Compression Fittings With O-Ring Seals to DIN EN ISO 8434-1

Compression fittings with O-ring seals, compliant with DIN EN ISO 8434-1 standards offer reliable and leak-free connections for hydraulic systems.

-

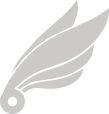

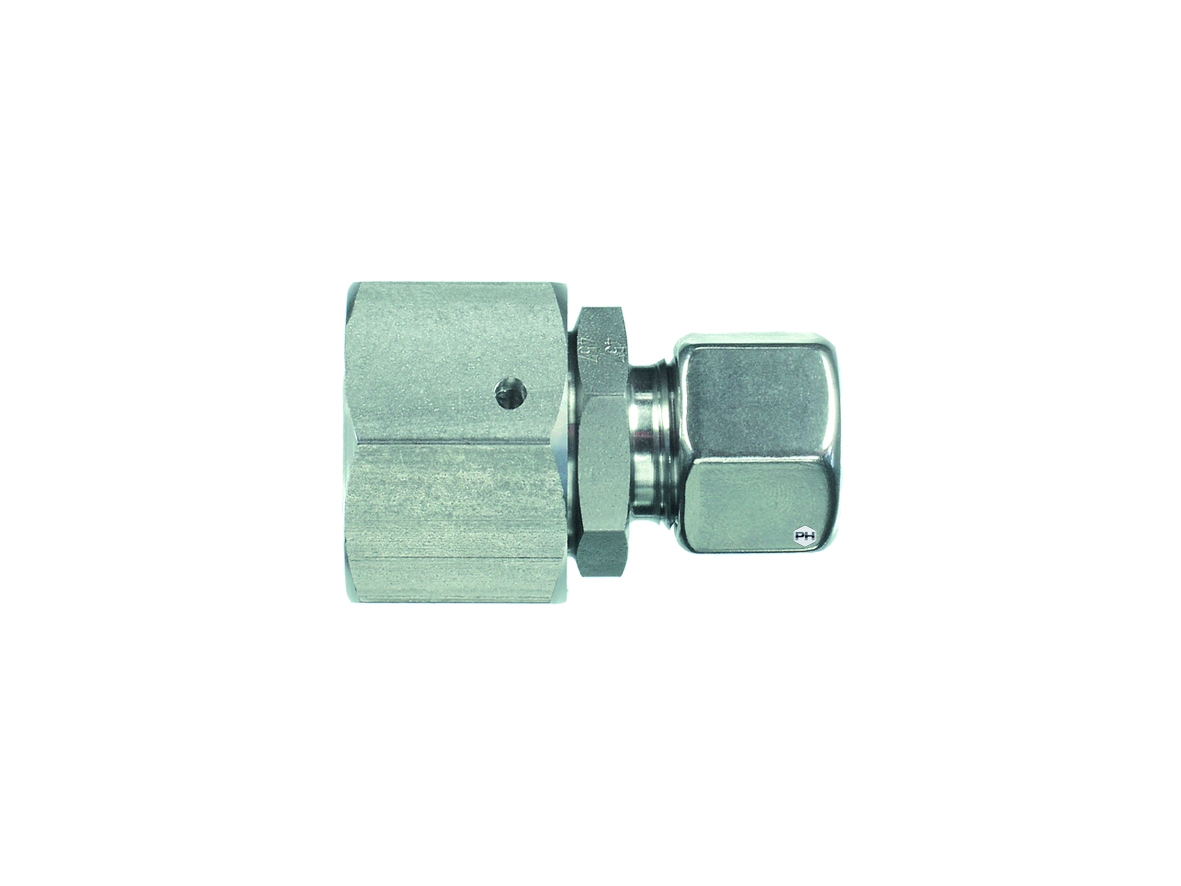

Straight female to male reducing coupling - body only

-

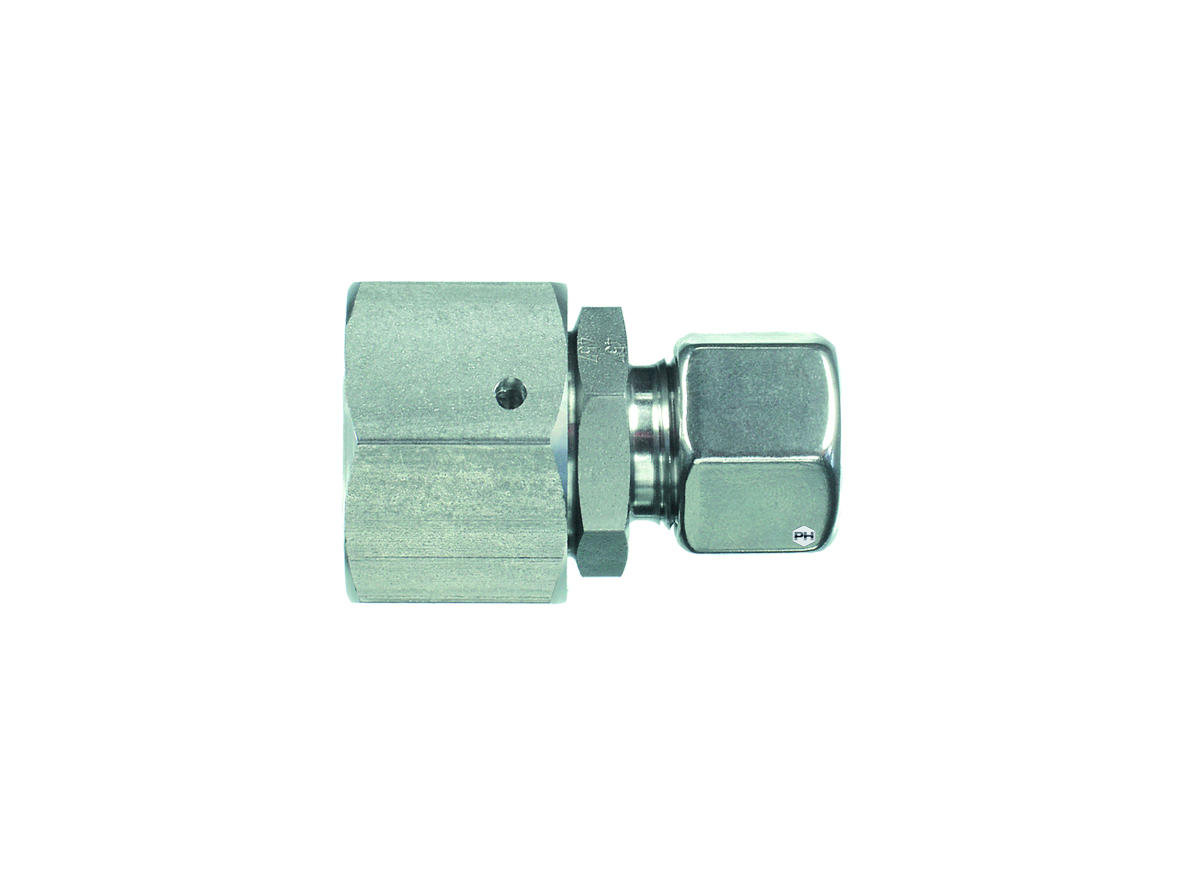

