Compression Fittings

Compression fittings are a type of coupling used to connect two tubes without the need for welding, flaring, or threading, making them practical solution to create a secure and leak-tight seal. These versatile fittings are widely used across various industries, including hydraulics, oil and gas, offshore, marine, chemical, paper manufacturing, for their ease of installation and reliability in both low and high-pressure applications.

At Pegasus Hydraulics, we offer a comprehensive selection of compression fittings, including those designed to ISO 8434-1 / DIN 2353 standards, as well as options with O-ring seals for enhanced performance, and weld fittings for permanent connections.

-

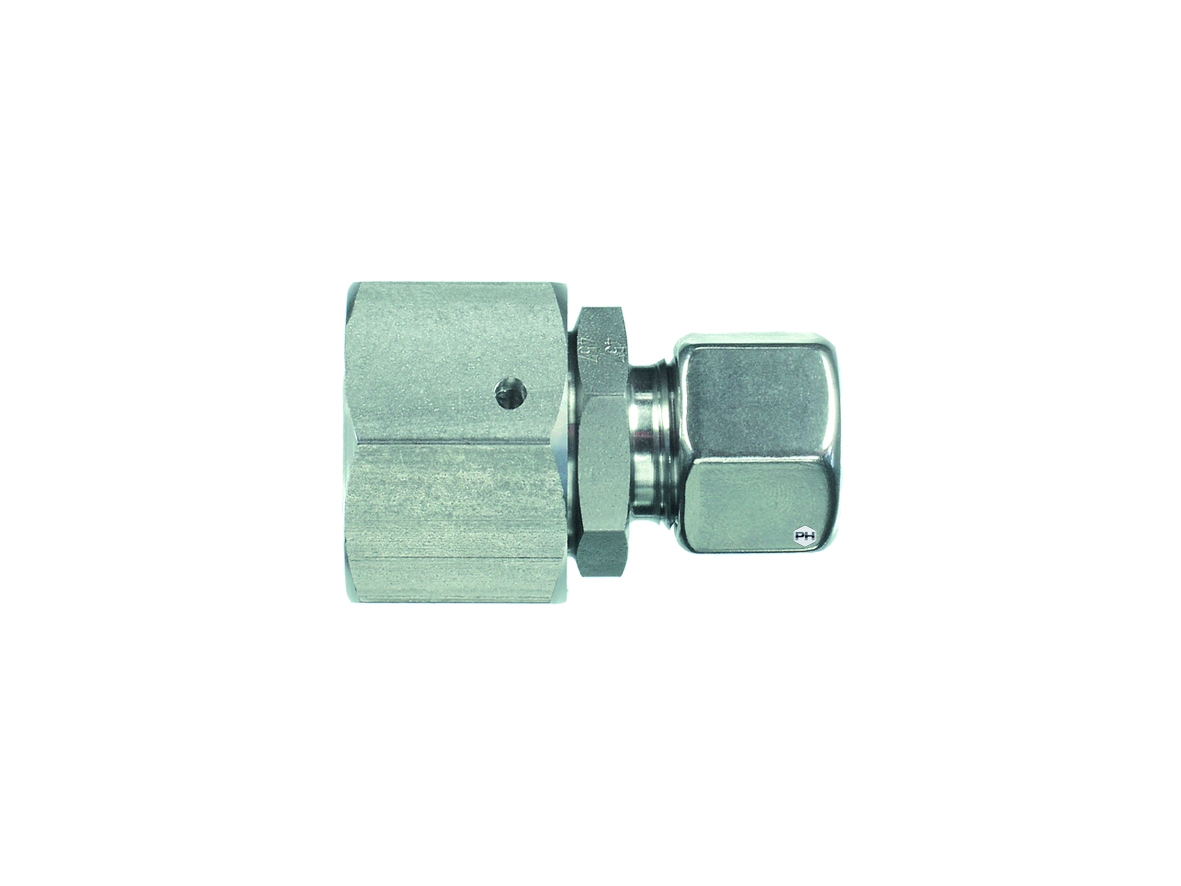

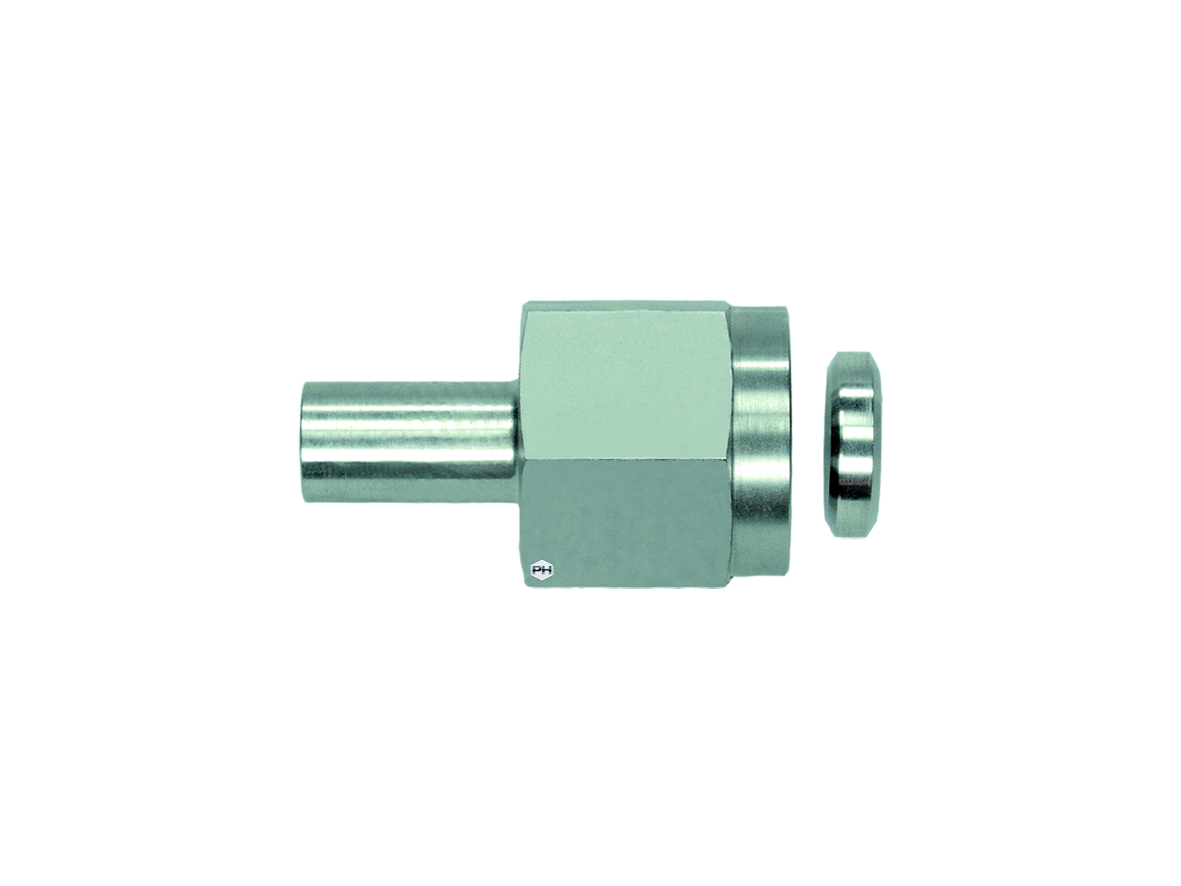

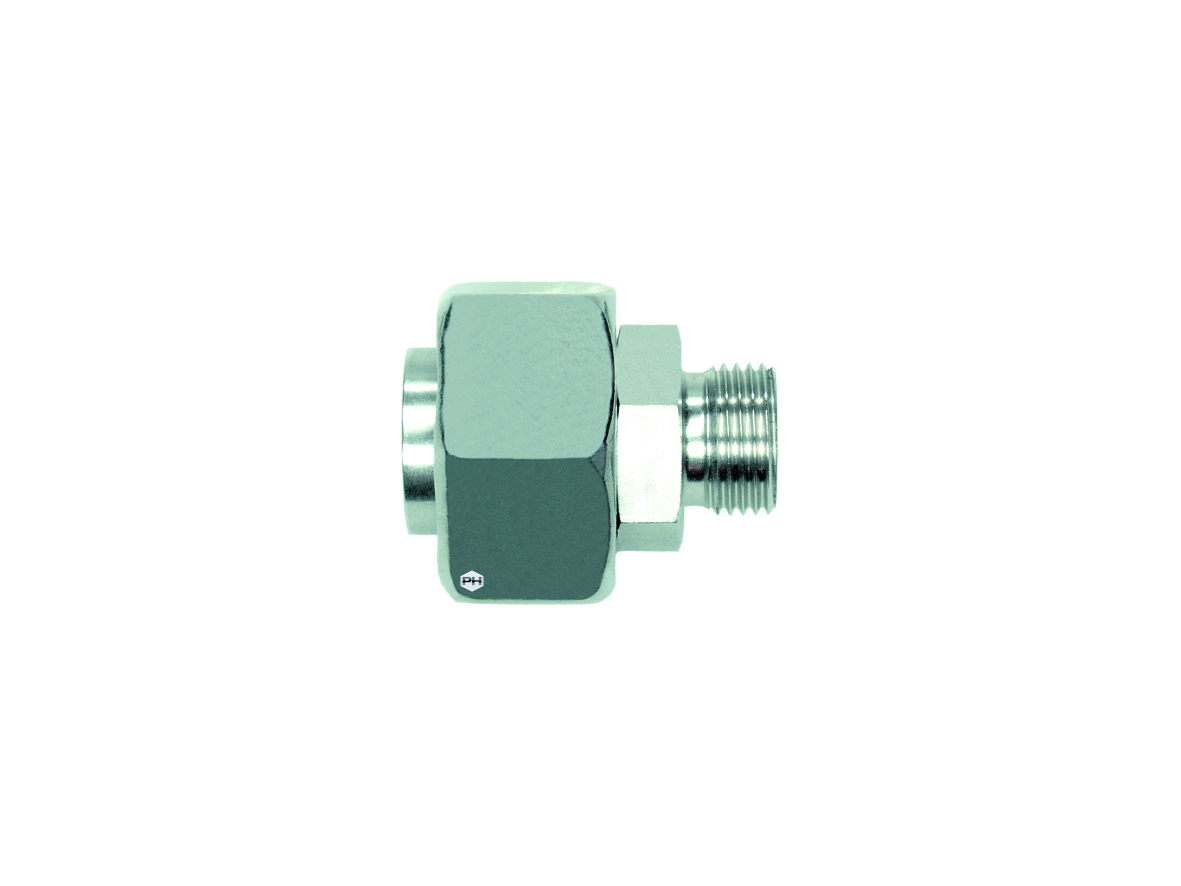

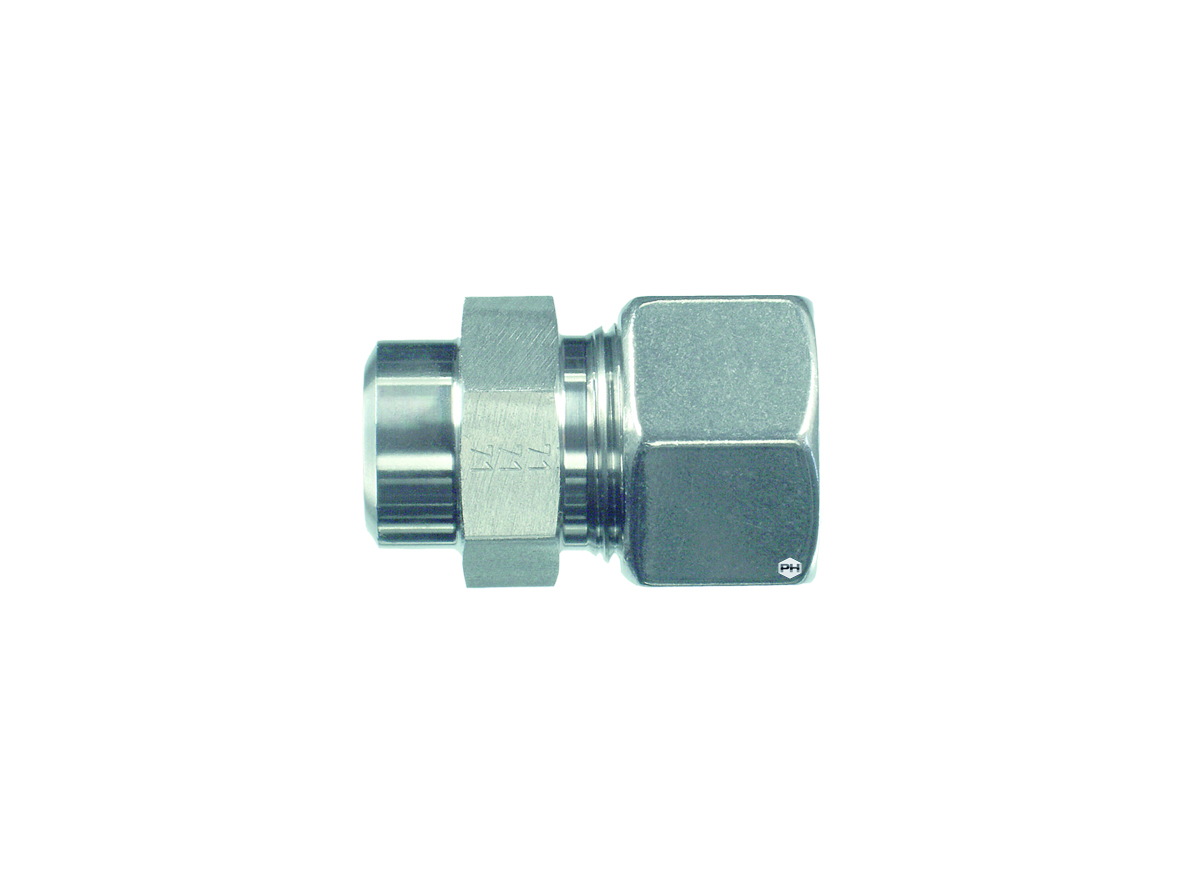

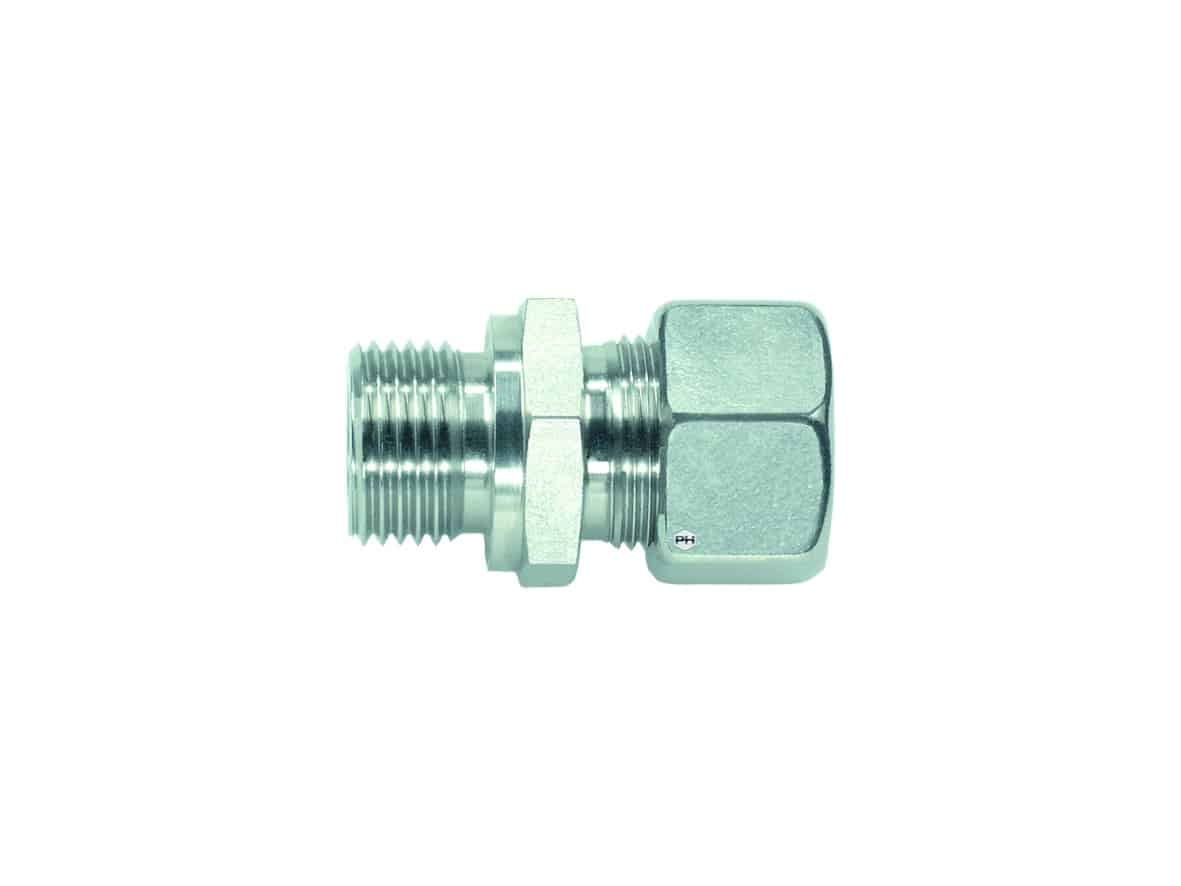

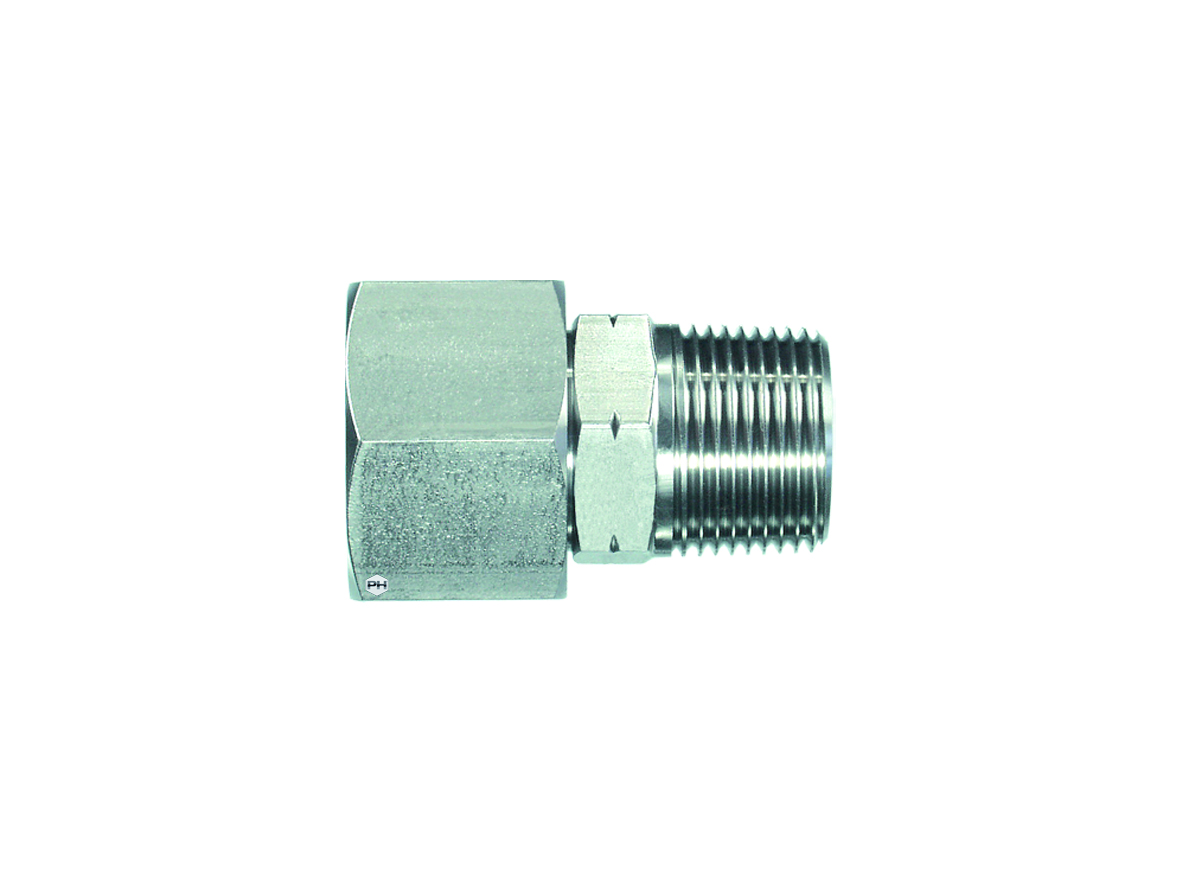

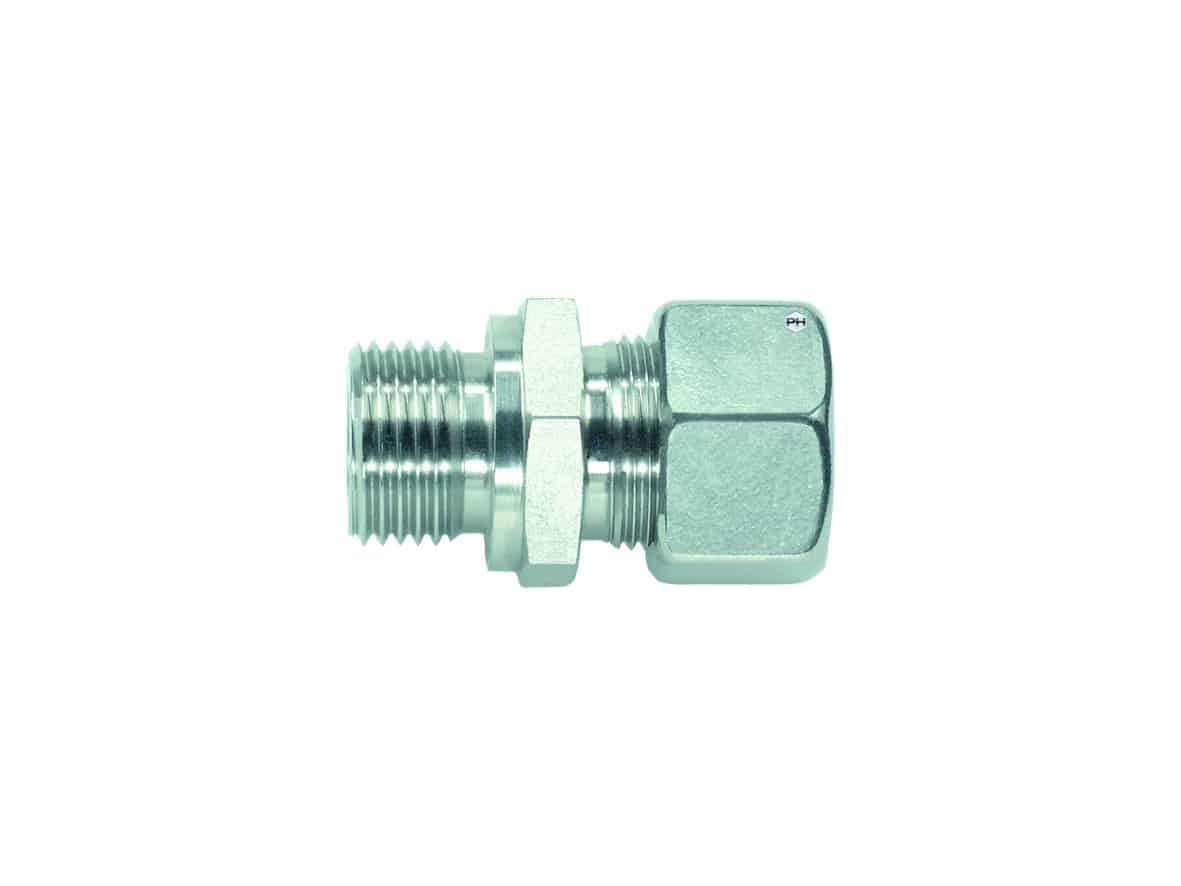

Straight female to male reducing coupling - body only

-

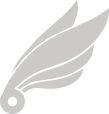

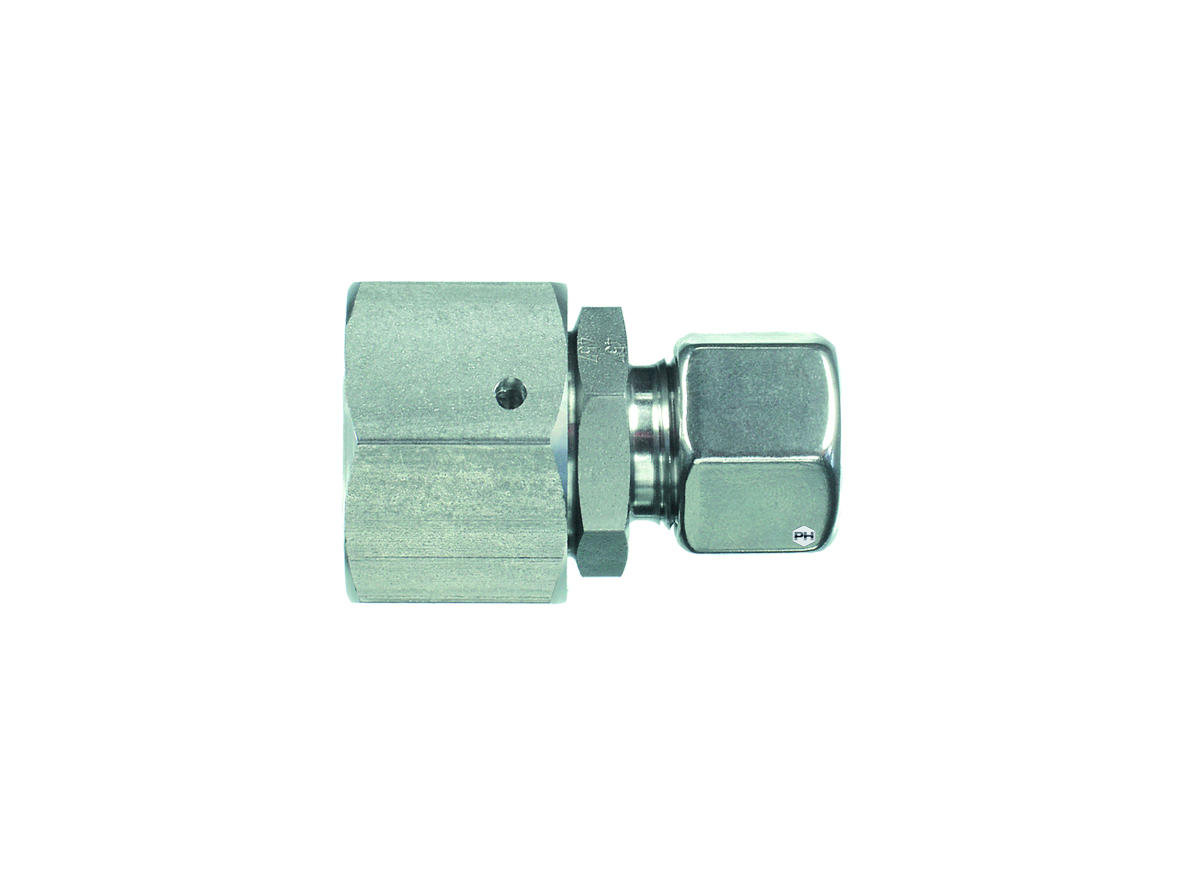

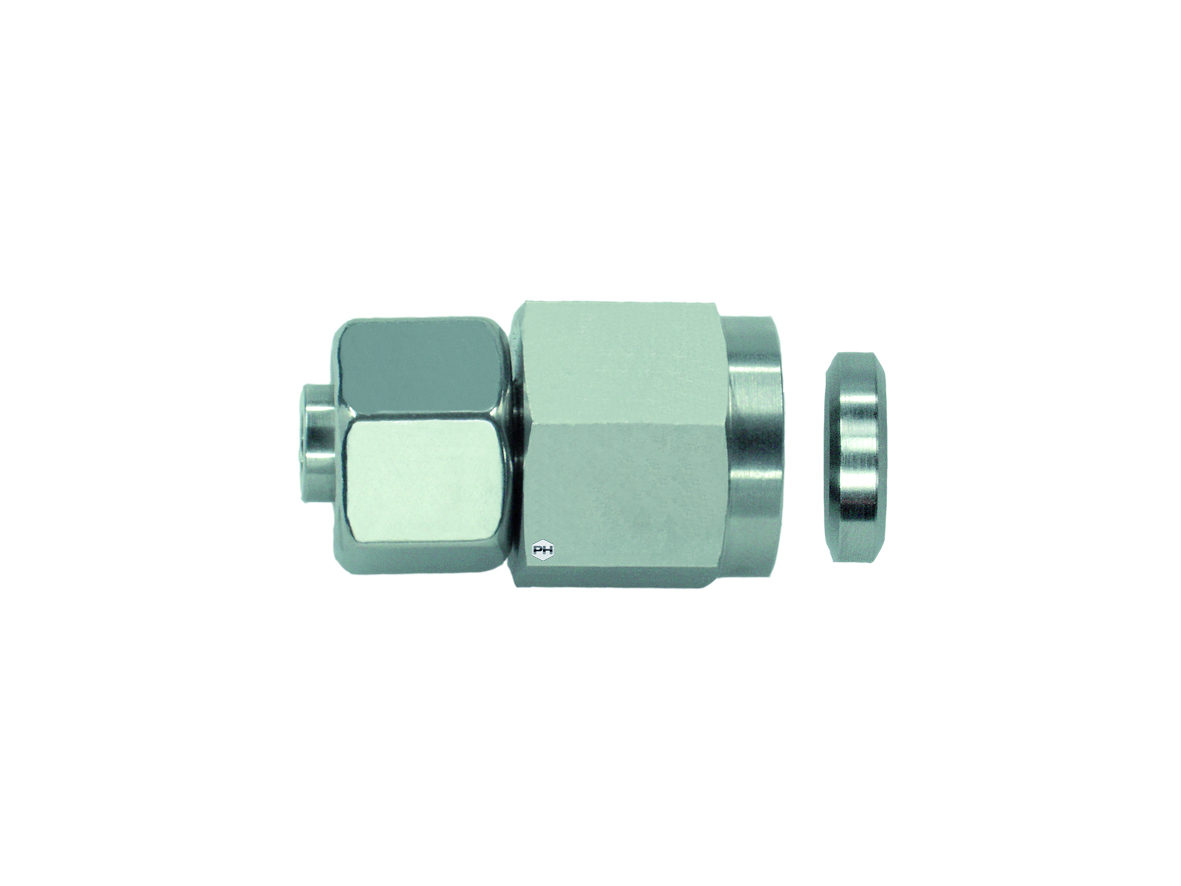

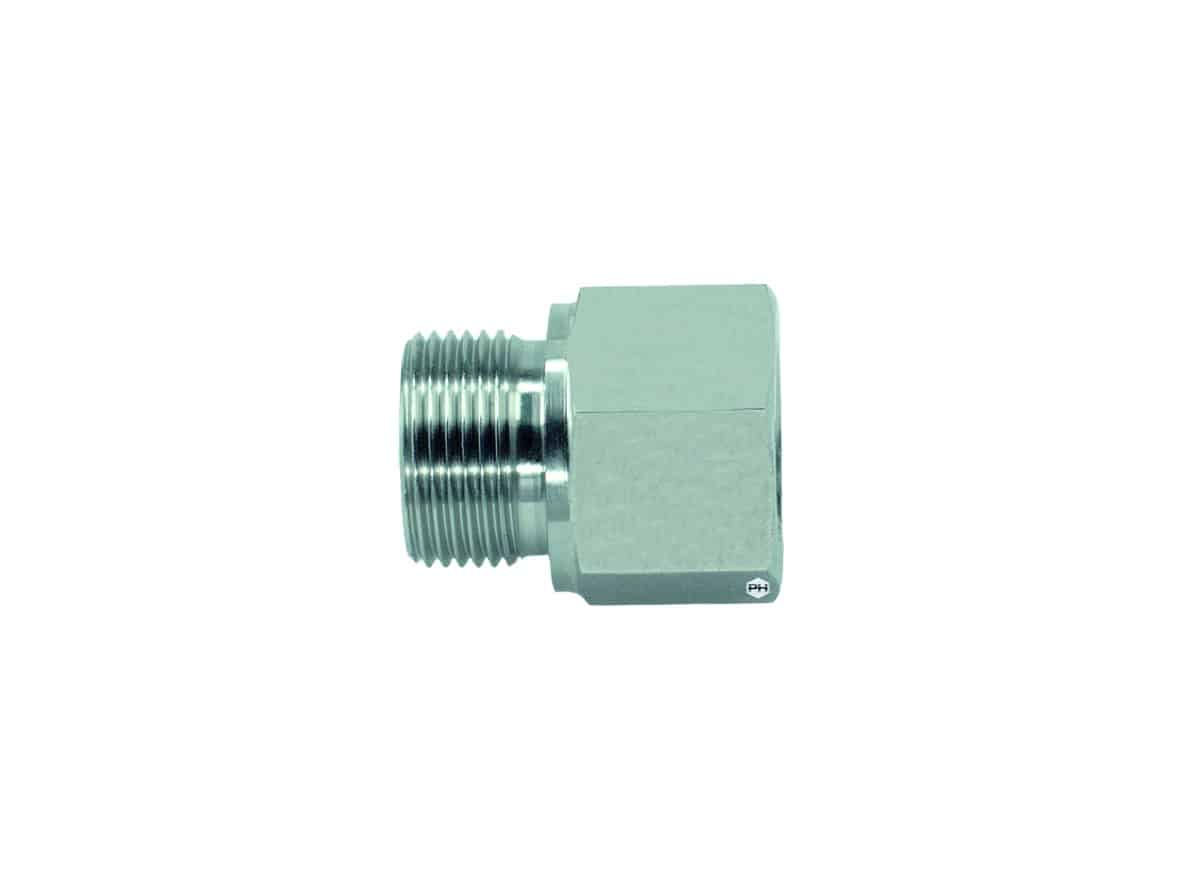

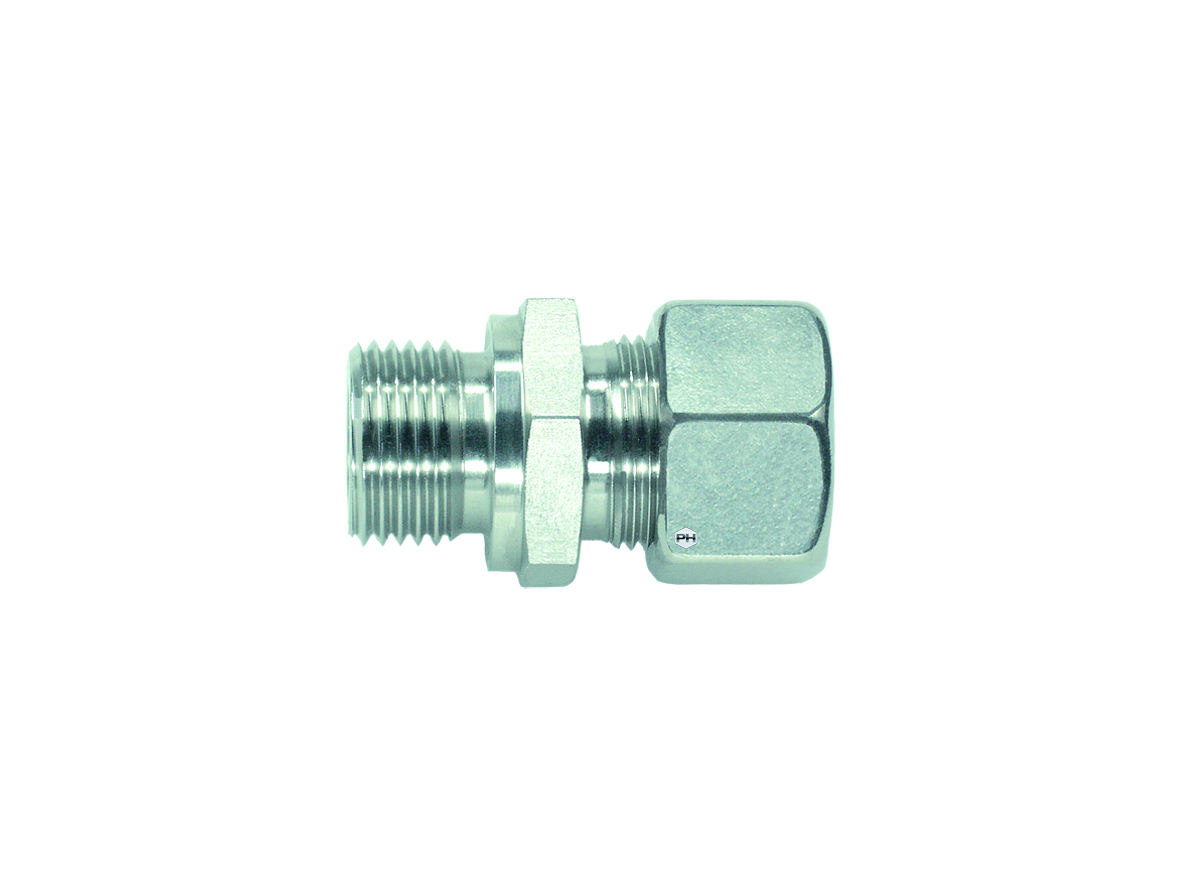

Straight female to male reducing coupling

-

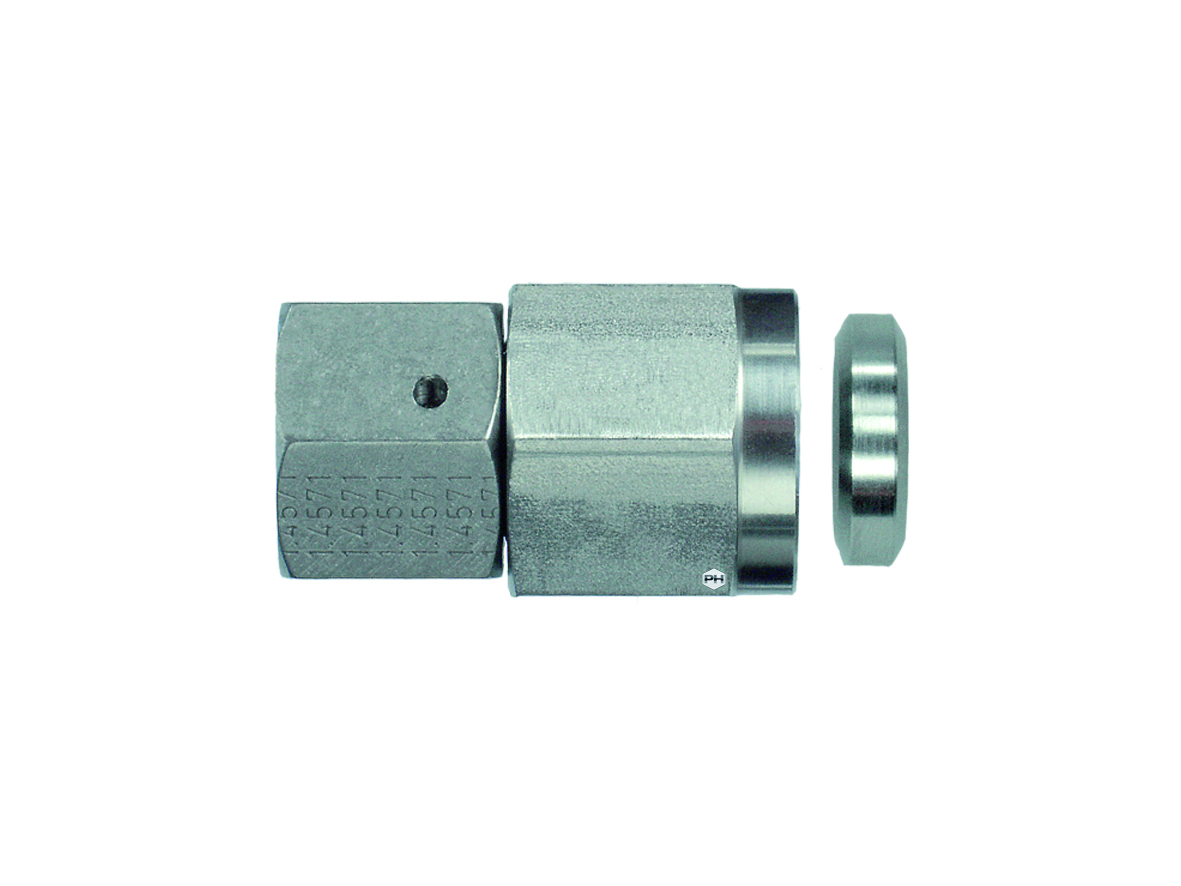

Straight female to male reducing coupling - body only

-

Straight female to male reducing coupling

