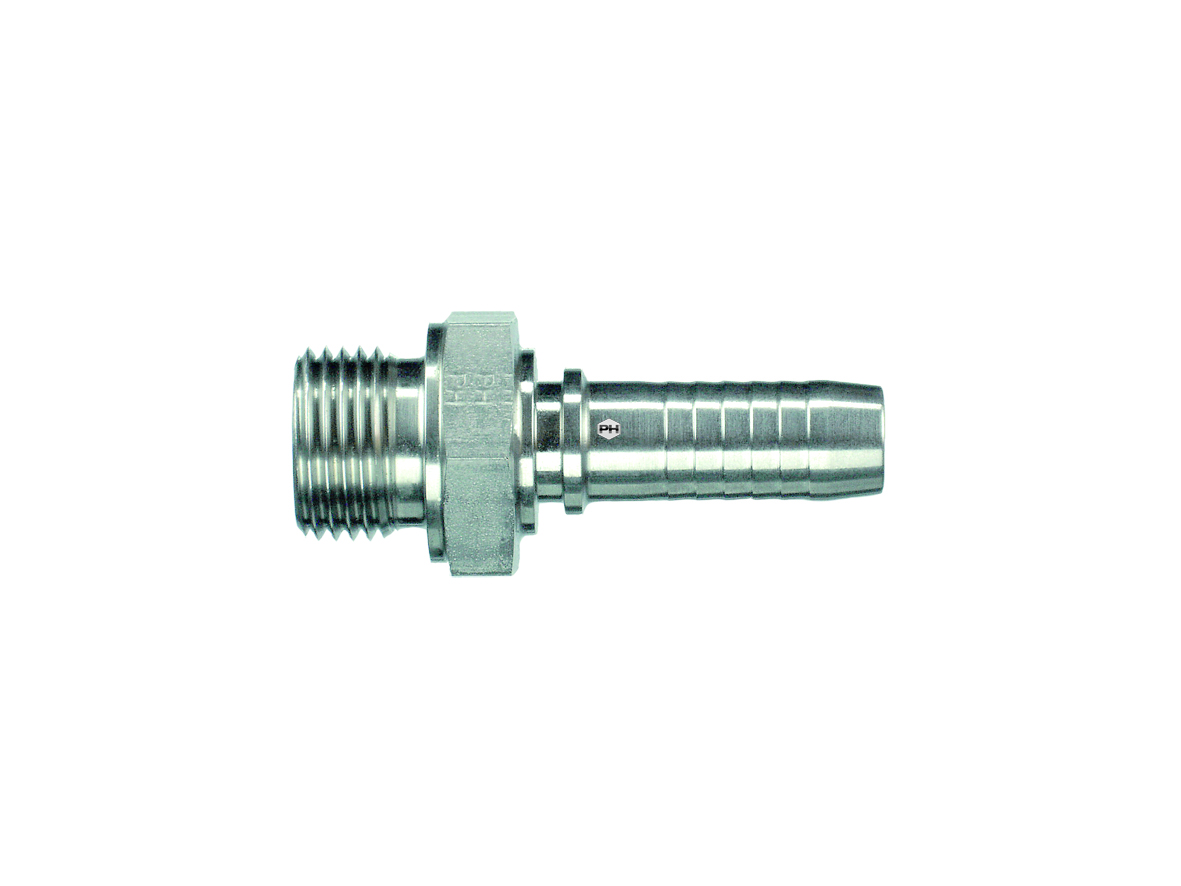

Hose Inserts & Ferrules

Stainless steel hose inserts and ferrules are essential components in high-pressure hose assemblies, providing secure and leak-free connections in hydraulic, pneumatic, and fluid transfer systems.

These components enhance the durability, reliability, and safety of hose connections in demanding environments.

