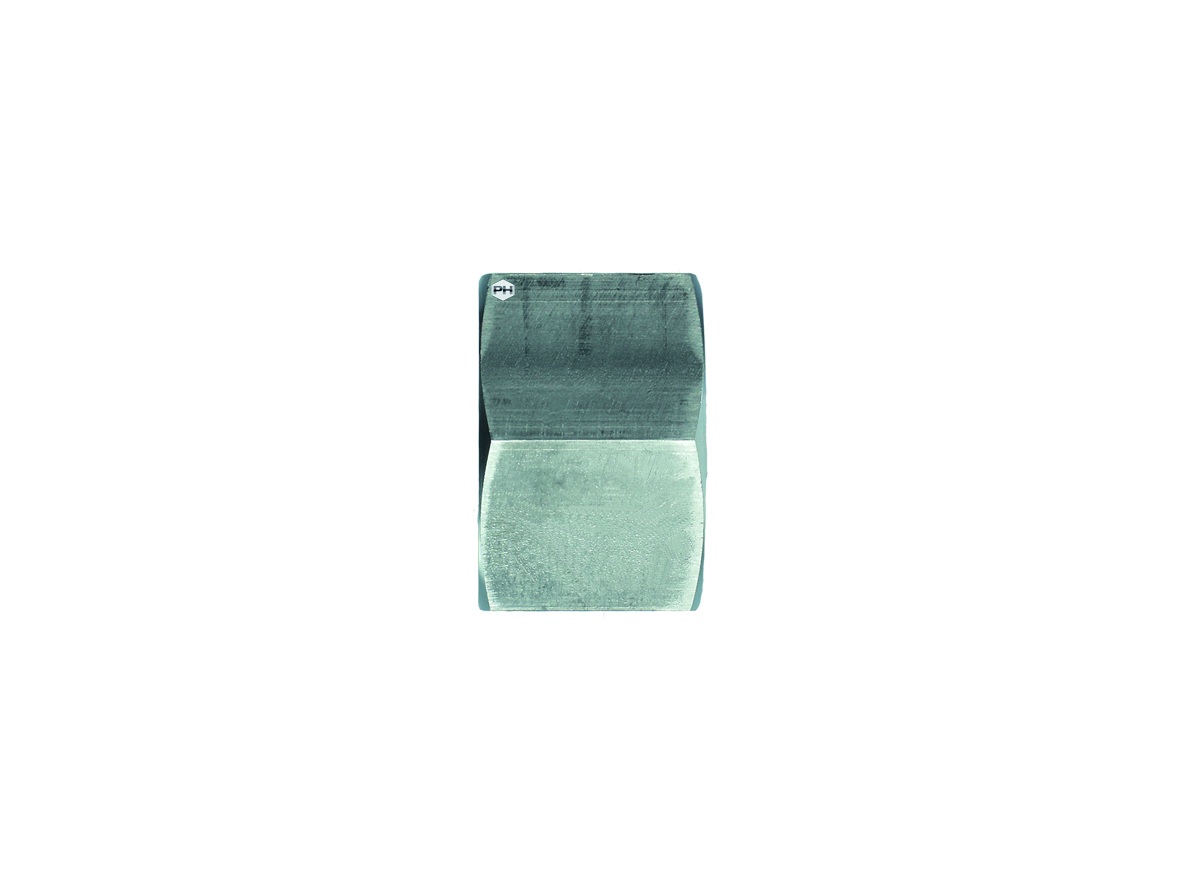

37° Flare Adapters for Compression Fittings

37° flare adapters are crucial components that bridge the gap between 37° flare connections and compression fitting systems. These adapters enable the connection of tubes in hydraulic systems using the reliable 37° flare seal while integrating with the versatility of compression fittings. Common applications include fluid transfer in manufacturing, hydraulic power units, and agricultural machinery.

Categories

Key Features

- Material: Stainless steel

- Connection Type: Combines a 37° flare connection on one end and a compression fitting connection on the other.

- Versatility: Allows for connecting tubes in a hydraulic system using a 37° flare seal with the adaptability of compression fittings.

- Standards Compliance: Compliant with industry standards, including ISO 8434-1 and DIN 2353 for hydraulic fluid power connections, ensuring interchangeability and reliable performance.

Advantages

Heat/Corrosion Resistance: These adapters offer excellent resistance to heat and corrosion.

Vibration-Resistant: The combination of a 37° flare seal and the compression fitting mechanism provides a robust connection that withstands vibration and mechanical shock.

Reusable: One of the key advantages of 37° flare adapters for compression fittings is their reusability. These adapters can be disassembled and reassembled multiple times, simplifying maintenance and reducing downtime.

Easy to Assemble: Compared to welding, both 37° flare adapters and compression fittings are relatively easy to assemble, reducing the installation time.

Suitability for High-Pressure Applications: When properly installed, 37° flare adapters can handle high-pressure hydraulic systems due to the metal-to-metal seal and compression fitting providing a secure grip on the tube.

FAQ's

Yes, 37° flare adapters and JIC fittings are designed to be compatible and are often used interchangeably.

37° flare adapters can be used with a variety of tube materials, including steel, stainless steel, copper, and aluminum. The compatibility depends on selecting the correct adapter material and ensuring the tube is properly sized and prepared.

Yes, 37° flare fittings are well-suited for high-pressure hydraulic systems. The metal-to-metal seal created by the 37° flare is designed to withstand significant pressure.

Yes, 37° Flare Adapters for Compression Fittings can generally be reused after disassembly. However, careful inspection of the sealing surfaces is crucial before reassembly. Any damage, such as scratches or dents, can compromise the seal and lead to leaks.

As well as a wrench, these adapters require the use of a flaring tool to properly form the 37° flare on the tube end before connecting it to the adapter. This tool ensures the correct flare angle and a smooth, even surface for a reliable seal.

Download Catalogue

We’ll email you a PDF version of our catalogue featuring 556 pages of updated engineering reference data. If you want a physical copy, click here