-

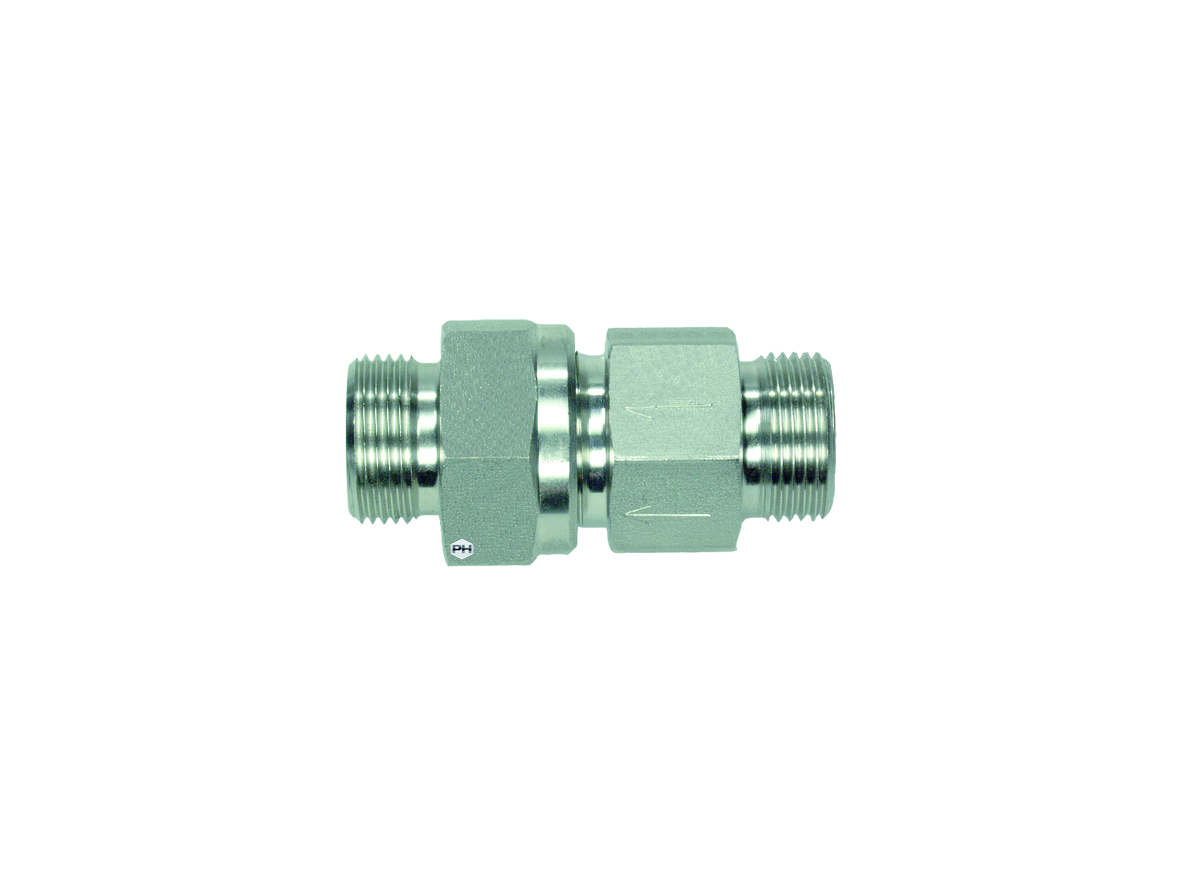

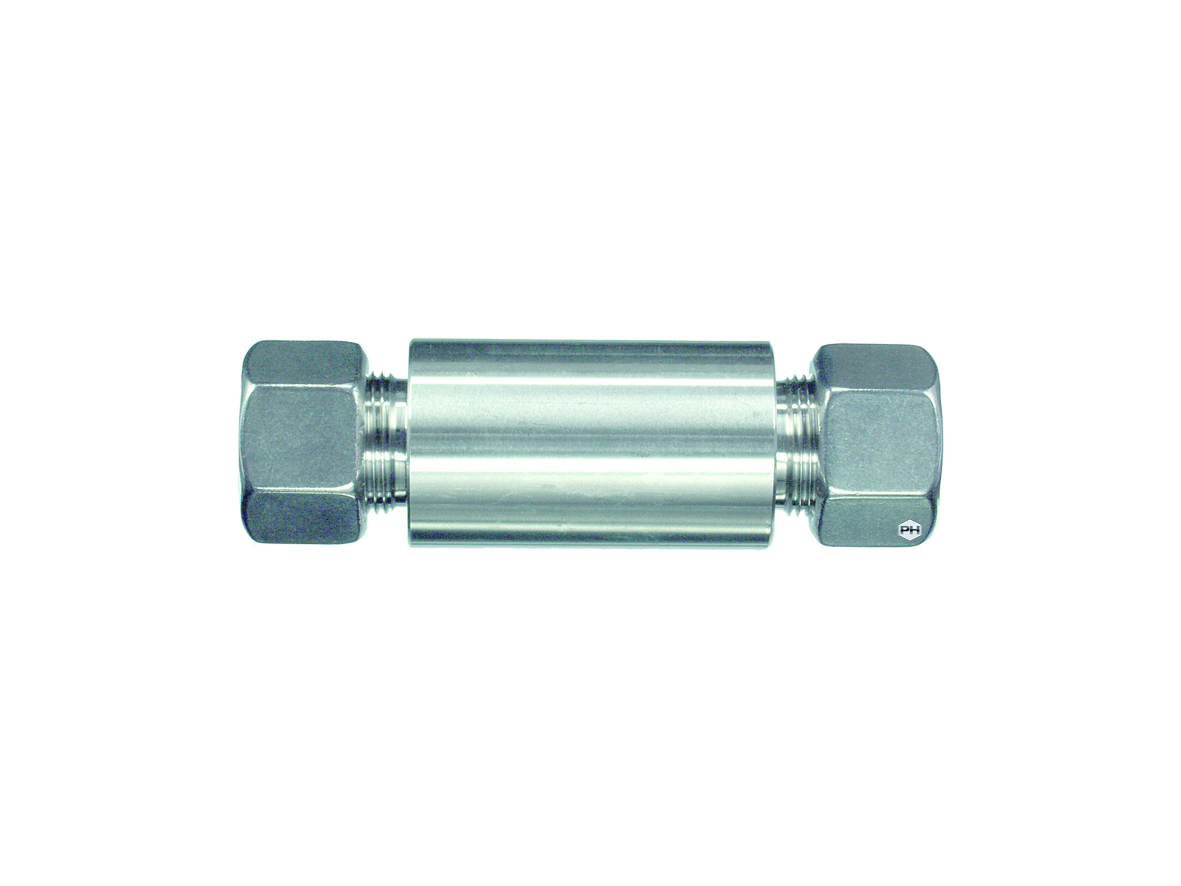

Non-return valve – compression both ends - body only

-

Non-return valve – compression both ends

-

Non-return valve – BSP parallel and NPT female

-

SAE flange seals

-

Adjustable BSP parallel female pressure gauge connector - body only

-

Adjustable BSP parallel female pressure gauge connector

-

Swivel female to gauge female

-

NPT female pressure gauge connector - body only

-

NPT female pressure gauge connector

-

BSP parallel female pressure gauge connector - body only

-

BSP parallel female pressure gauge connector

-

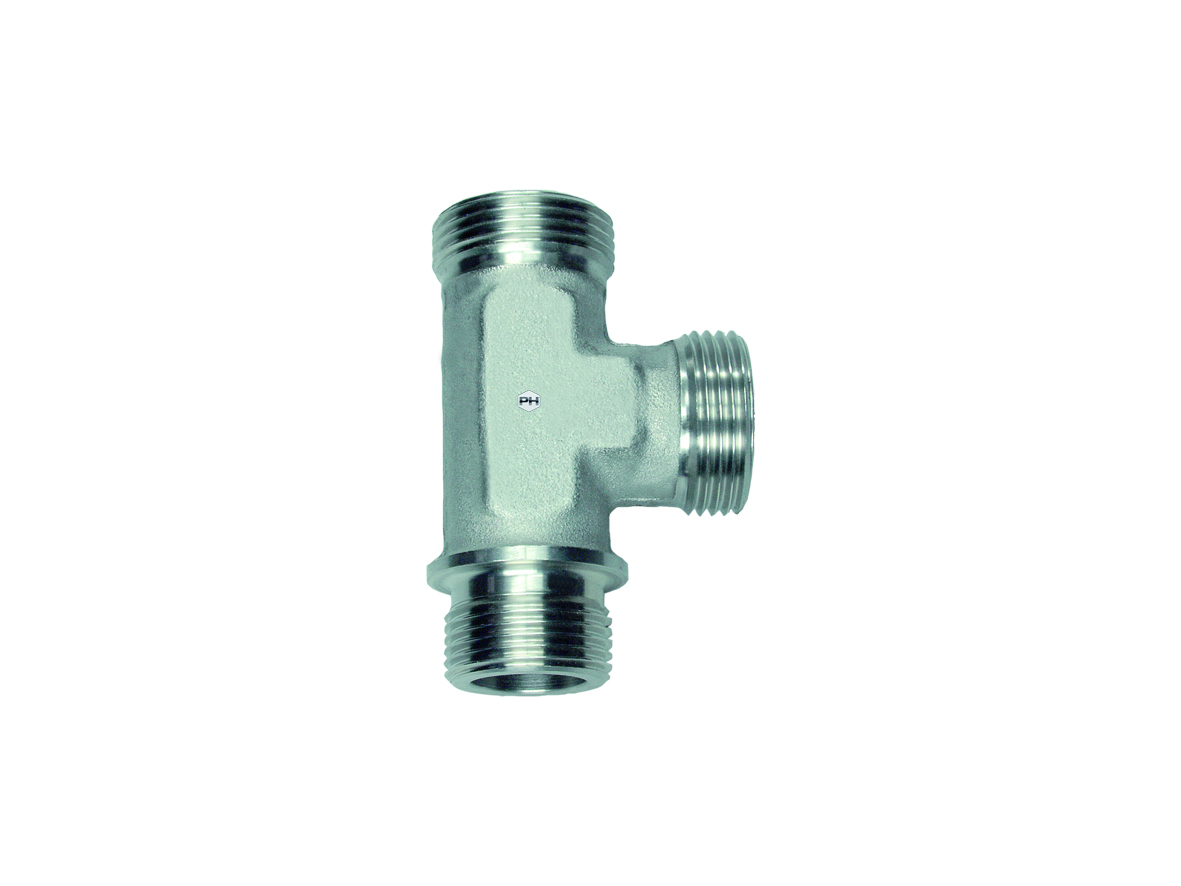

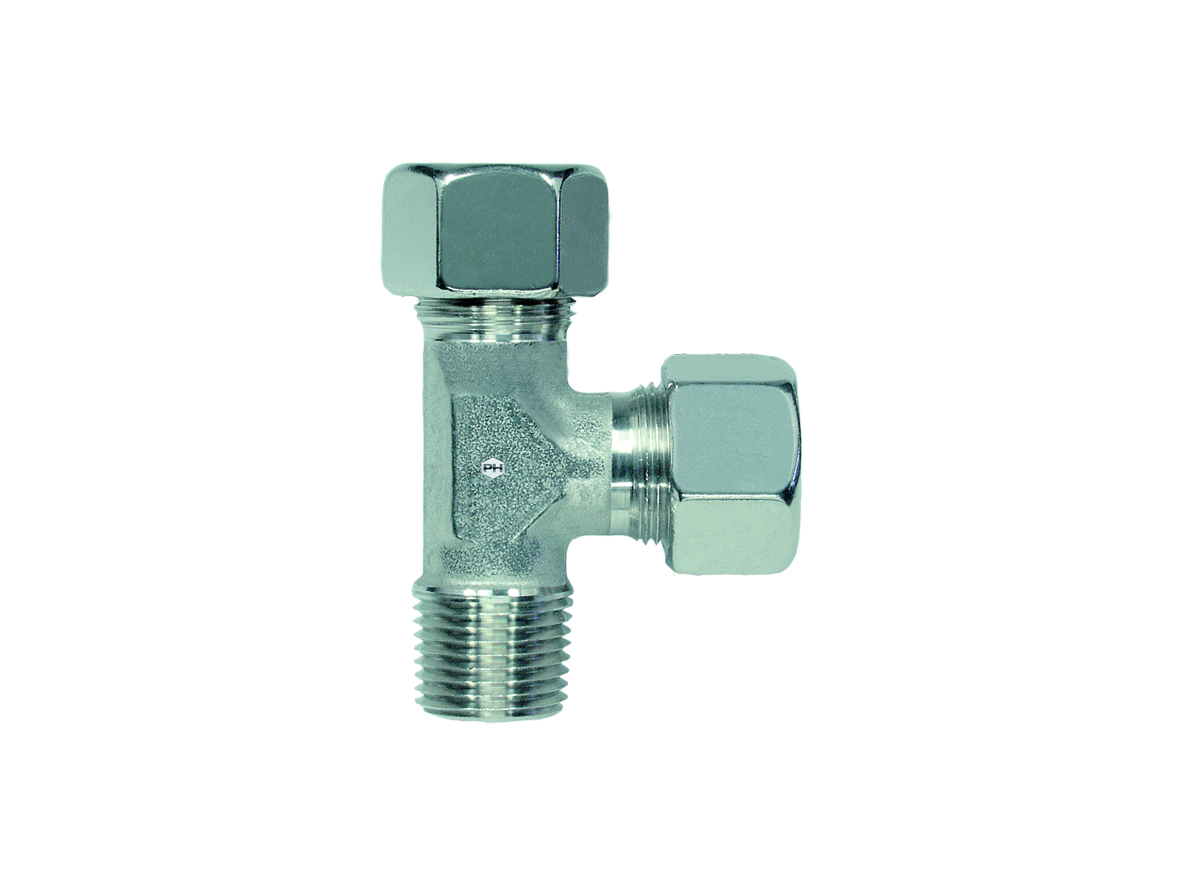