Categories

-

Banjo Inserts

-

Capillary Banjos

-

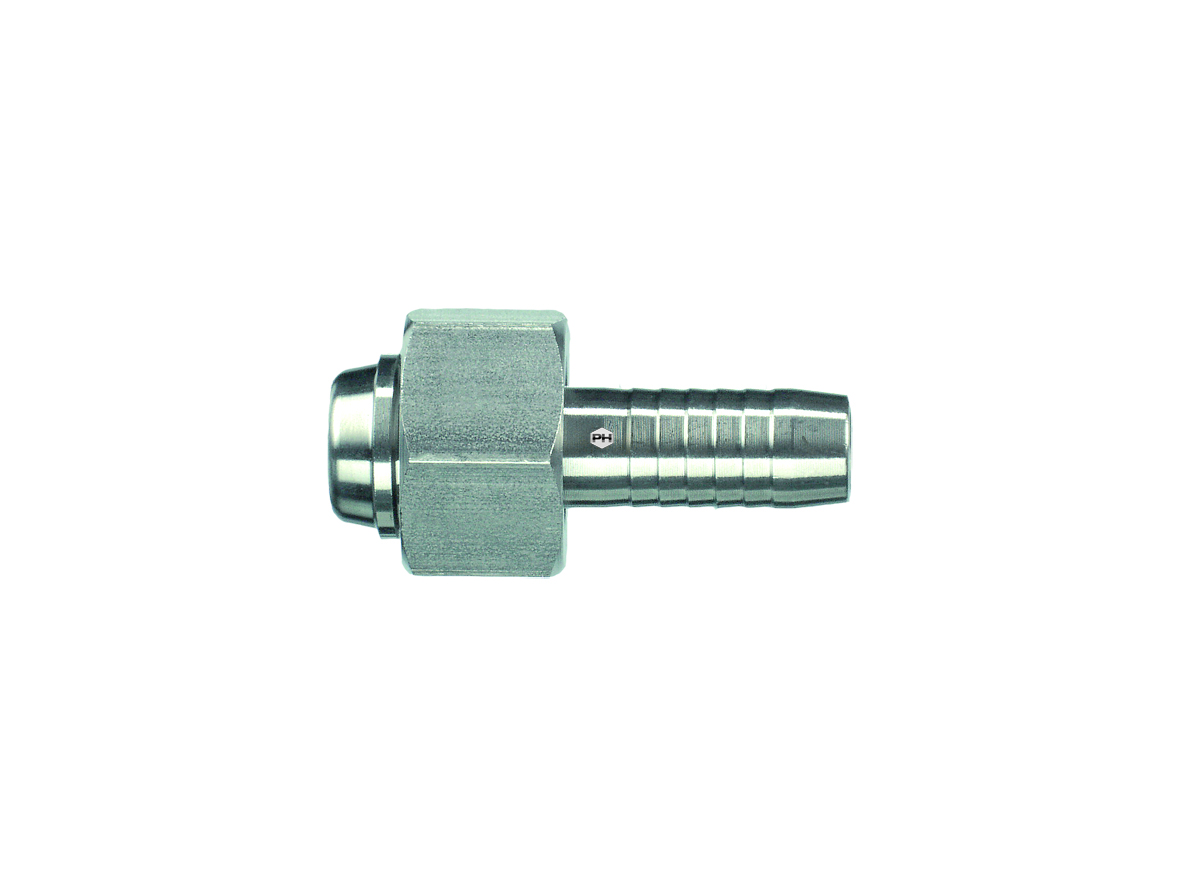

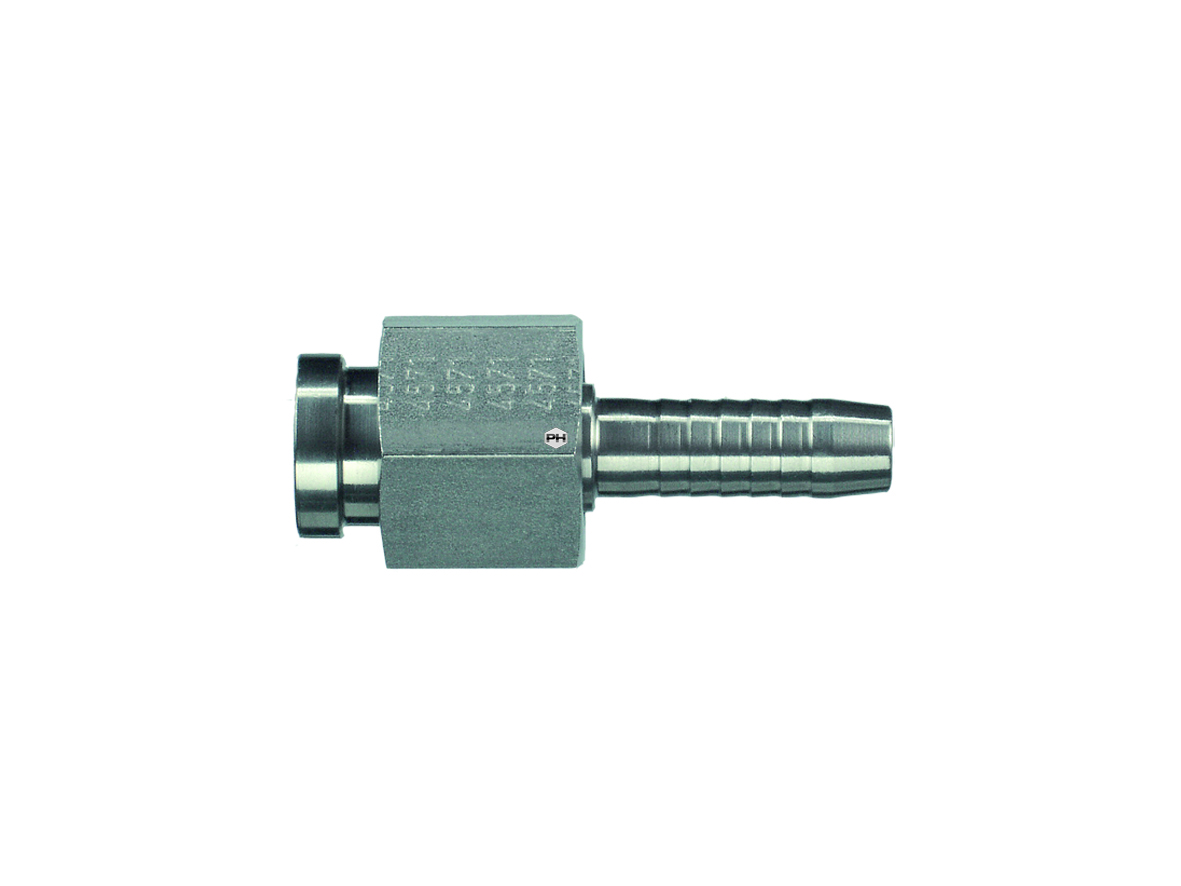

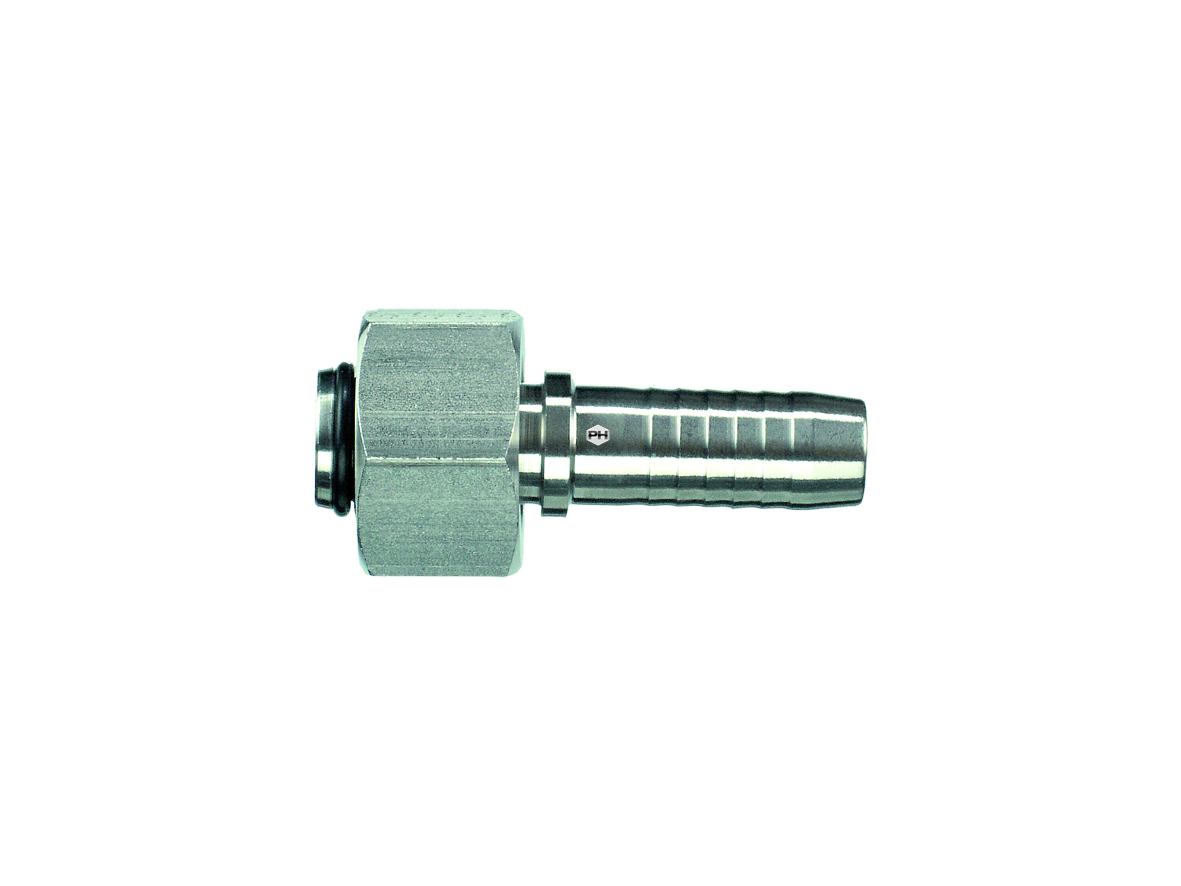

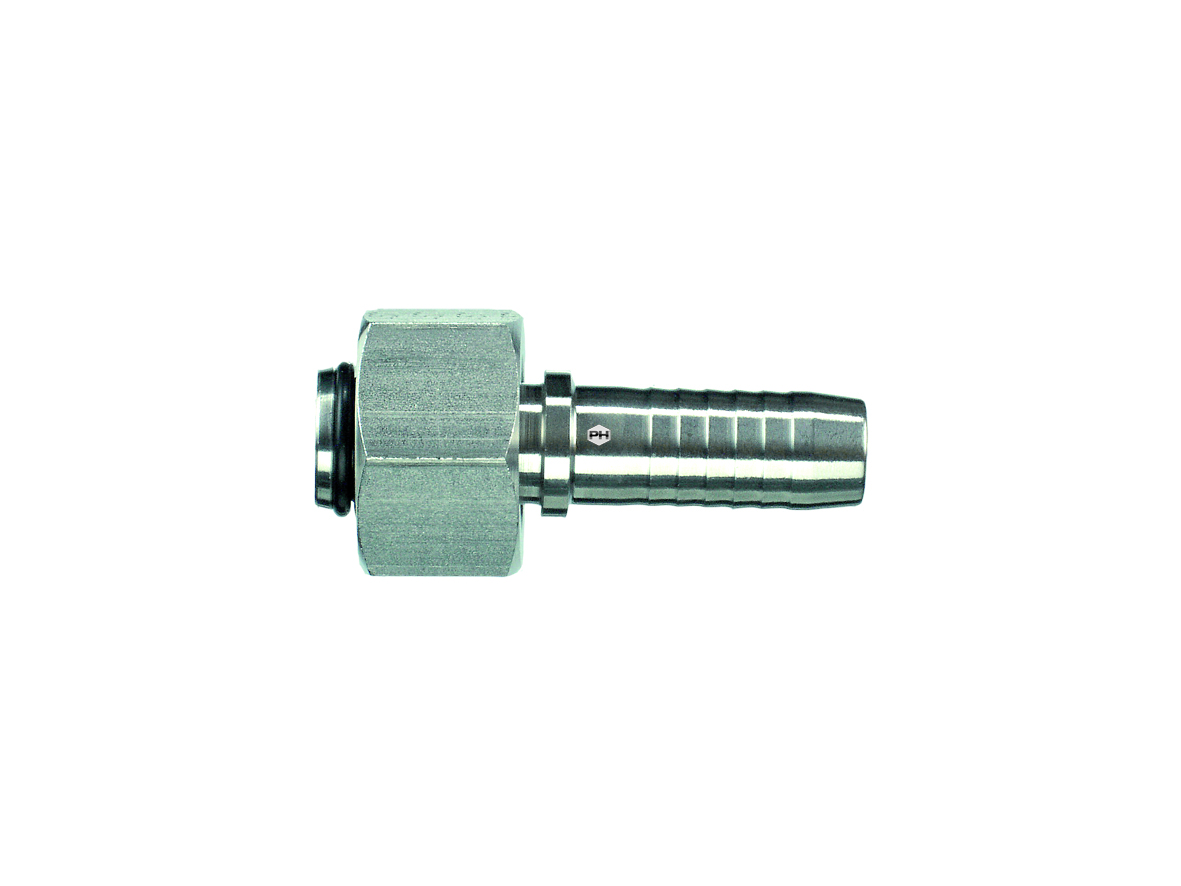

BSPP 60° Coned Female Push-on Hose Fitting

-

DIN Female Push-on Hose Fitting

-

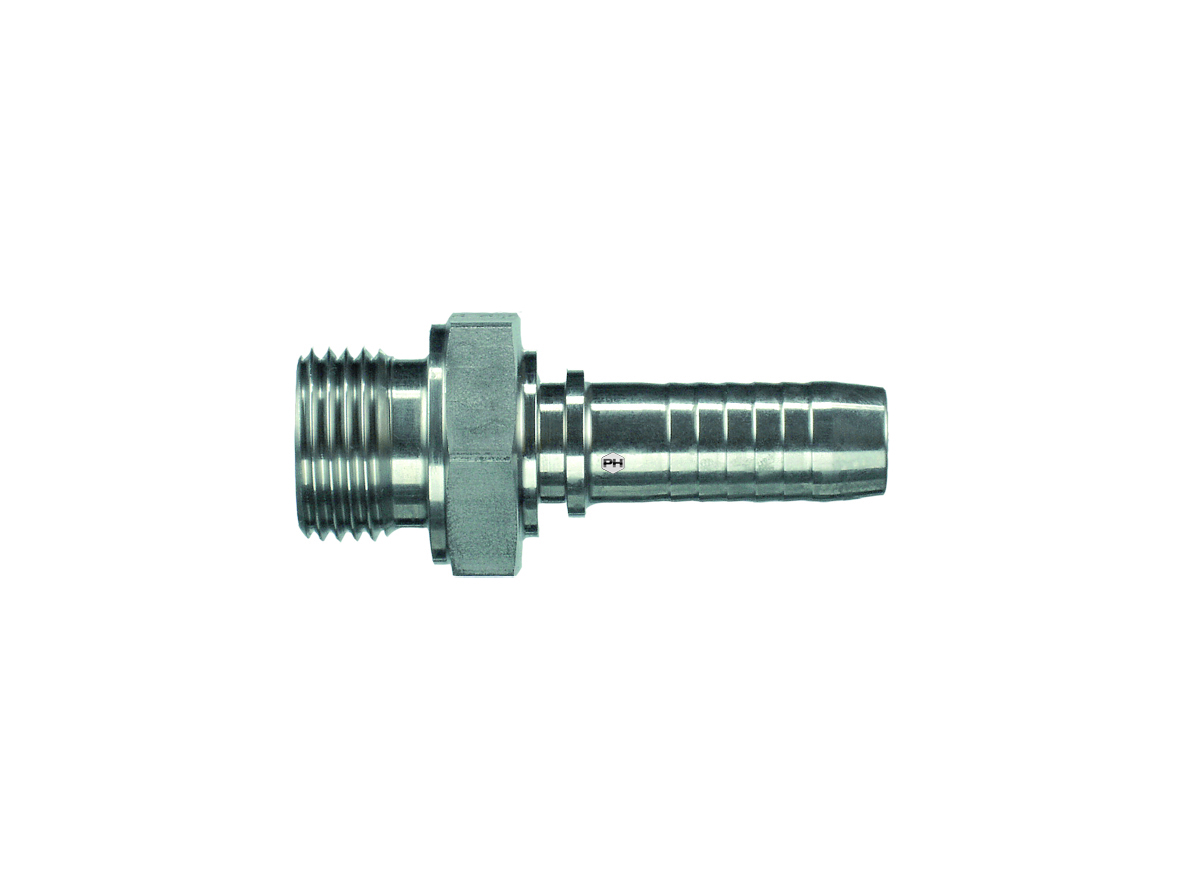

DIN Compression Male Push-on Hose Fitting

-

Standpipe Push-on Hose Fitting

-

BSPP Male Push-on Hose Fitting

-

Ferrules PF-W-PTFE

-

Ferrules PF-R7

-

Ferrules PF-PTFE

-

Ferrules P9

-

Ferrules P8

-

Ferrules P5

-

Interlock Ferrules P4

-

Ferrules P3

-

Ferrules P2

-

Ferrules P1

-

ORFS Male Inserts

-

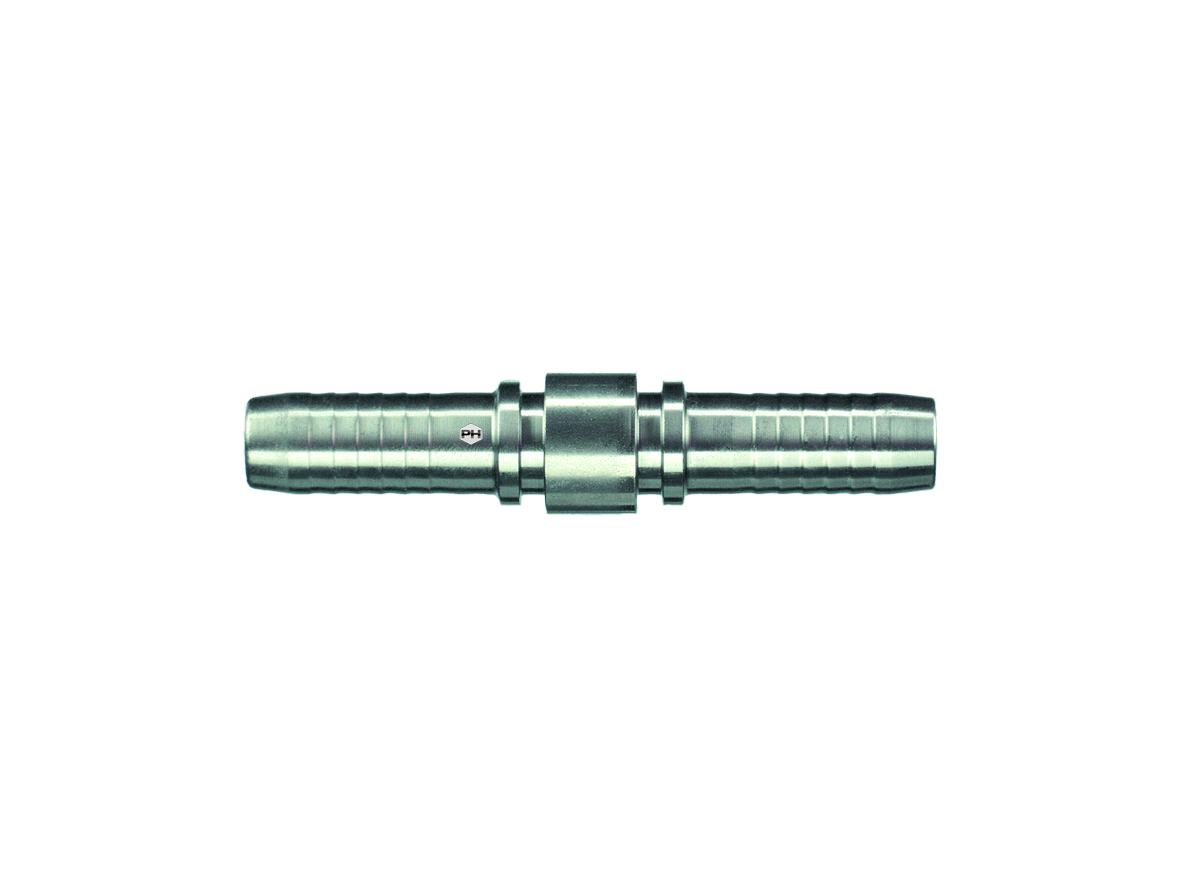

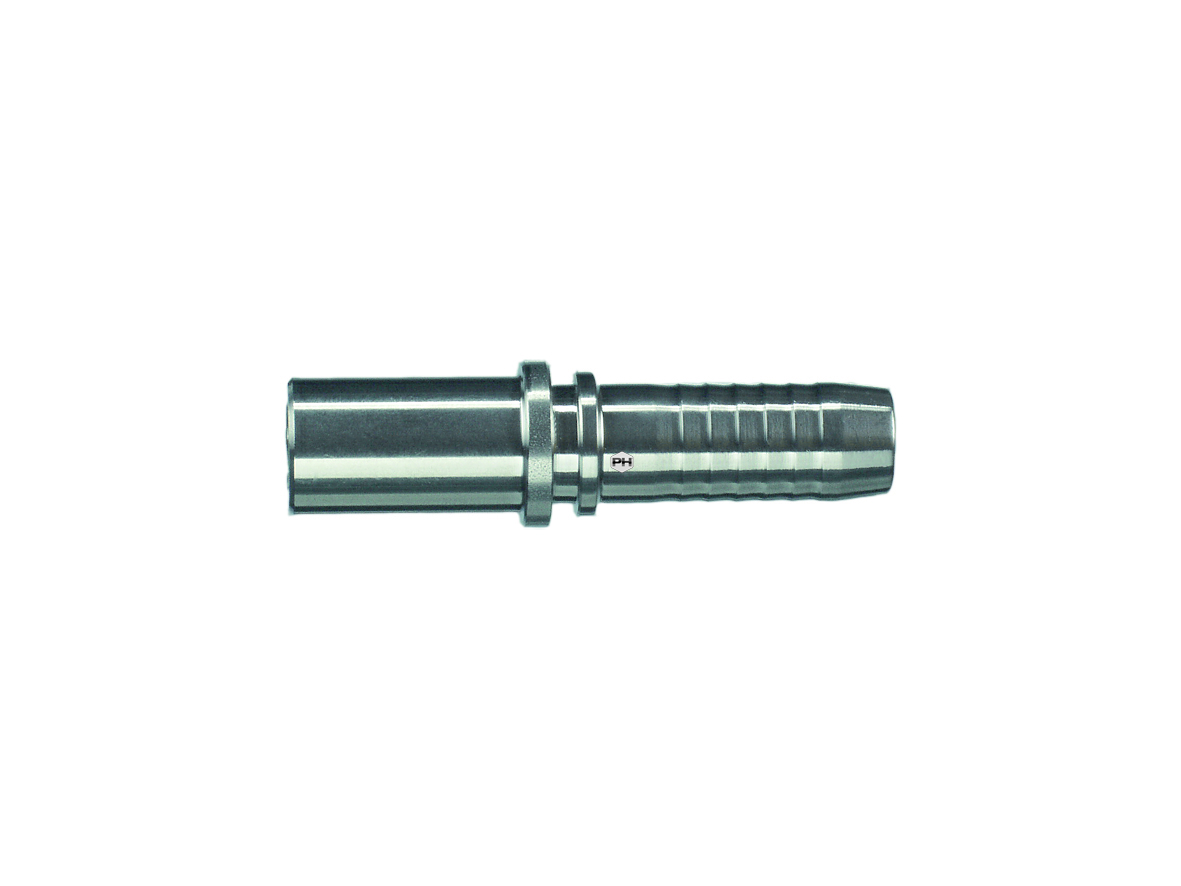

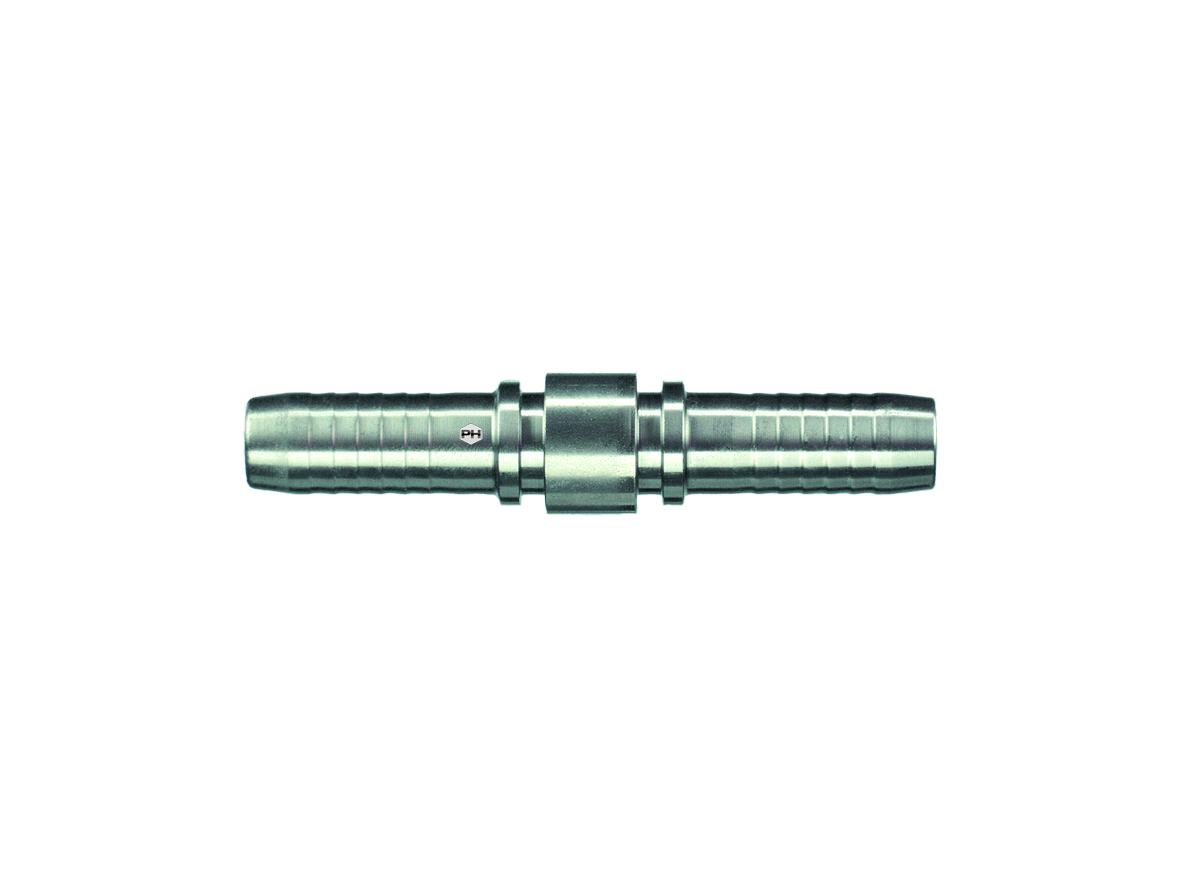

Hose Mender

-

BSP Flat-faced Inserts - 90°

-

BSP Flat-faced Inserts - Straight

-