Straight female to male reducing coupling

-

Straight female to male reducing coupling - body only

-

Straight female to male reducing coupling

-

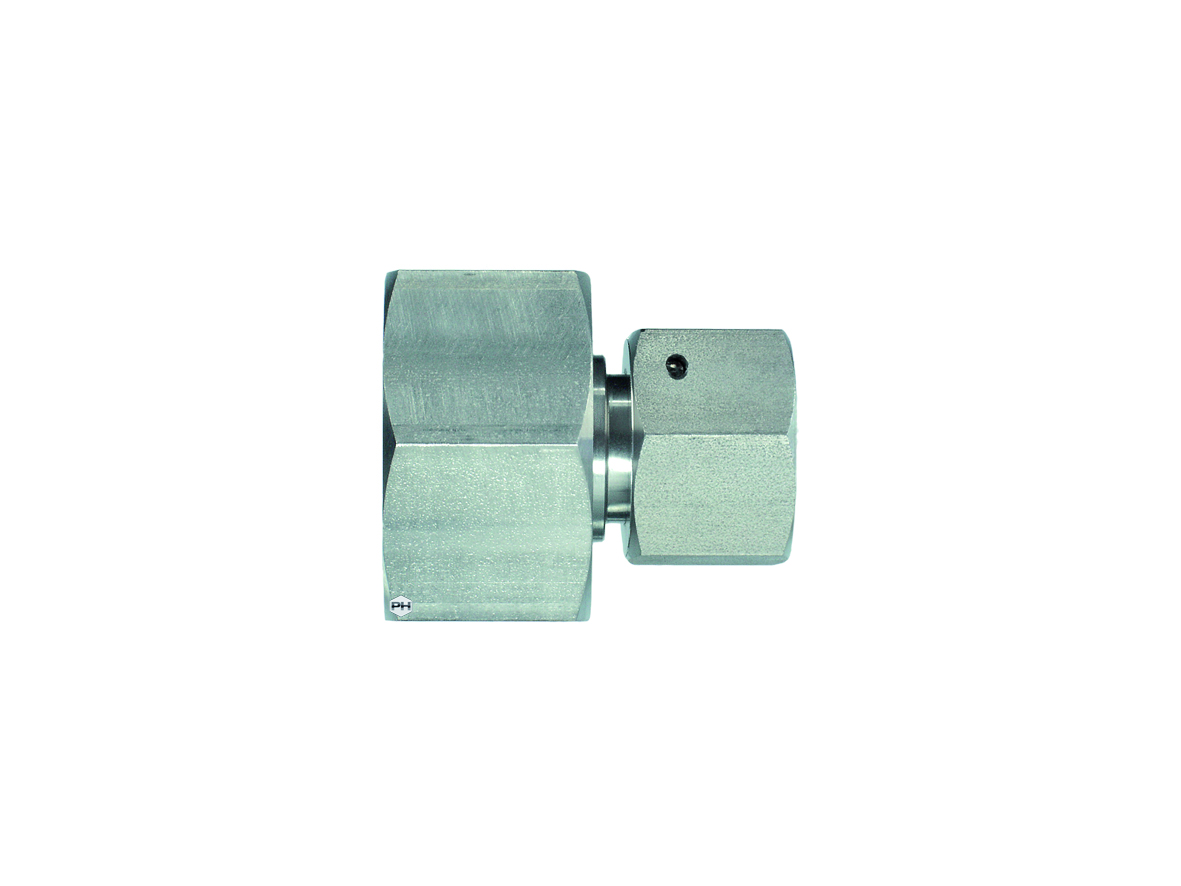