Male stud run tee to BSP parallel - body only

-

Male stud run tee to BSP parallel

-

Male stud run tee to metric taper - body only

-

Male stud run tee to metric taper

-

Male stud run tee to NPT - body only

-

Male stud run tee to NPT

-

Male stud run tee to BSP taper - body only

-

Male stud run tee to BSP taper

-

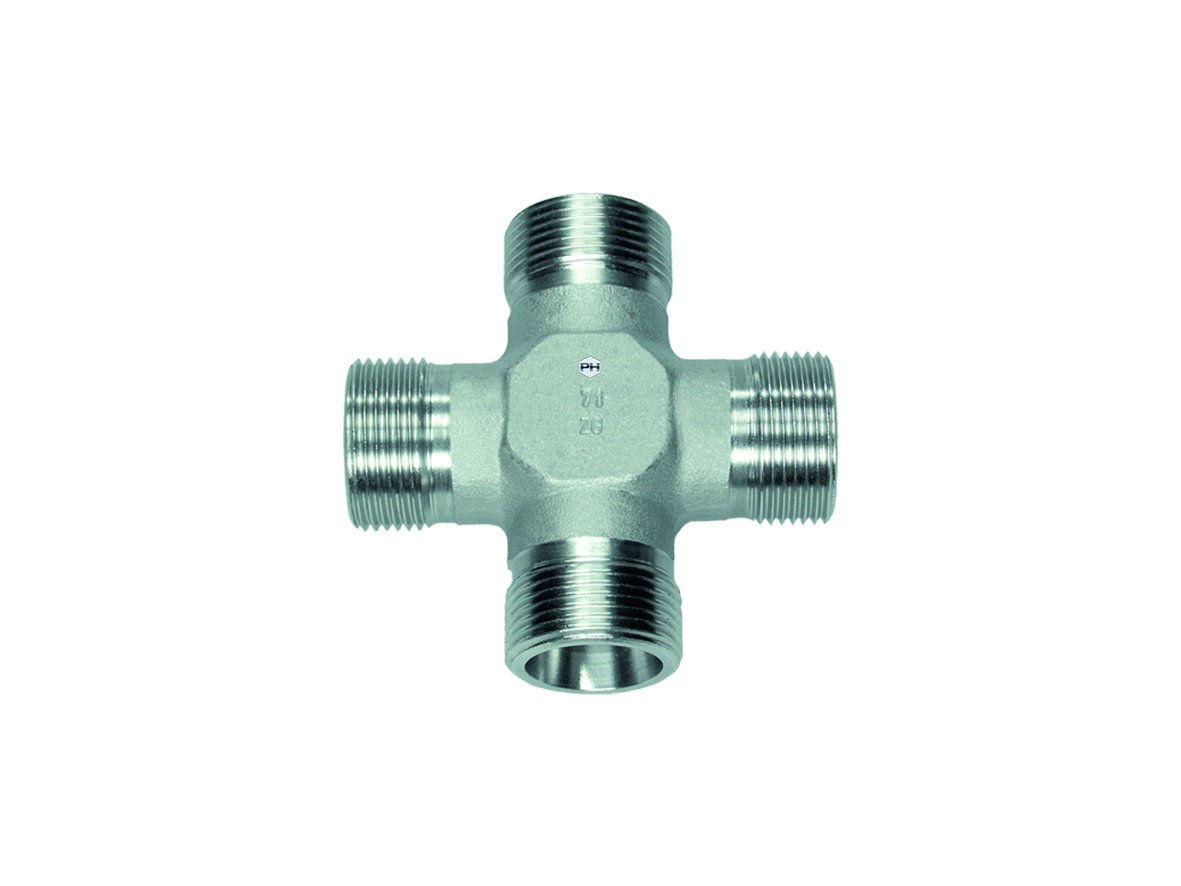

Equal cross - body only

-

Adjustable standpipe reducer

-

Adjustable standpipe reducer - body only

-

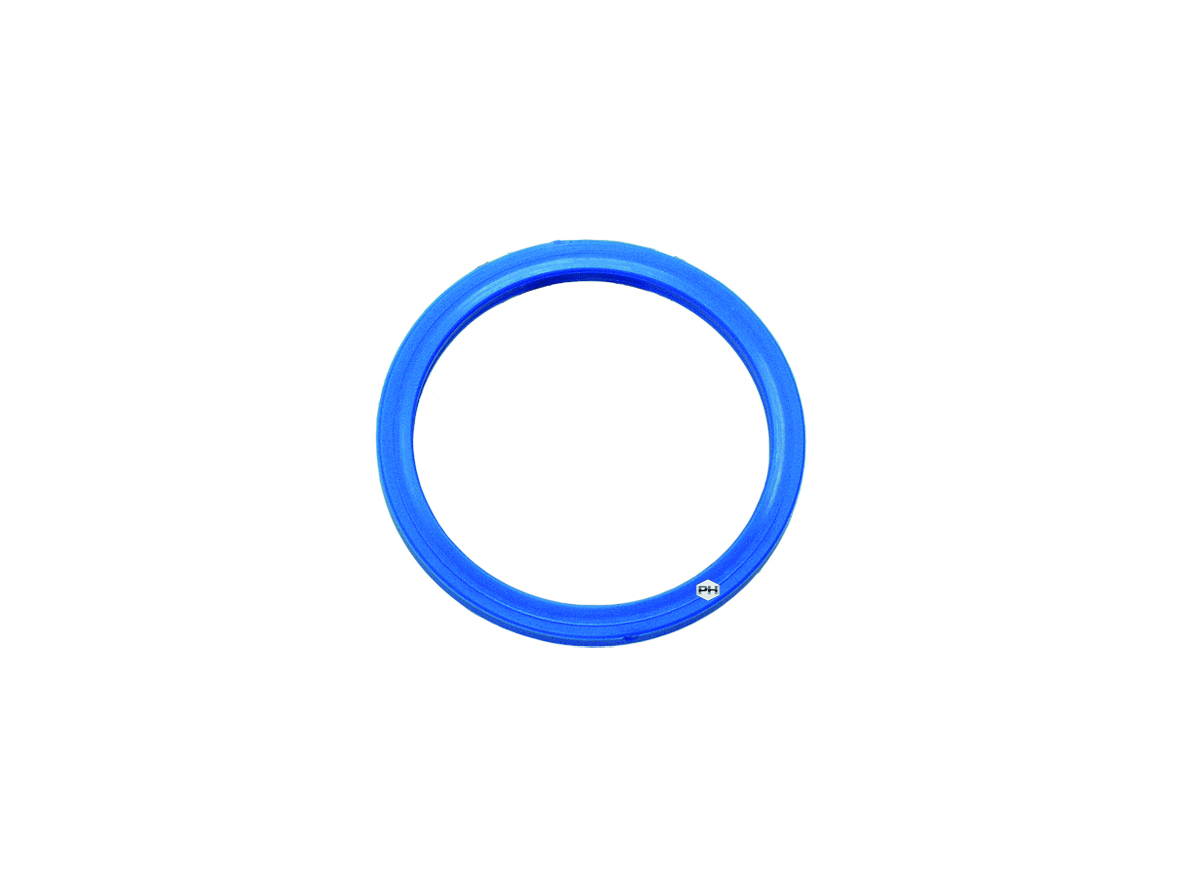

PTFE sealing ring for banjo fittings

-

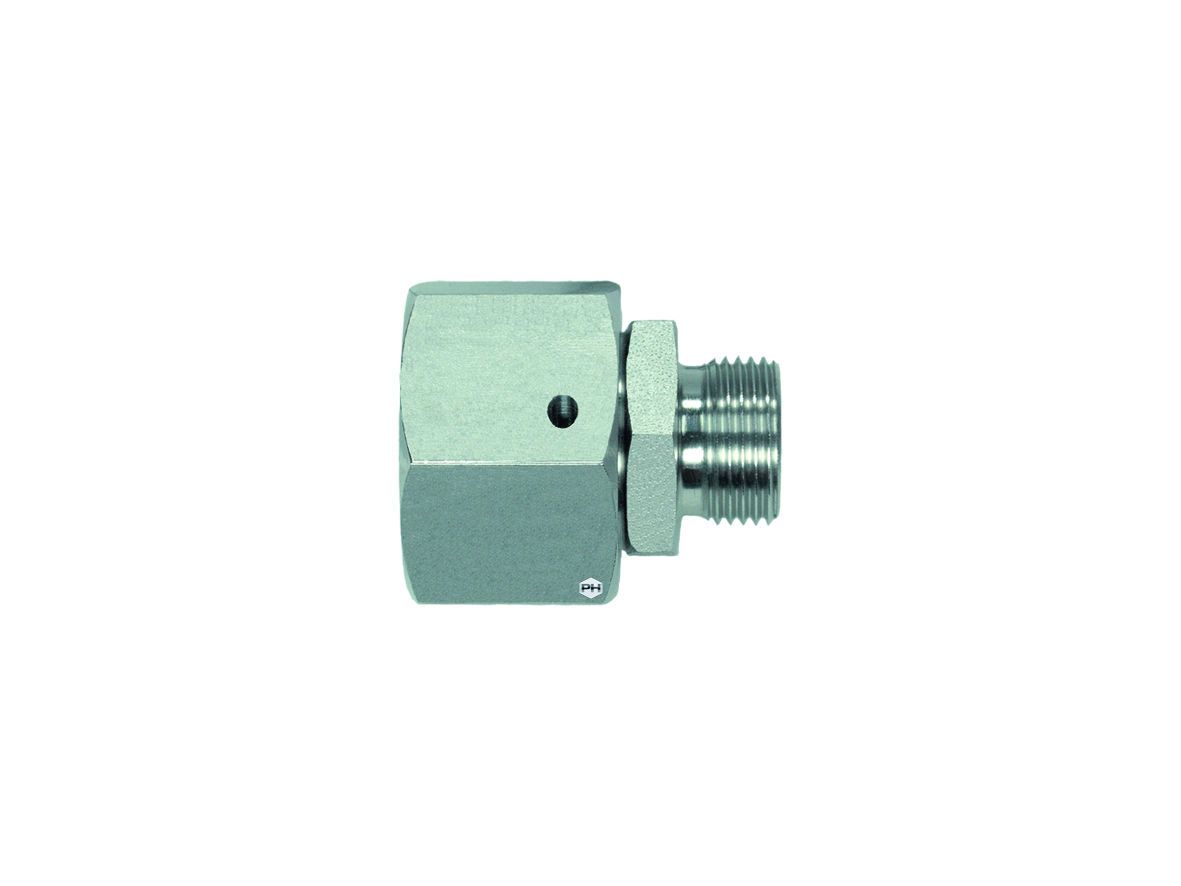

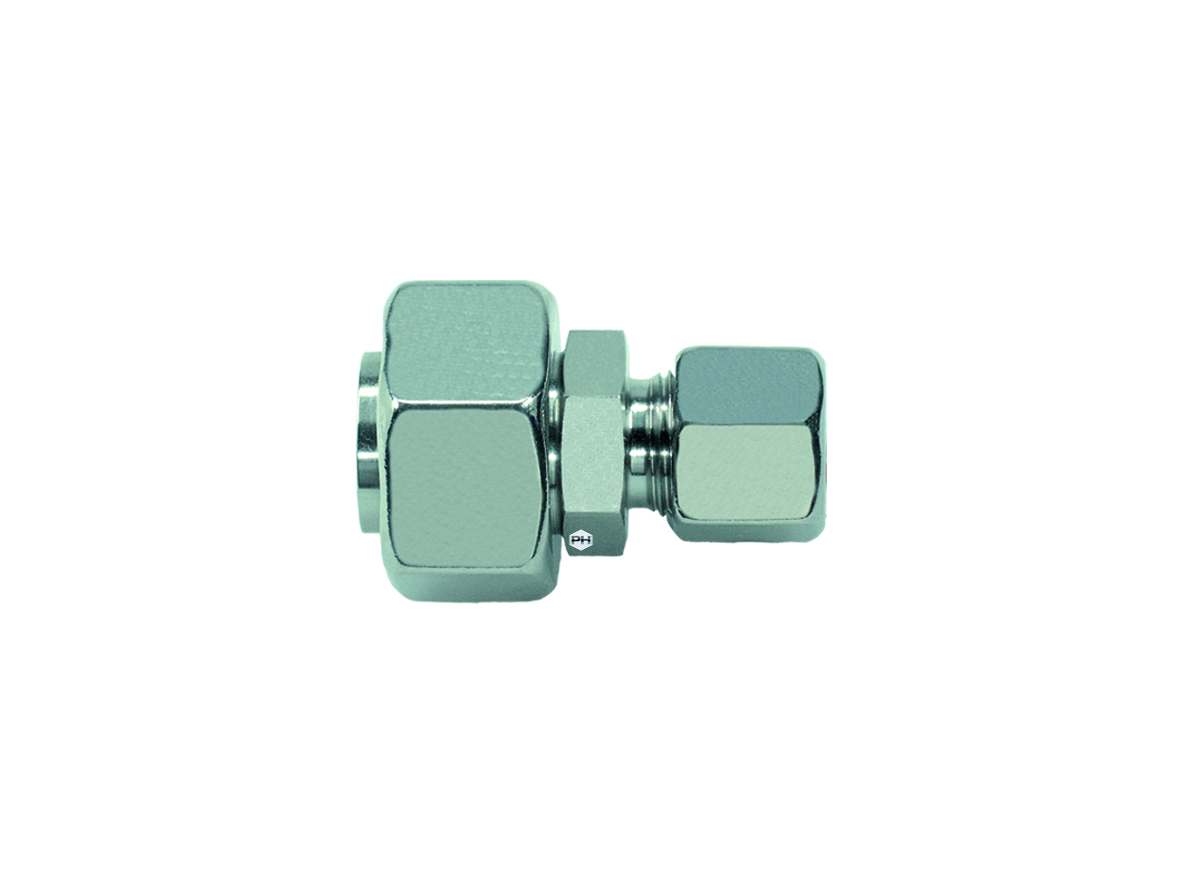

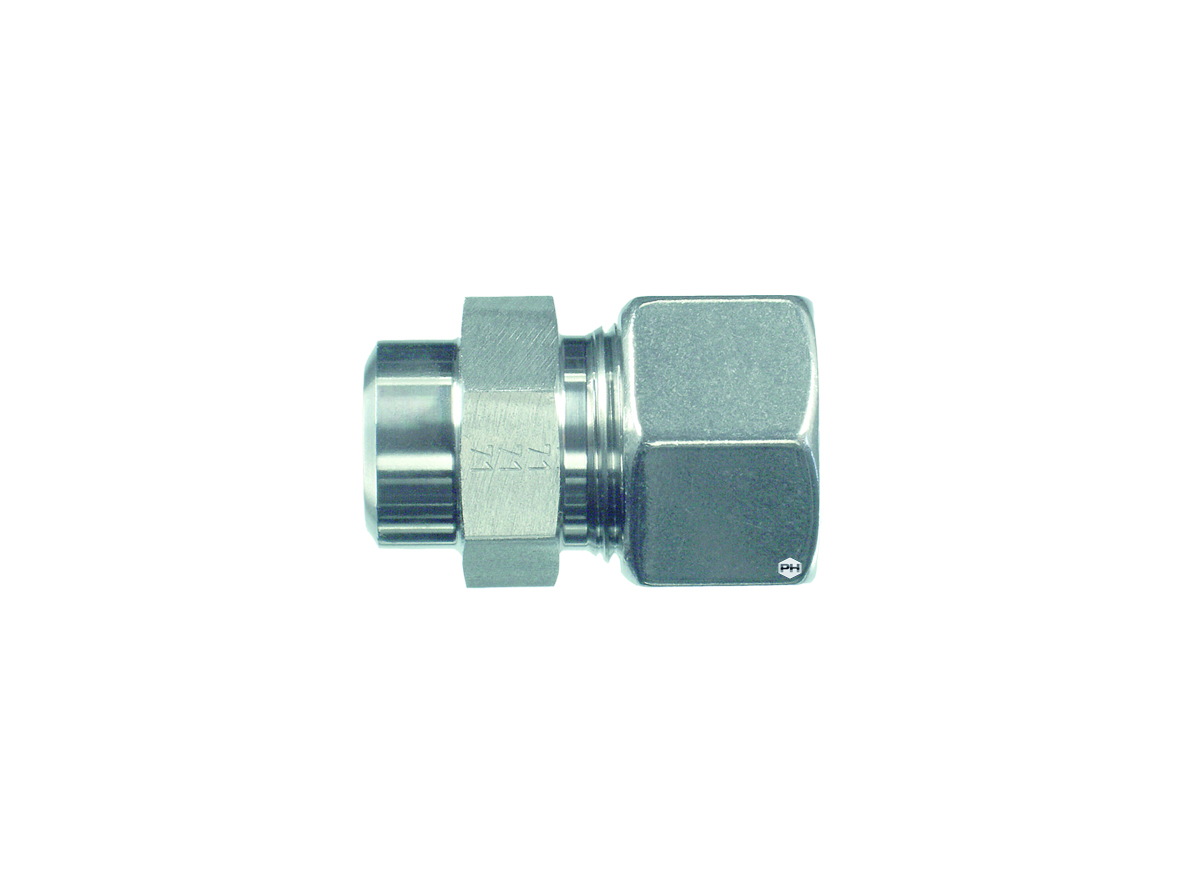

Straight female female reducing coupling (L to L & S to S series)