BSP 60° Coned Female Inserts - 90°

-

BSP 60° Coned Female Inserts - 45°

-

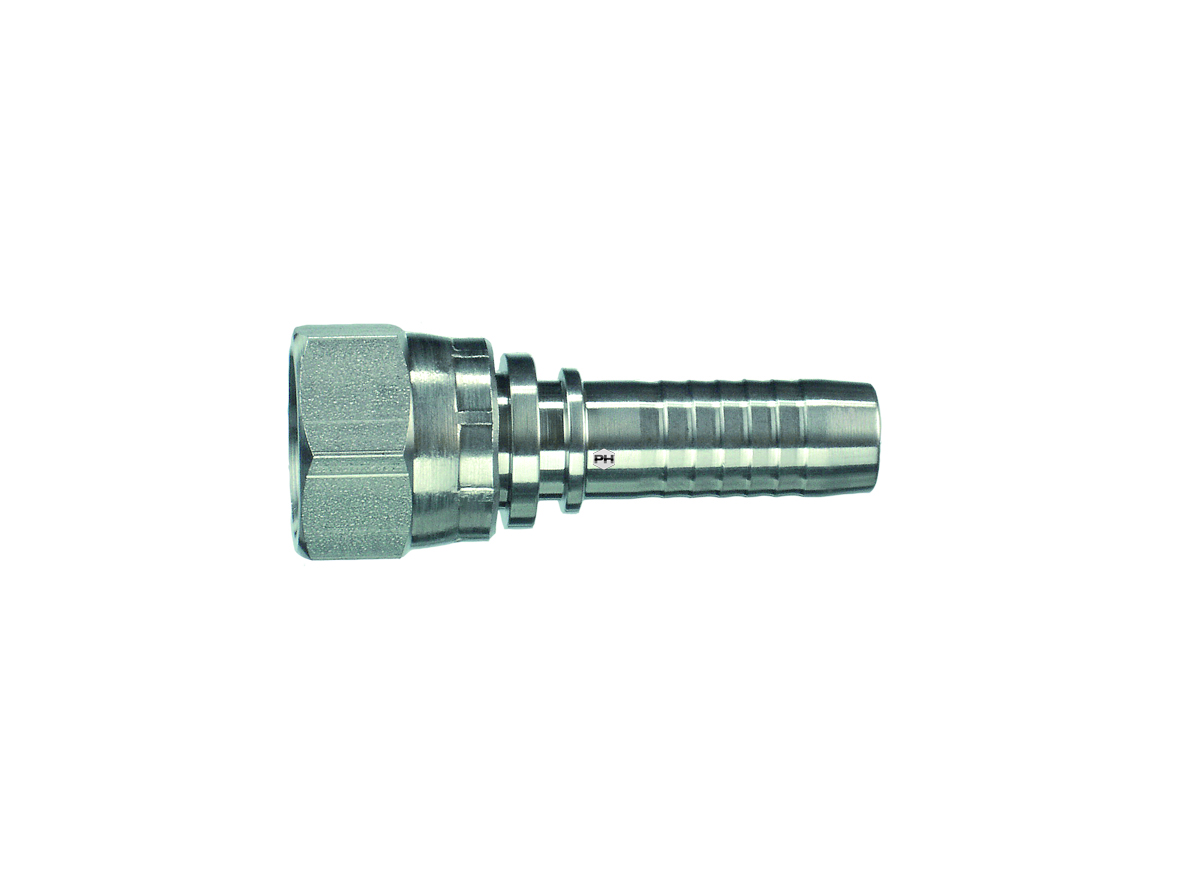

BSP 60° Coned Female Inserts - Straight

-

Universal Inserts - 90°

-

Universal Inserts - 45°

-

Universal Inserts - Straight

-

JIC 37° Female Inserts - 90°

-

JIC 37° Female Inserts - 45°

-

JIC 37° Female Inserts - Straight

-

DIN Compression 24° Male Inserts - Heavy Series

-

DIN Compression 24° Male Inserts - Light Series

-

Standpipe Connectors - Imperial Tube - Straight

-

Standpipe Connectors - Heavy Series - Straight

-

Standpipe Connectors - Light Series - 90° Elbow

-

Standpipe Connectors - Light Series - Straight

-

ORFS Inserts

-

ORFS Inserts

-

ORFS Female Inserts

-

SAE Split Flange Halves

-

SAE Split Flange Halves

-

Hose Mender

-

S series DIN Female 90 Elbow

-

S series DIN Female 45 Elbow

-

S series DIN Female Straight