Swivel female to gauge female

-

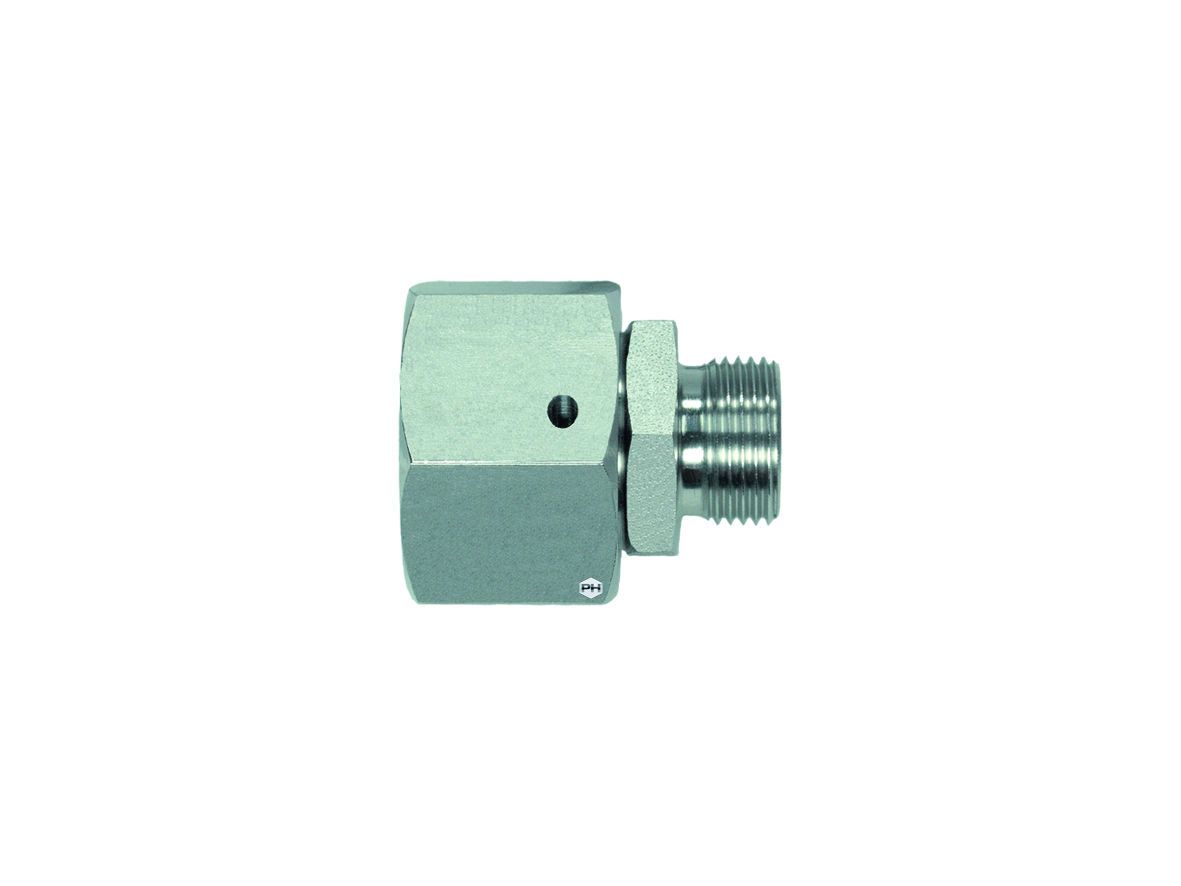

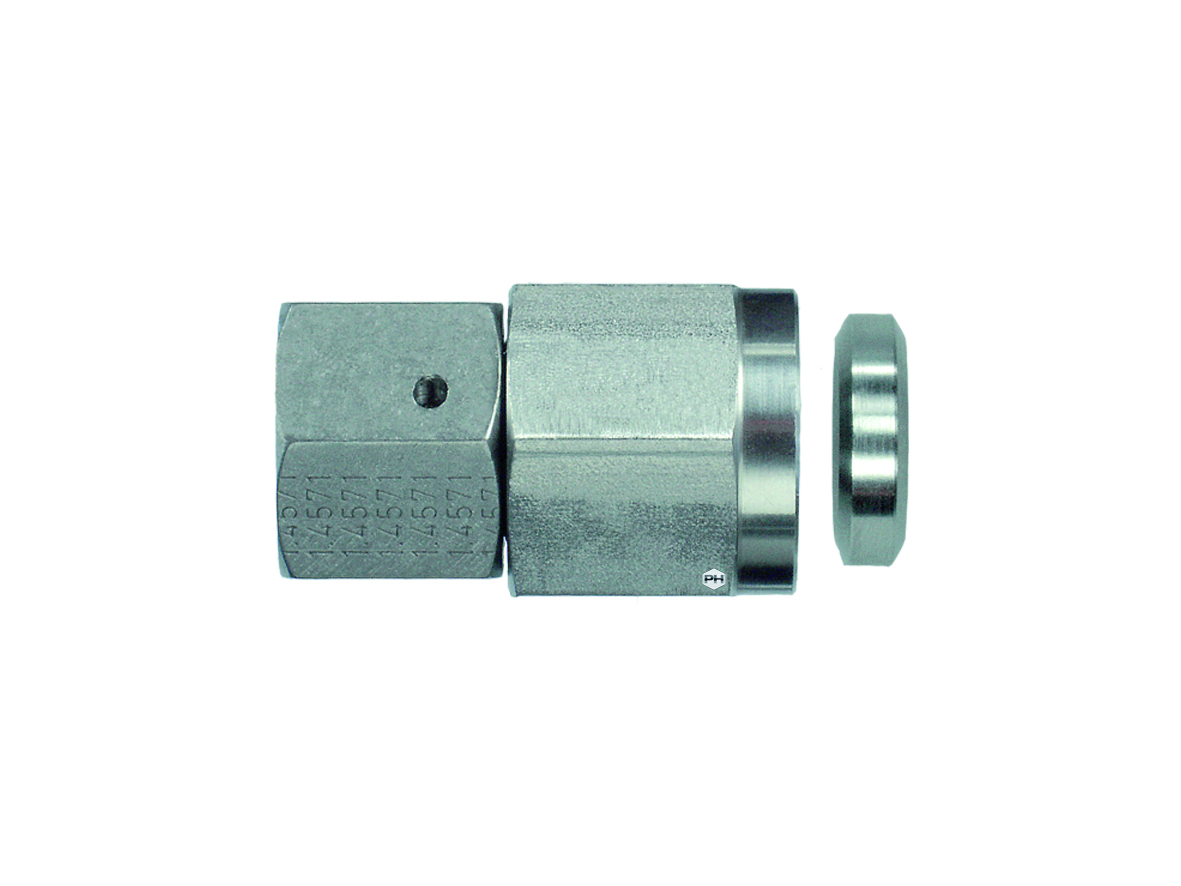

Straight female female reducing coupling (L to L & S to S series)