-

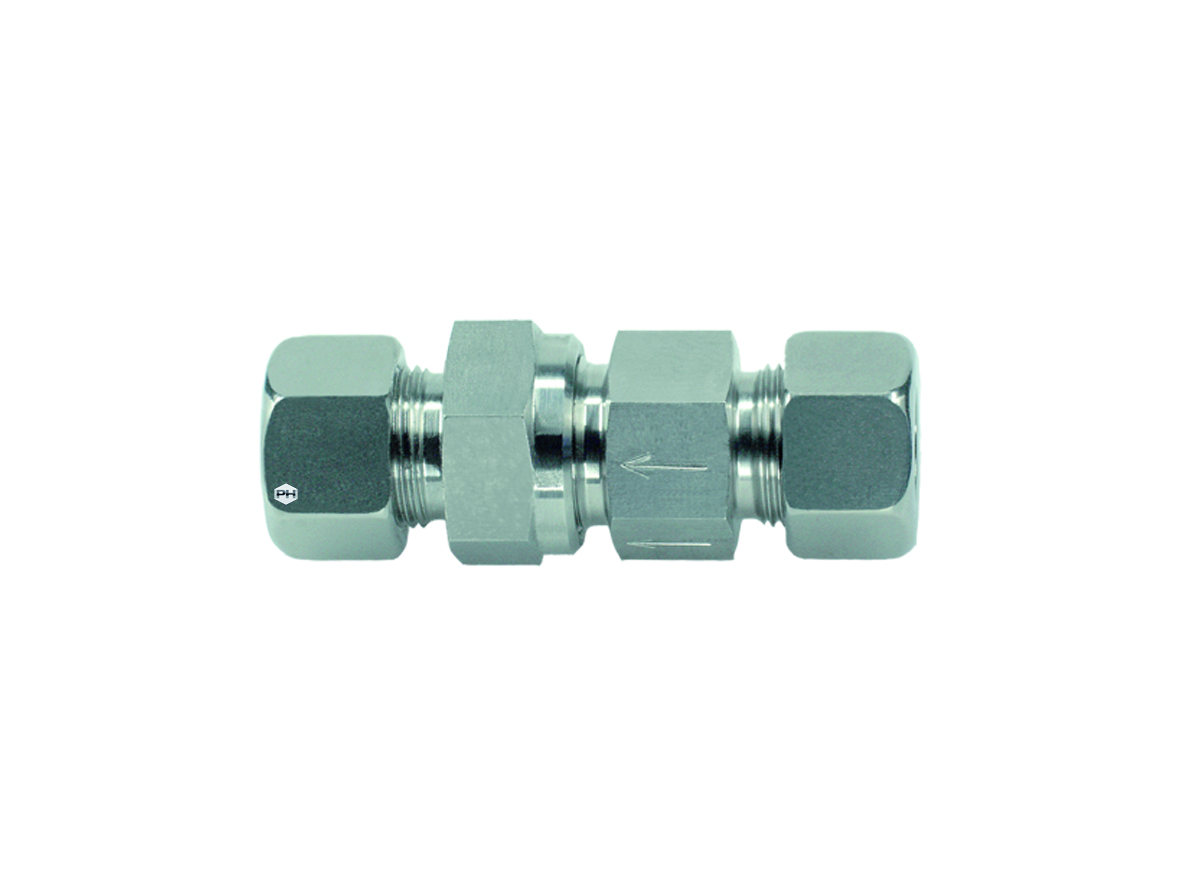

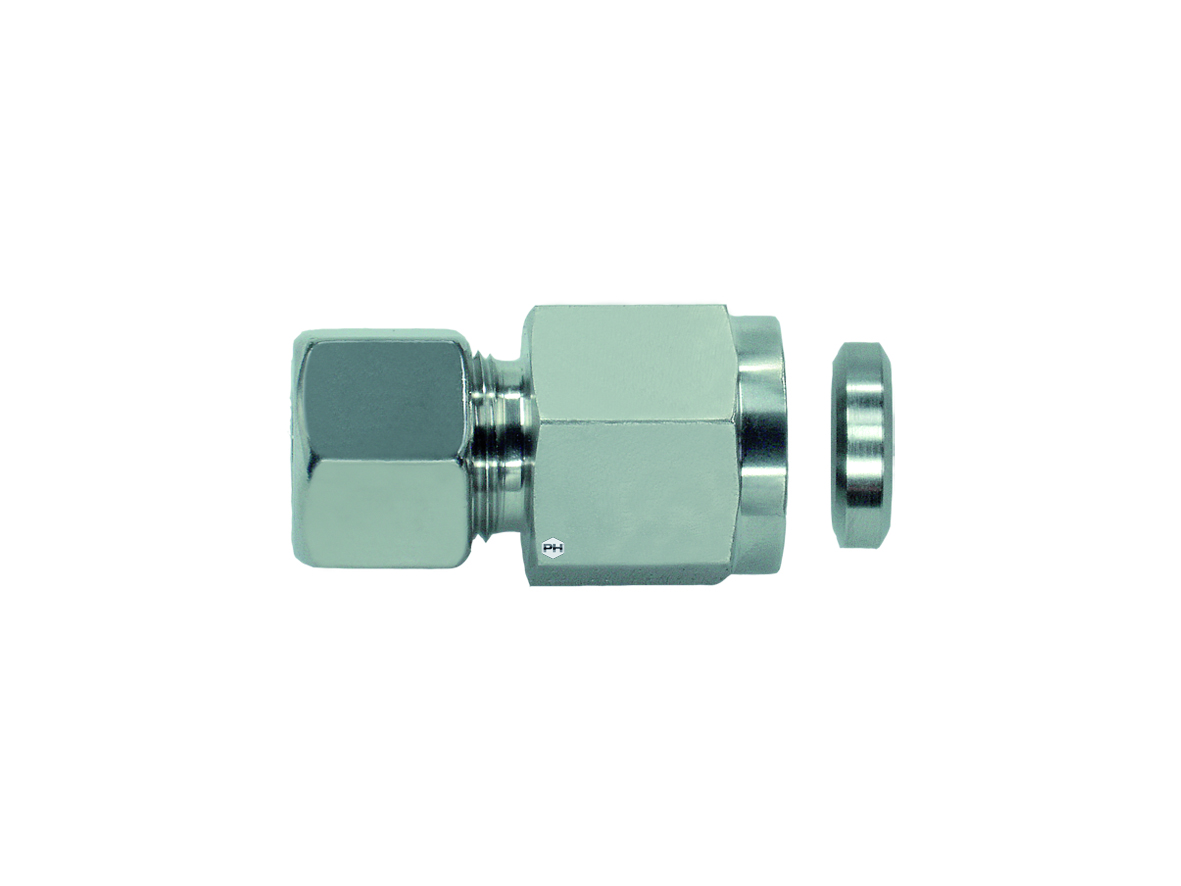

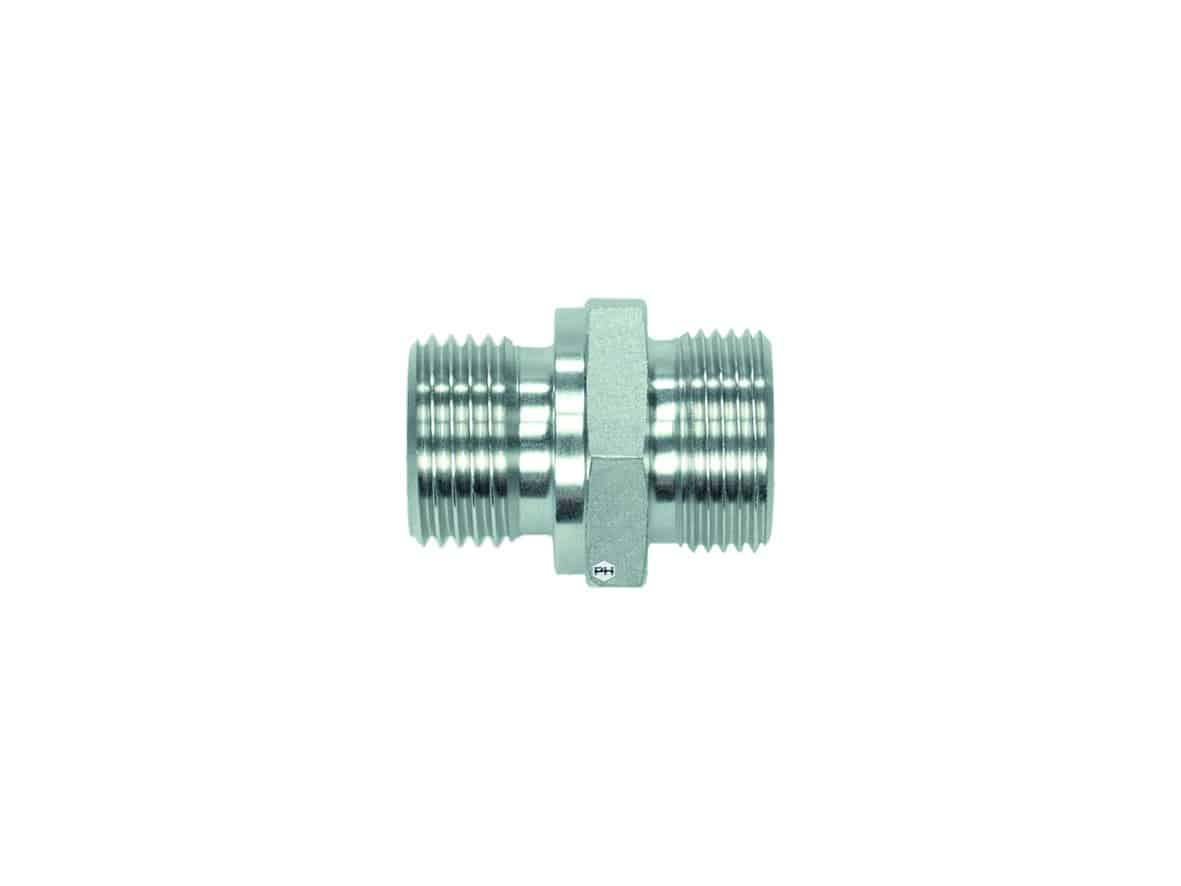

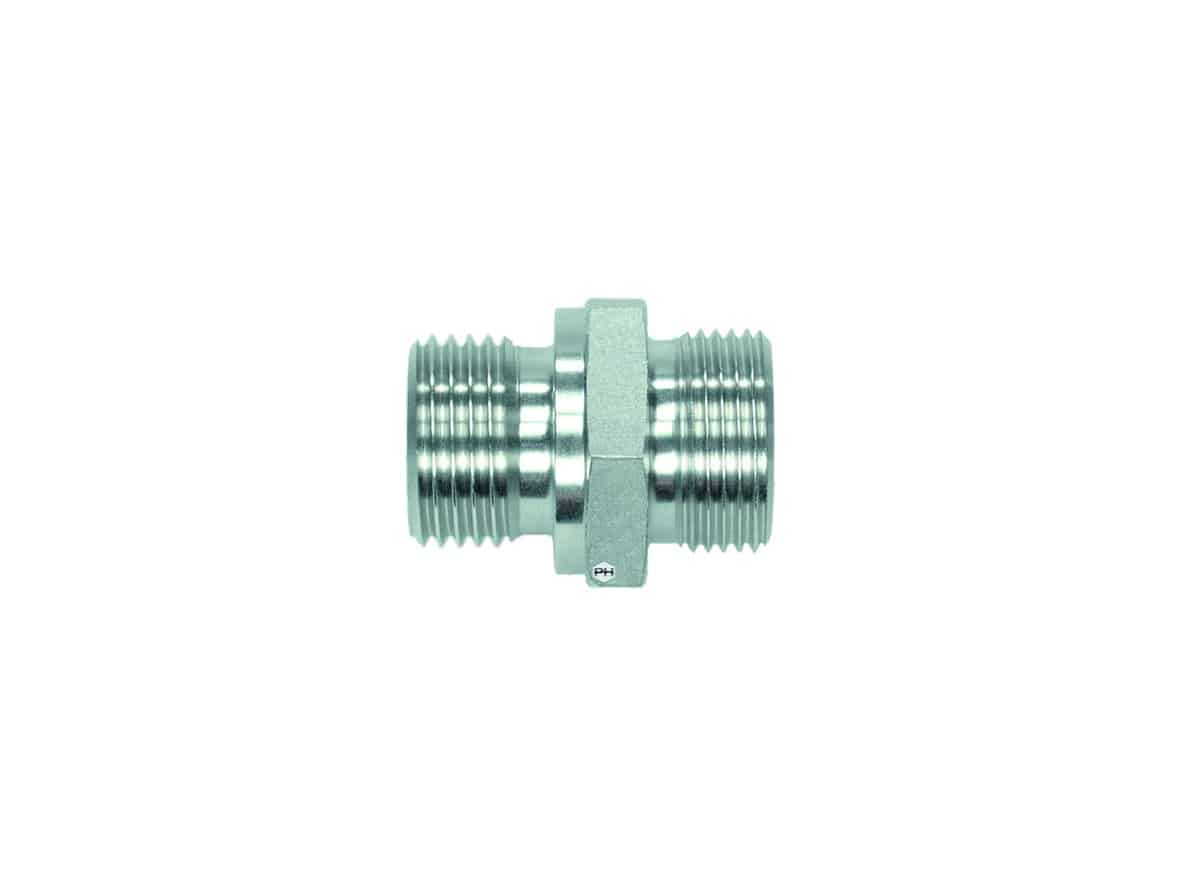

Straight coupling body only

-

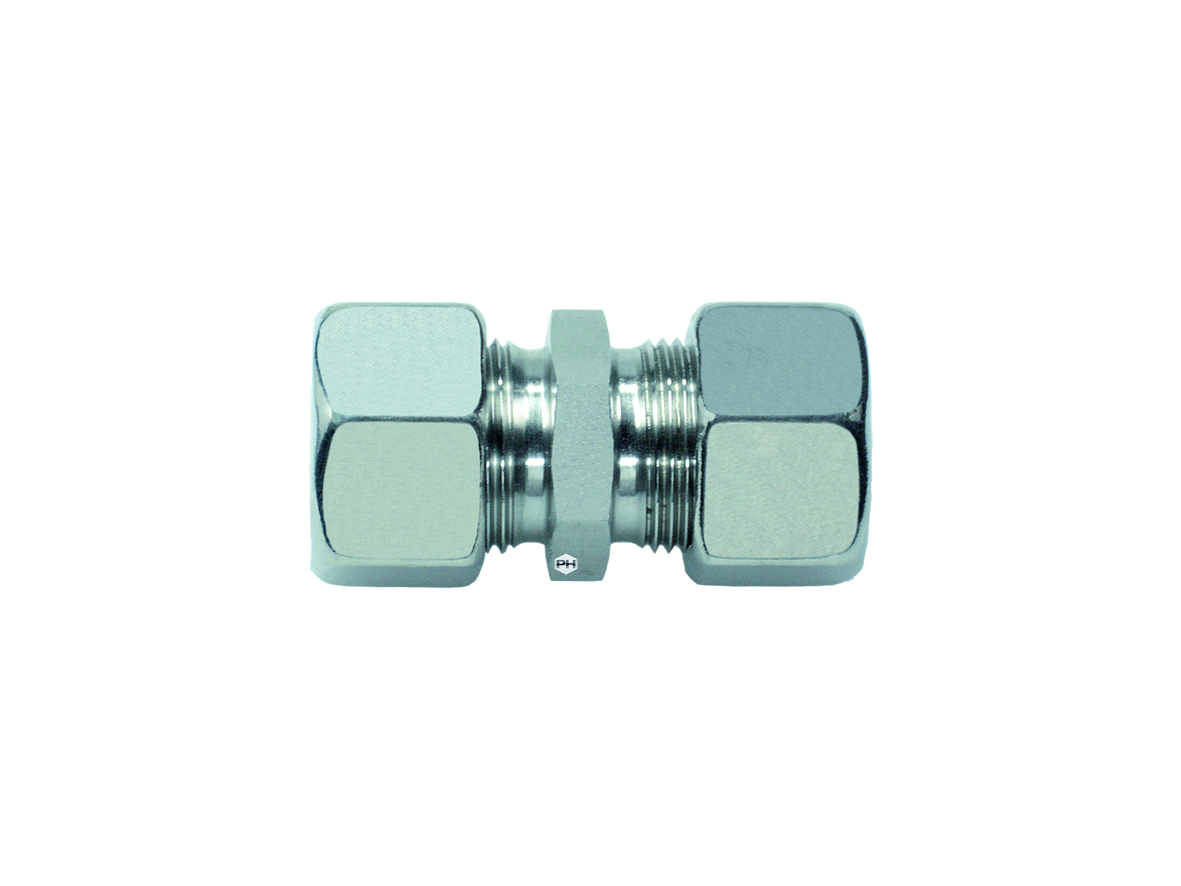

Straight female female coupling

-

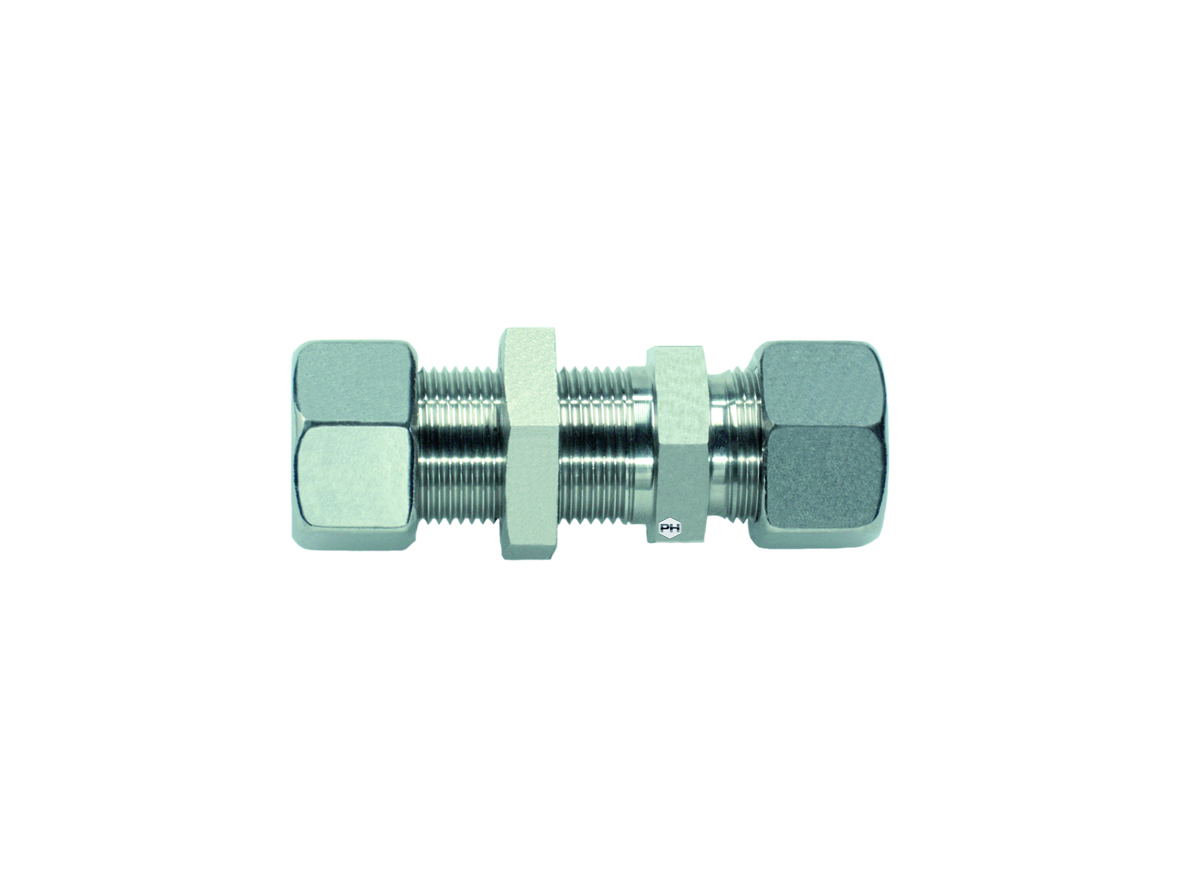