-

L series DIN Female 90 Elbow

-

L series DIN Female 45 Elbow

-

L series DIN Female Straight

-

Waterwash Inserts

-

JIC - 37° - Female Nipples with Double Hexagon

-

Standpipe Connectors for Twin-Ferrule Fittings

-

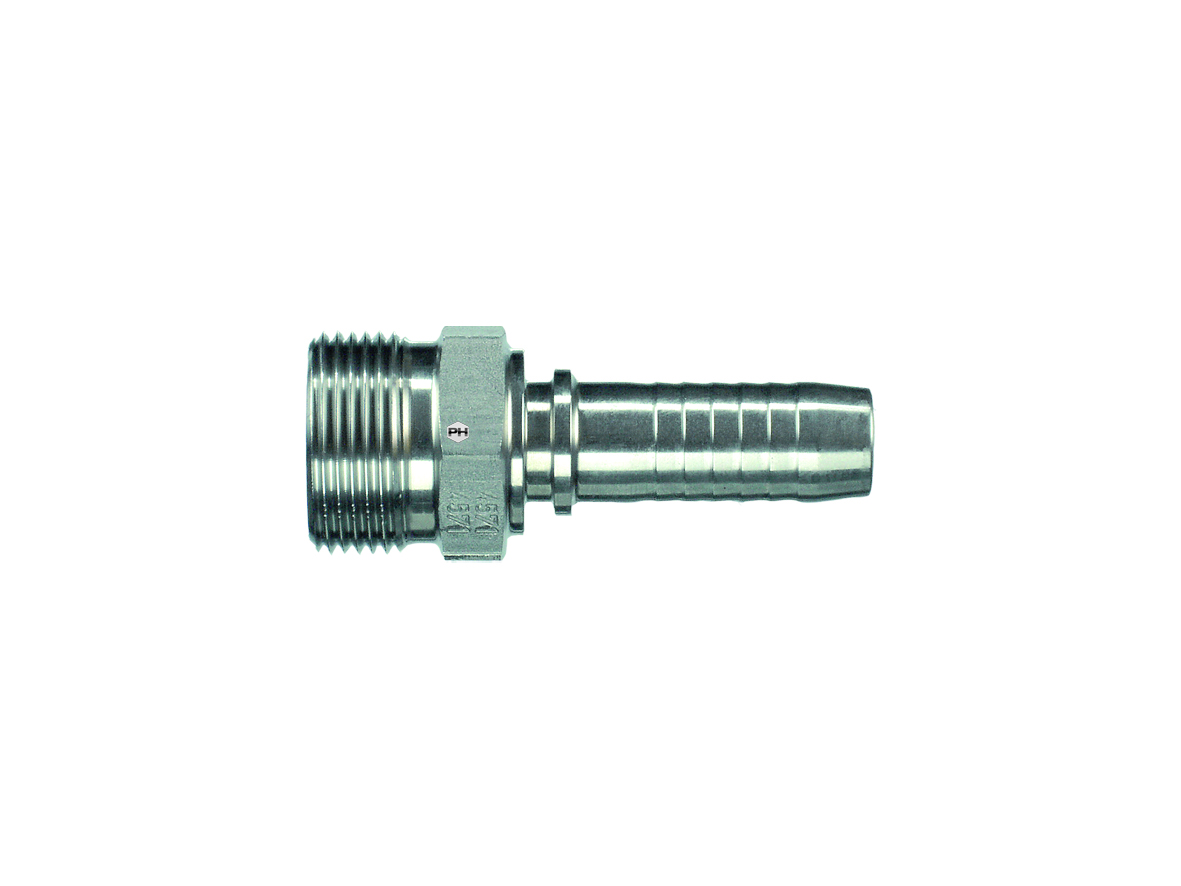

BSPP 60° Coned Male Insert

-

BSP Taper Male Inserts

-

NPT Male Inserts

-

JIC 37° Male Inserts

-

BSPP Flat-faced Male inserts

Key Components:

- Hose Inserts: Stainless steel fittings inserted into the hose end to create a secure connection with couplings or adapters. They often feature barbed, serrated, or threaded designs to ensure a leak-free connection.

- Ferrules: Cylindrical stainless steel sleeves that are crimped over the hose to reinforce the connection, preventing leaks, blow-offs, and damage from pressure fluctuations.

Key Features:

- Material: Typically 316 / 316L / 316Ti stainless steel, offering superior corrosion resistance, strength, and longevity.

- Compatibility: Designed for use with hydraulic, industrial, and food-grade hoses, ensuring a secure fit with various media, including oil, gas, water, and chemicals.

- Pressure & Temperature Resistance: Suitable for high-pressure applications and extreme temperatures, making them ideal for harsh environments.

Advantages:

- Prevents leaks and blow-offs, ensuring system reliability.

- High resistance to corrosion, chemicals, and extreme temperatures.

- Durable and long-lasting, reducing maintenance costs.

- Compatible with a wide range of hose types and applications.

Stainless steel hose inserts and ferrules are critical components in industries such as oil & gas, chemical processing, food & beverage, marine, and heavy machinery, ensuring safe, efficient, and durable hose connections.

Stainless steel hydraulic hose inserts and ferrules are essential for high-pressure, corrosion-resistant, and leak-proof hose connections. They are widely used in applications requiring durability, chemical resistance, and extreme pressure handling.

Choosing the correct stainless steel hydraulic hose ferrule is critical for ensuring a secure, leak-proof, and durable connection in high-pressure hydraulic and fluid transfer systems.

An improper selection can lead to hose failure, leaks, pressure loss, and system damage, resulting in costly downtime and potential safety hazards.

Hydraulic hose ferrules and inserts must be highly corrosion-resistant to withstand harsh environments, extreme pressures, and exposure to chemicals, moisture, and high temperatures.

Below are the most commonly used materials for ensuring durability and performance in corrosive applications:

1. Stainless Steel (316, 316L or 316Ti) – Most Common Choice

316 Stainless Steel (Marine Grade):

Superior corrosion resistance, especially in saltwater, chemicals, and extreme conditions.

Contains molybdenum (Mo), enhancing resistance to chlorides and acids.

Used in offshore, chemical, and food-grade applications.

2. Plated Carbon Steel (Zinc or Nickel Coated) – Cost-Effective Option

Carbon steel with zinc or nickel plating improves corrosion resistance.

Less expensive than stainless steel but prone to corrosion if plating wears off.

Not suitable for highly corrosive environments like seawater or strong acids.

3. Brass – Moderate Corrosion Resistance

Naturally corrosion-resistant but weaker than stainless steel.

Used in low- to medium-pressure applications.

More common in pneumatic, water, and fuel systems than in high-pressure hydraulics.

4. Monel (Nickel-Copper Alloy) – Extreme Corrosion Resistance

High resistance to saltwater, acids, and harsh chemicals.

More expensive than stainless steel but offers better performance in extreme environments.

Used in marine, offshore drilling, and chemical industries.

5. Titanium – High-End Corrosion Resistance & Lightweight

Exceptional strength-to-weight ratio with extreme corrosion resistance.

Immune to chlorine, seawater, and acidic environments.

Expensive but used in critical aerospace, medical, and deep-sea applications.

We are pleased to make available a broad range of hose insert fittings and ferrules, including – but not limited to – banjos, bolts, hose menders, interlock ferrules, pipe connectors, push-lock inserts, and tapered nipples.

Download Catalogue

We’ll email you a PDF version of our catalogue featuring 556 pages of updated engineering reference data. If you want a physical copy, click here