-

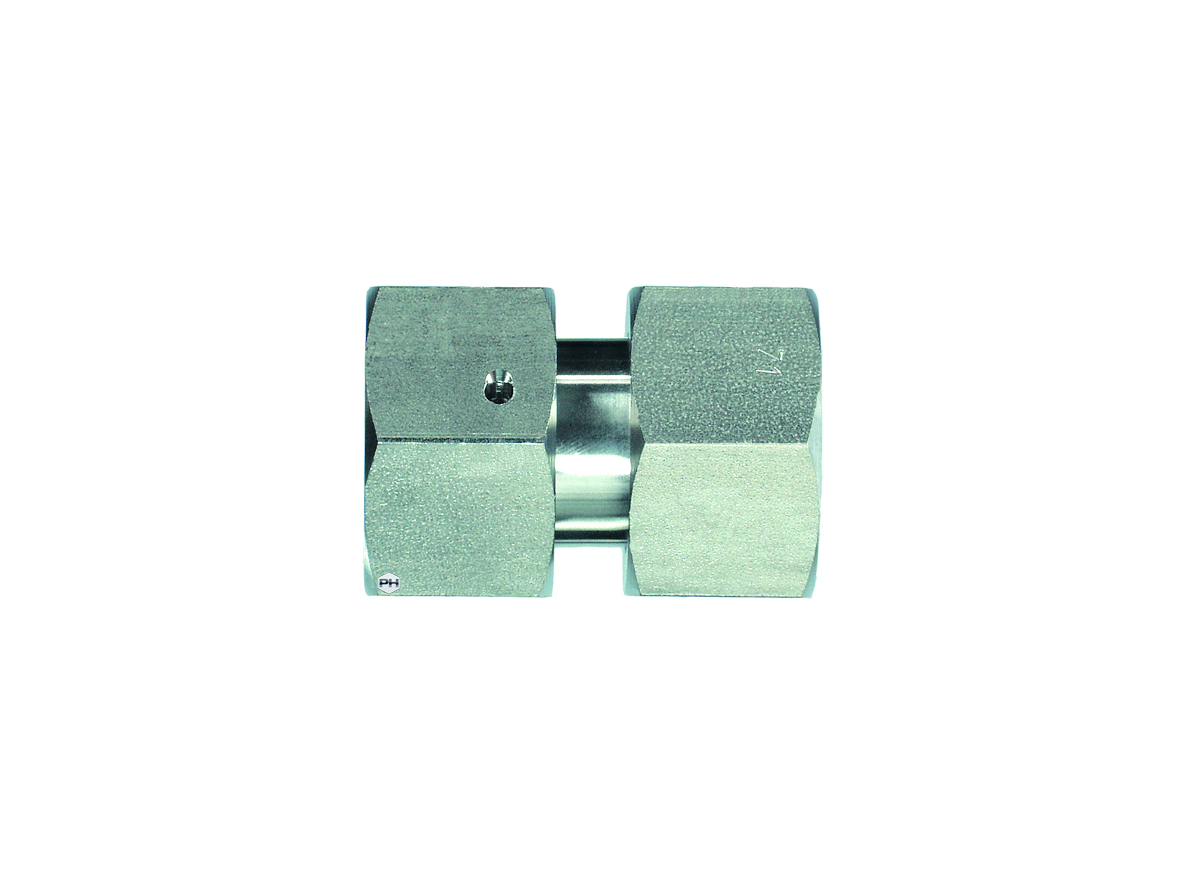

Straight female female coupling

-

Distance adapter - body only

-

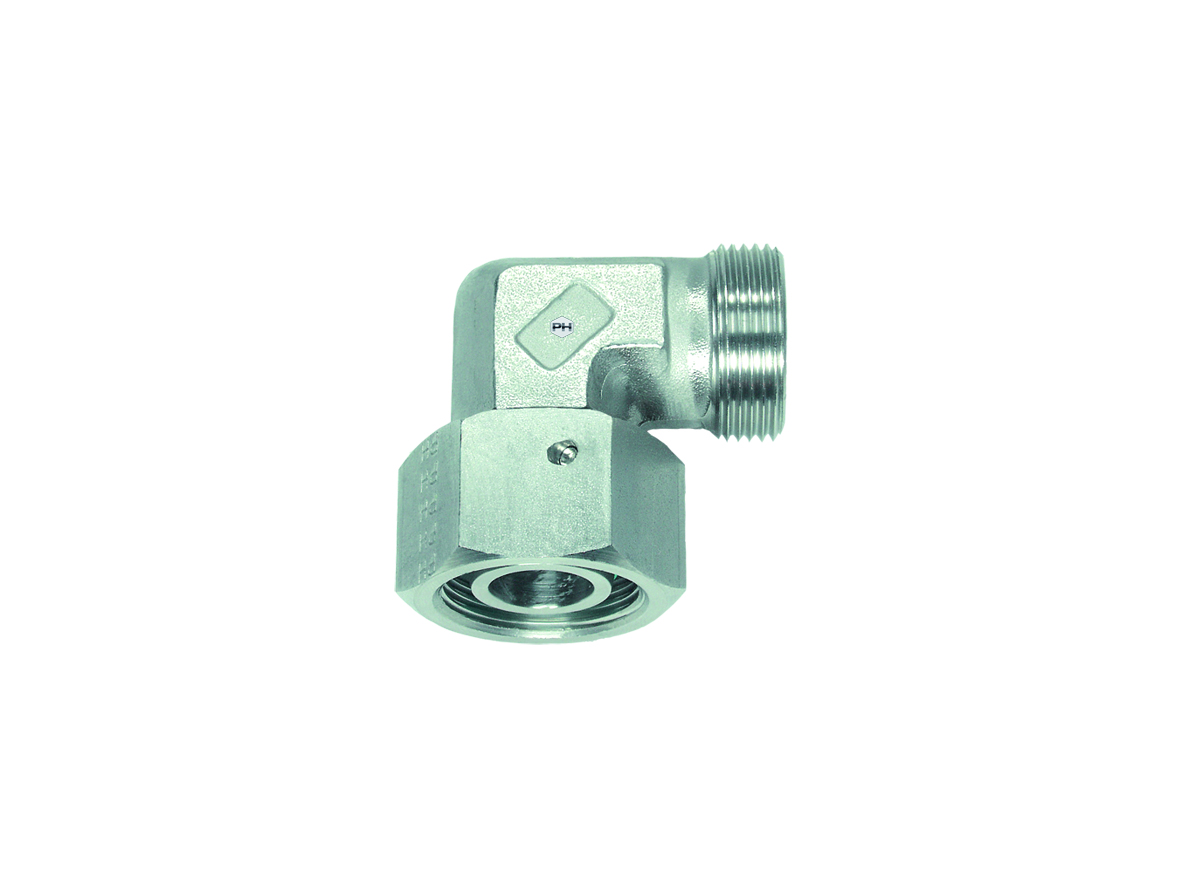

Adjustable female elbow - body only

-

Adjustable female elbow

-

Adjustable female 45° elbow - body only

-

Adjustable female 45° elbow

-

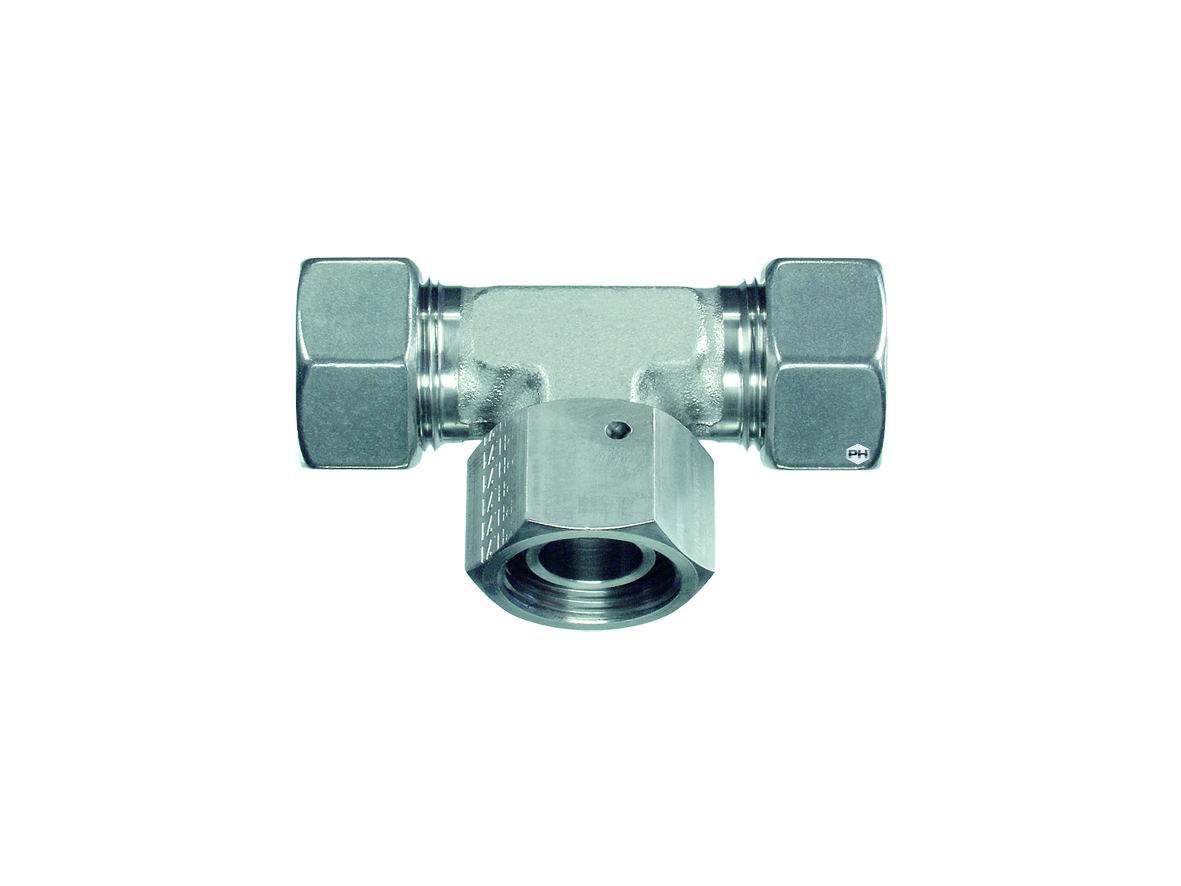

Adjustable female branch tee - body only

-

Adjustable female branch tee

-

Adjustable female run tee - body only

-

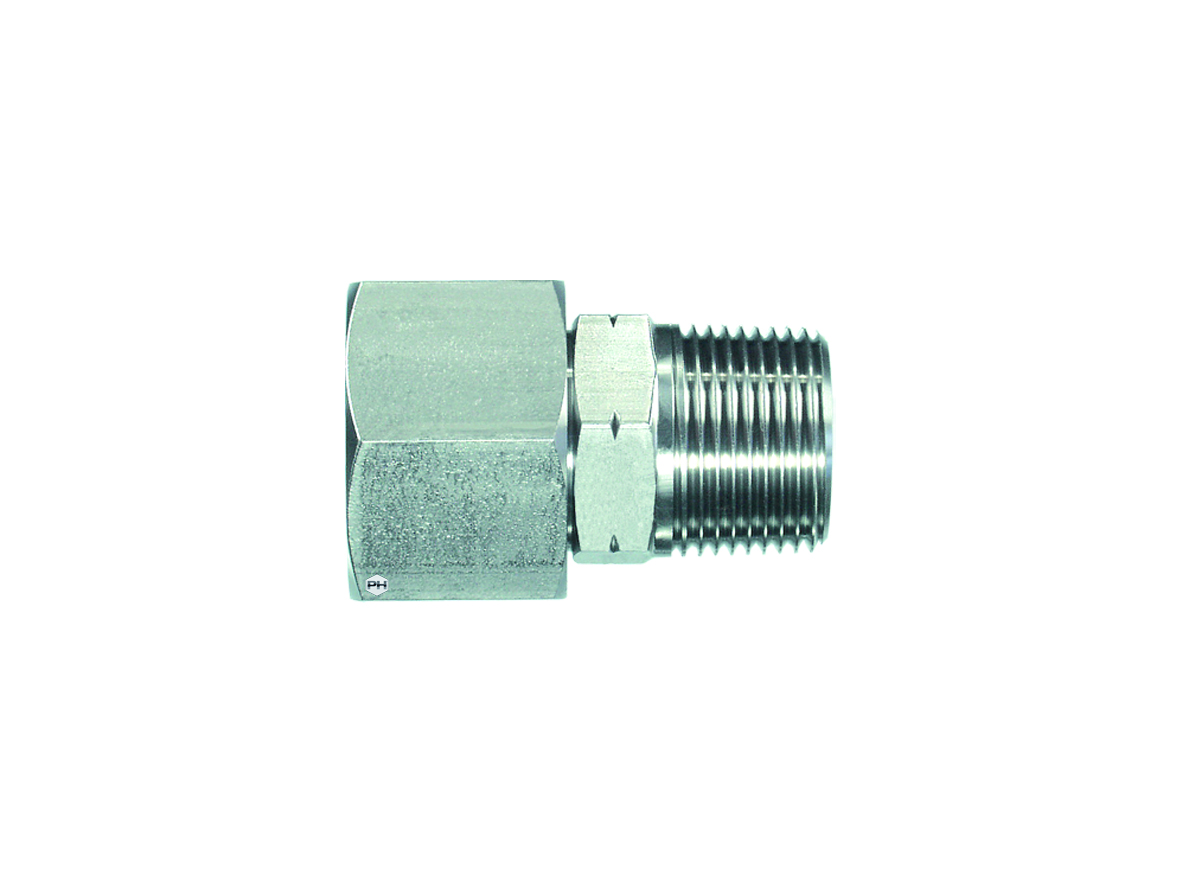

Swivel female to NPT male

-

Swivel female to BSP parallel male

Summary

The O-ring design ensures a superior seal, making them ideal for high-pressure applications and environments where vibration is a cause for concern. Common applications for this type of O-ring