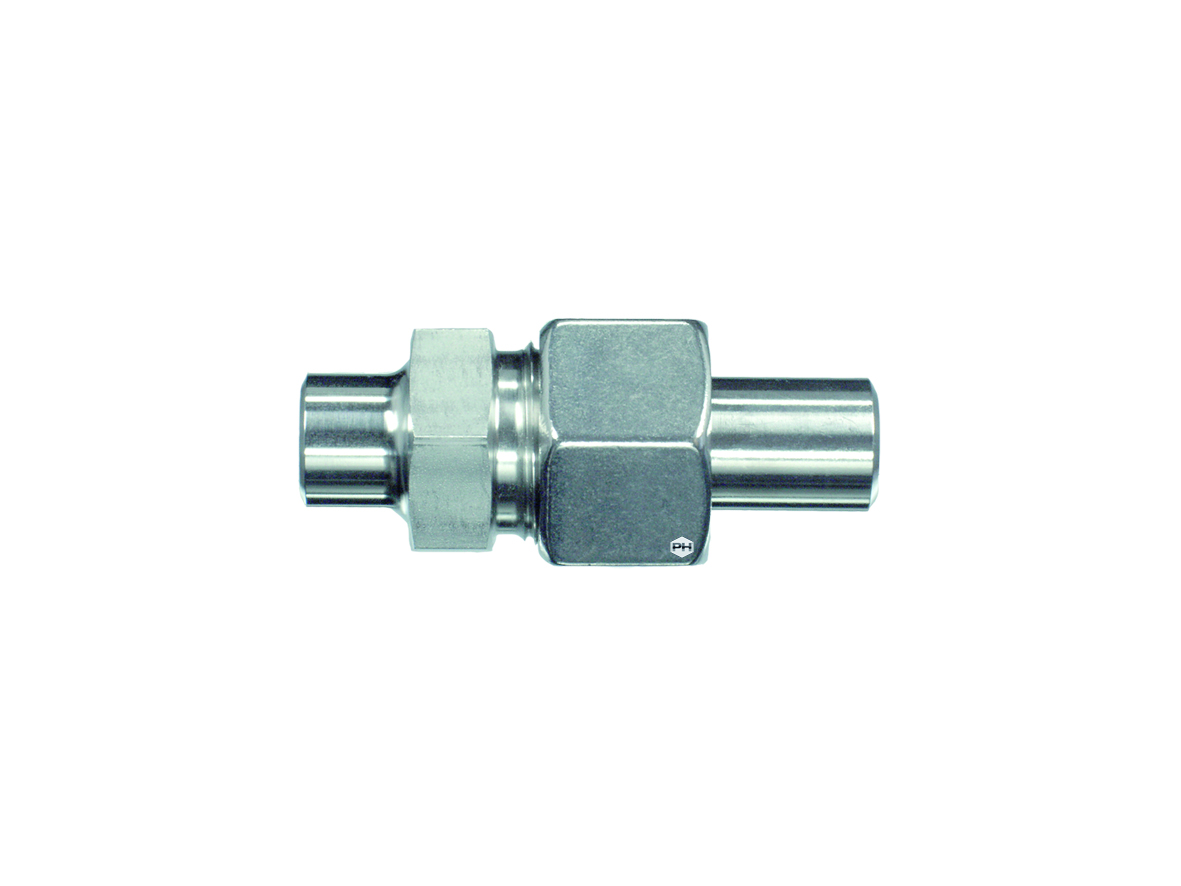

Bulkhead coupling body only

-

Bulkhead coupling

-

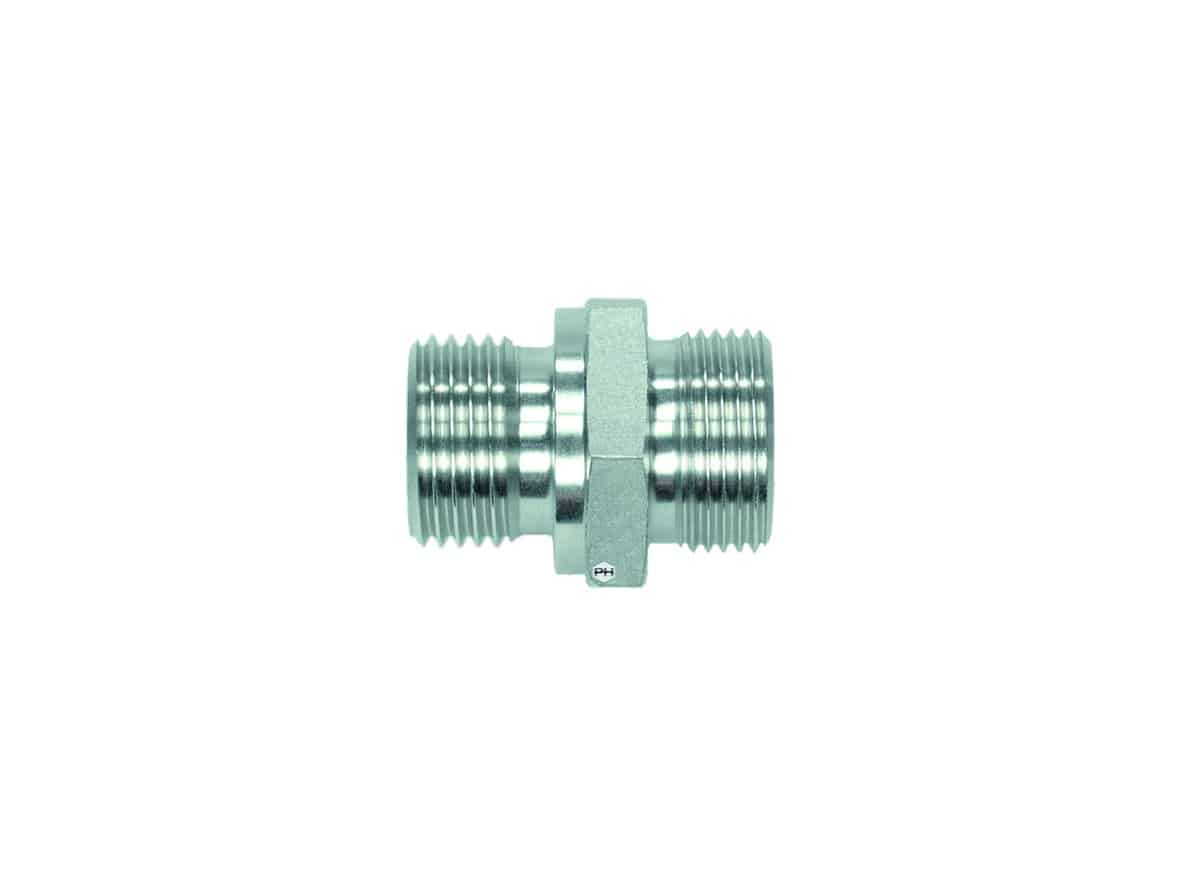

Straight reducing coupling body only

-

Straight reducing coupling

-

Straight reducing coupling body only

-

Straight reducing coupling

-

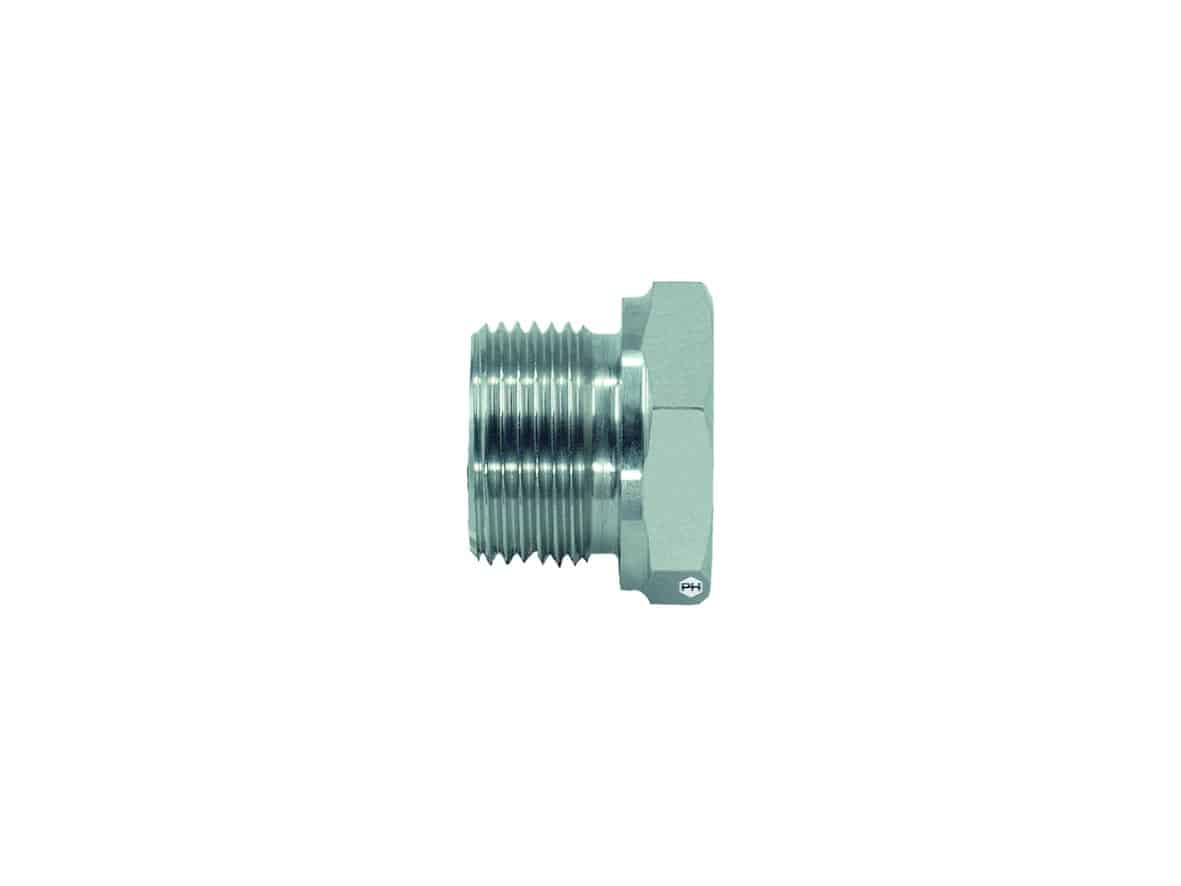

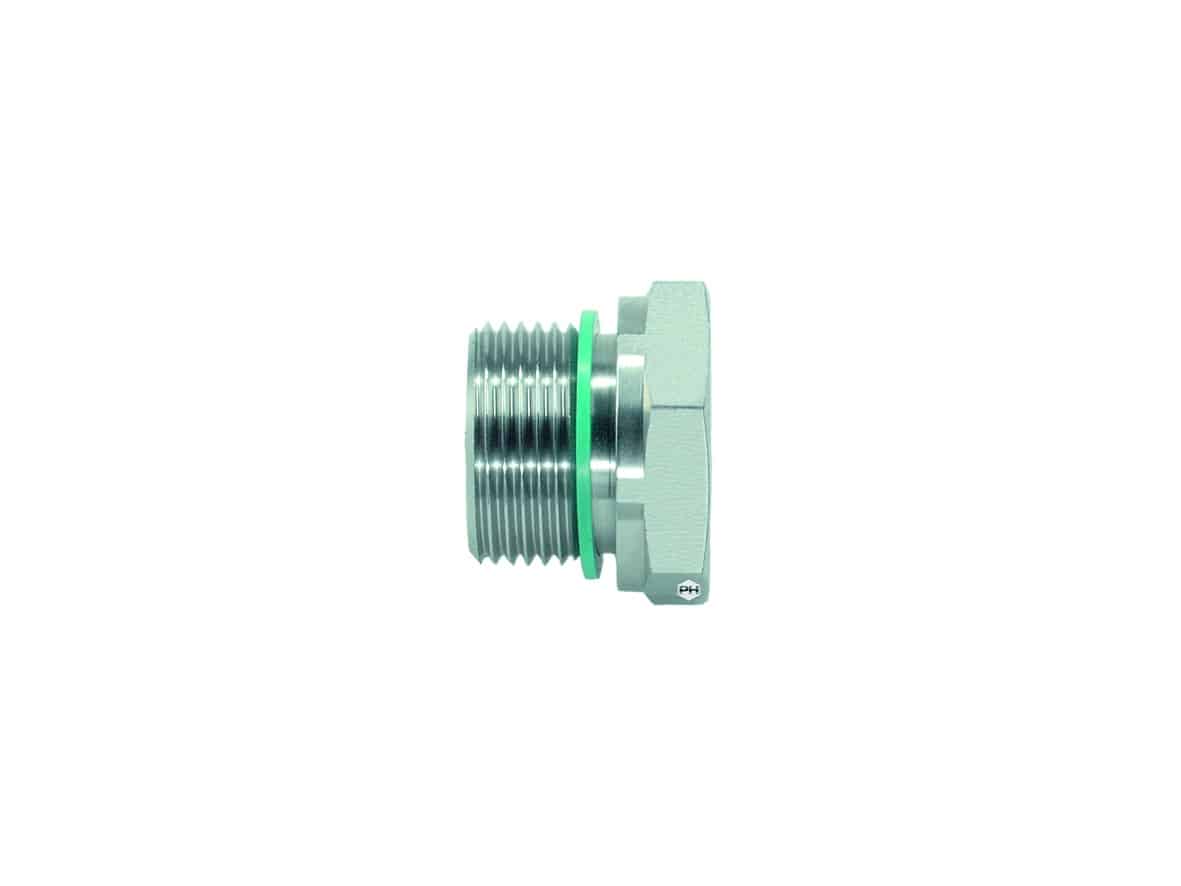

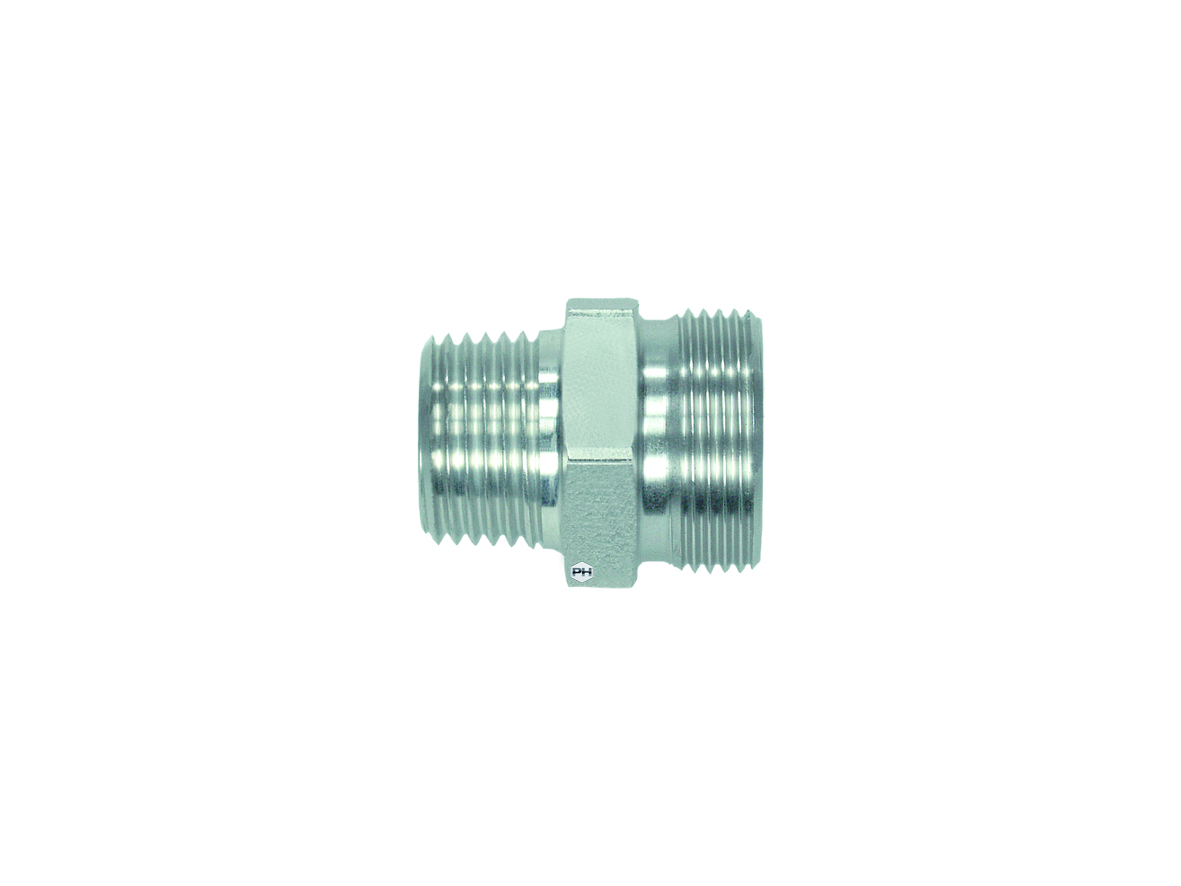

Hexagonal reducing bush – BSP parallel Form B

-

Hexagonal reducing bush – BSP parallel Form A

-

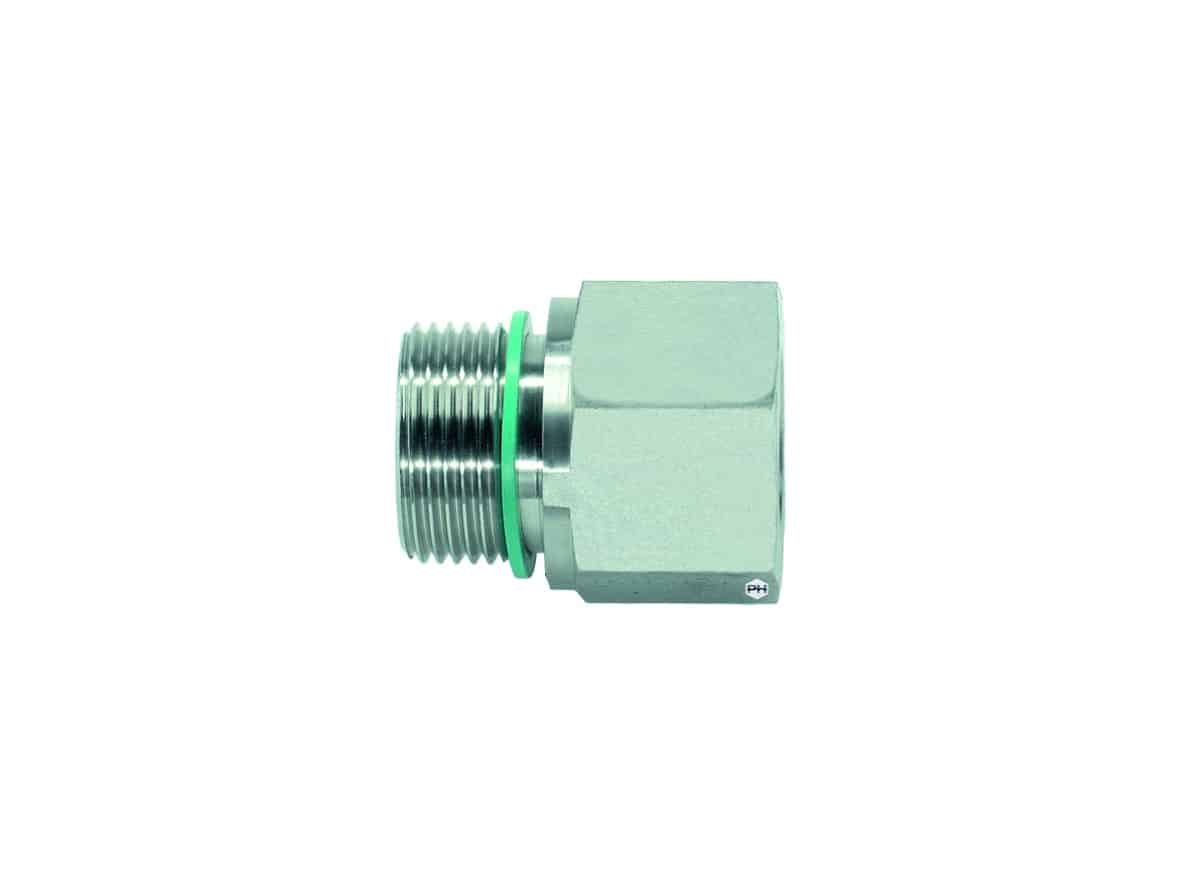

Hexagonal reducing bush – BSP parallel – with captive seal Form B

-