include hydraulic power units, heavy machinery, and fluid transfer systems across a range of industries such as manufacturing, agriculture, and construction.

Key Features

- Material: Stainless steel

- Seal Design: O-ring seal for enhanced leak prevention

- Pressure Ratings: Suitable for high-pressure applications

Advantages

The advantages of using Compression Fittings With O-Ring Seals To DIN EN ISO 8434-1 are that they offer:

Enhanced Leak-Tightness: The inclusion of an O-ring seal provides a superior level of sealing compared to standard compression fittings which is crucial in hydraulic applications where even minor leaks can lead to safety hazards and system inefficiencies.

Improved Reusability and Easier Maintenance: Unlike traditional cutting ring compression fittings, this type of O-ring seal often allows for easier disassembly and reconnection without damaging the tubing. This is particularly beneficial in systems requiring frequent maintenance, adjustments, or component replacements, as it reduces the need to cut and replace sections of tubing and the associated downtime.

Suitability for a Wider Range of Tube Materials: While standard DIN EN ISO 8434-1 compression fittings are primarily designed for steel tubes, the addition of an O-ring seal can make them more compatible with a broader range of materials. The O-ring provides a more forgiving sealing mechanism that can accommodate slight variations in tube surface finish and hardness compared to the direct metal-to-metal seal of a cutting ring.

FAQ's

O-ring compression fittings provide a more reliable and tighter seal, especially in high-pressure and vibration-prone environments.

Compression fittings can be used with some types of plastic tubing, but it depends on the plastic. Generally, softer, more flexible plastics like PVC or polyurethane are commonly not suitable unless reinforced.

Yes, Compression Fittings With O-Ring Seals To DIN EN ISO 8434-1 are suitable for harsh offshore and marine environments due to their corrosion resistance.

Yes, these compression fittings with O-ring seals comply with DIN EN ISO 8434-1 standards.

Download Catalogue

We’ll email you a PDF version of our catalogue featuring 556 pages of updated engineering reference data. If you want a physical copy, click here