Hexagonal reducing bush – BSP parallel – with captive seal Form A

-

Locknut

-

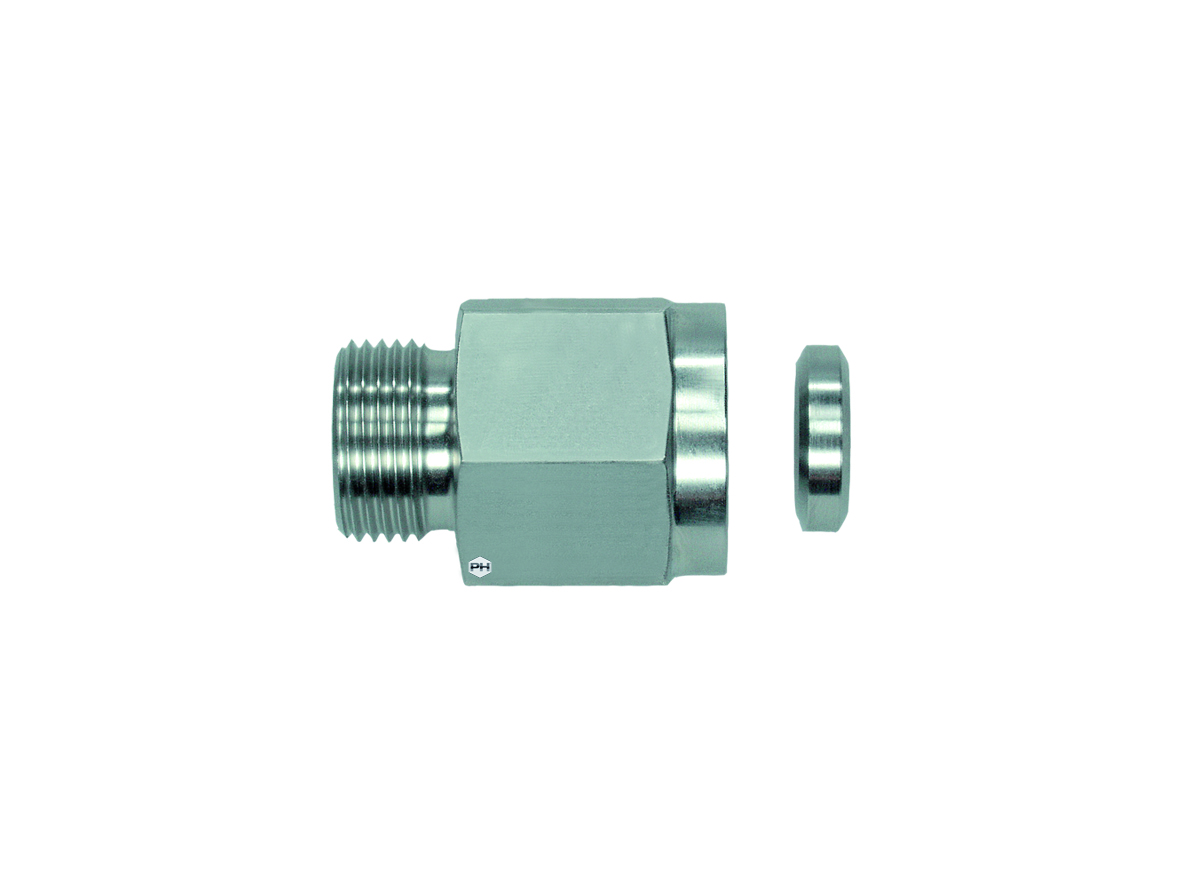

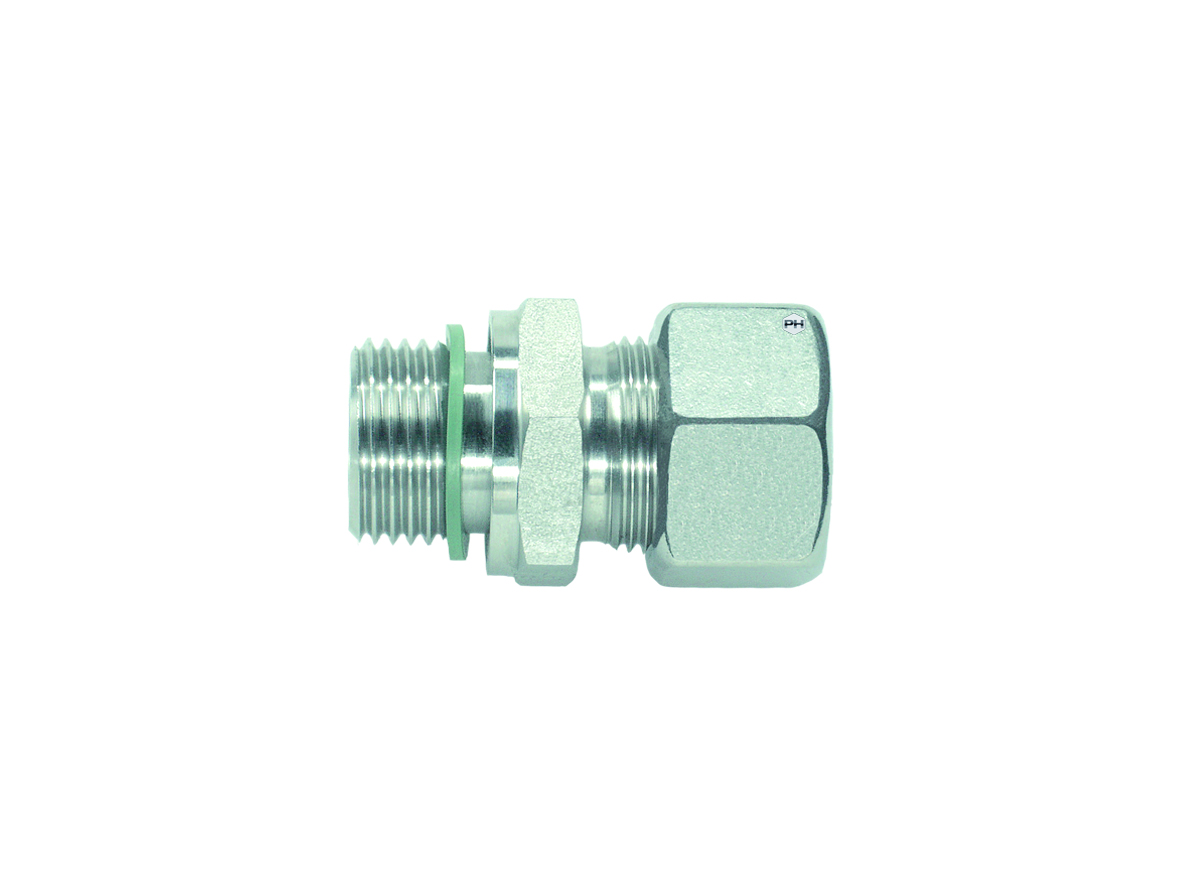

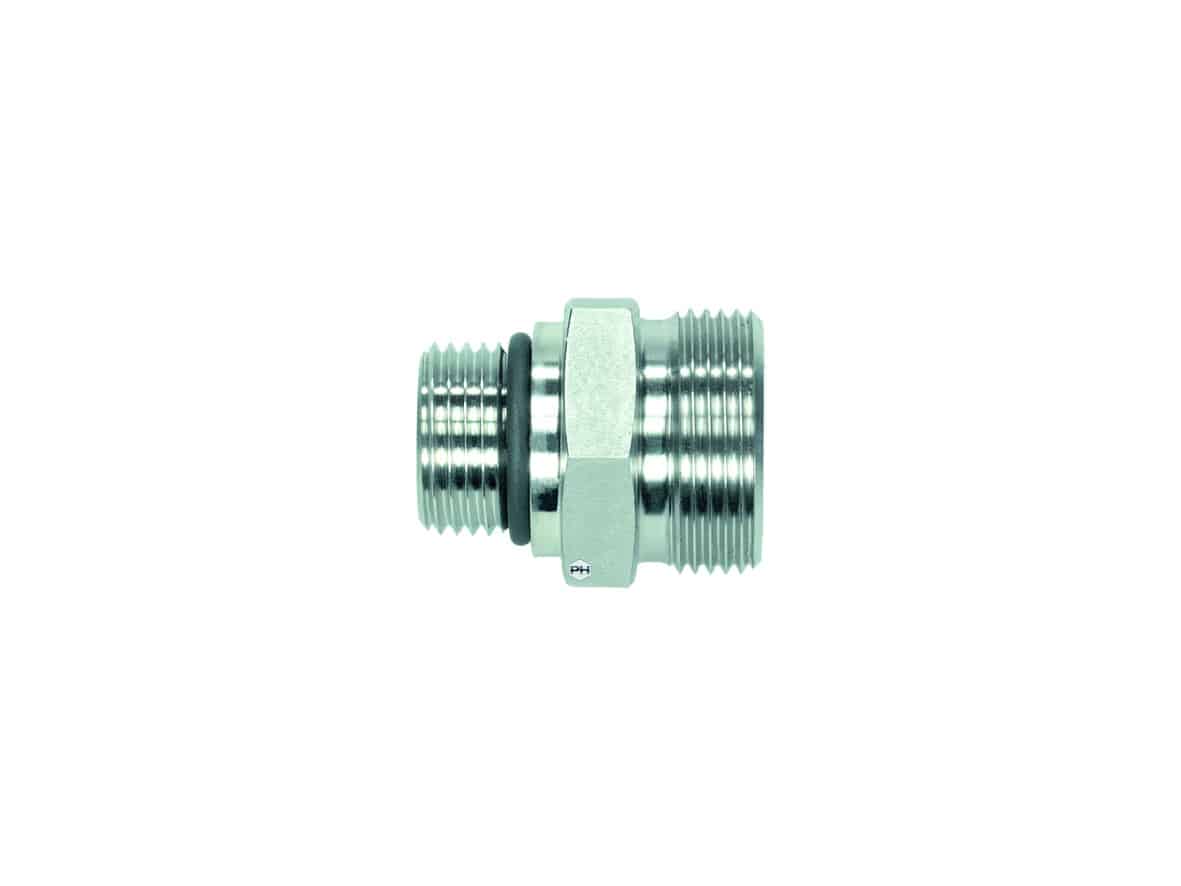

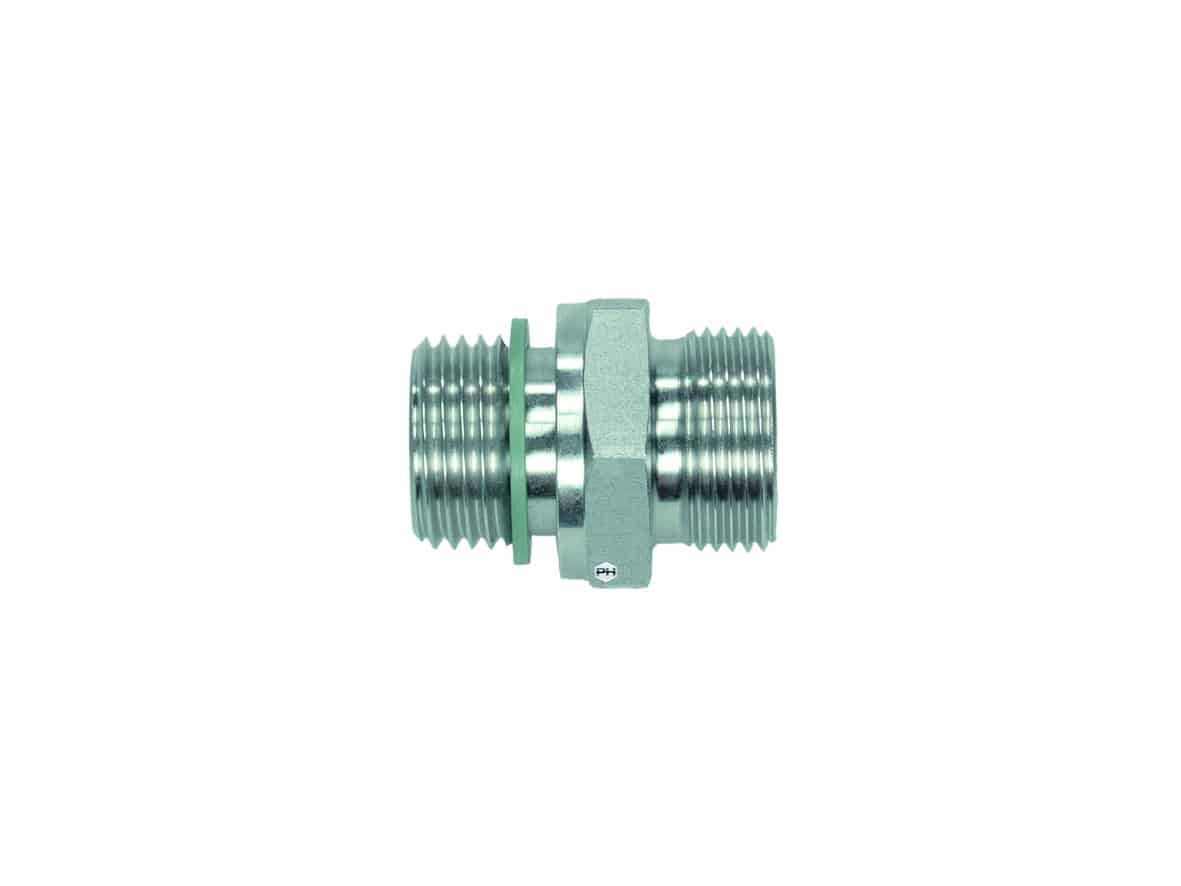

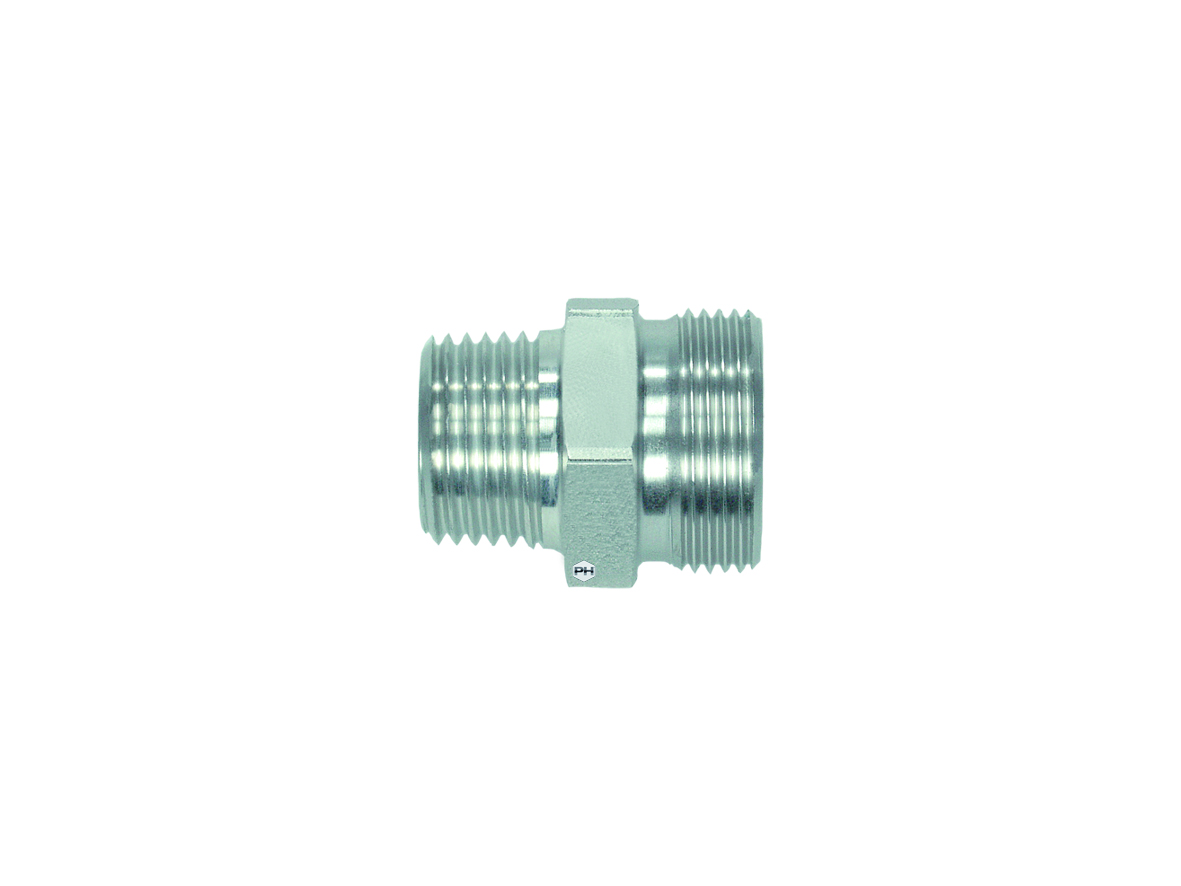

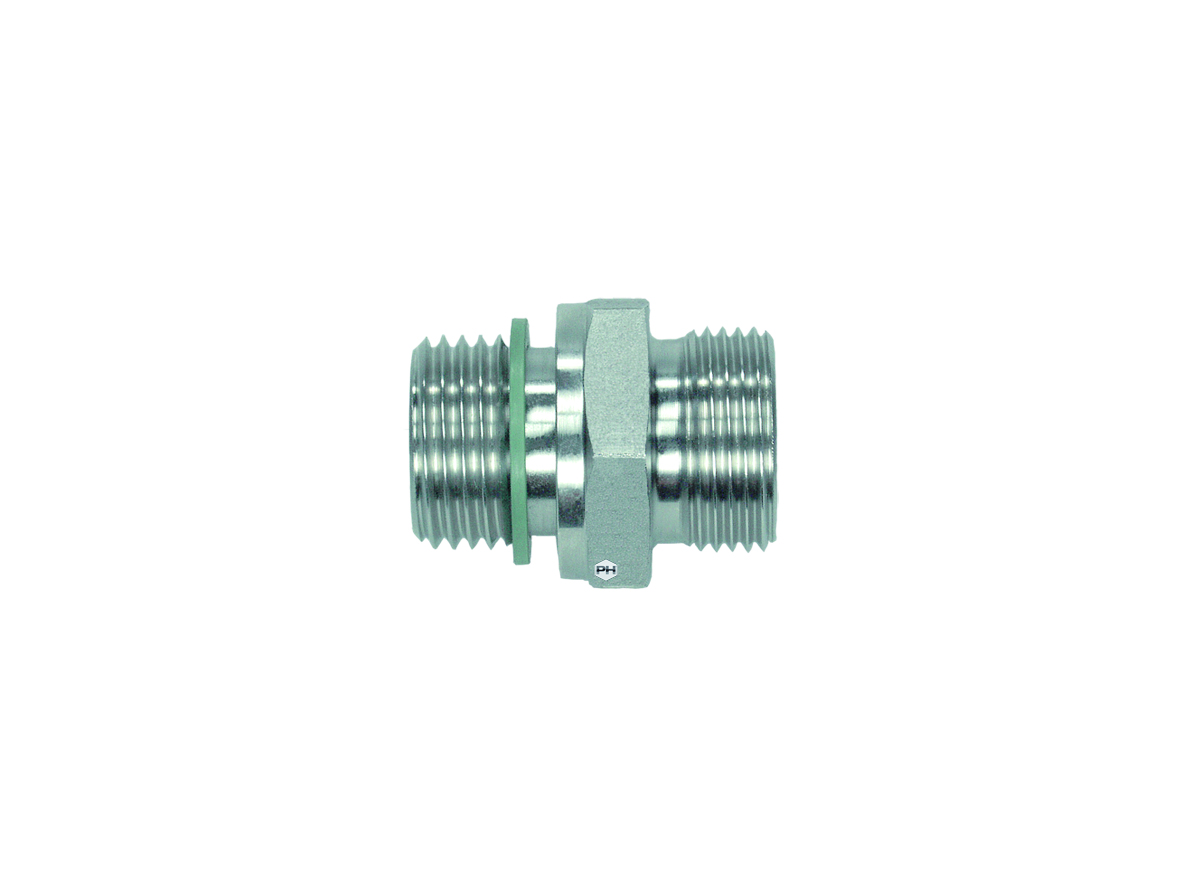

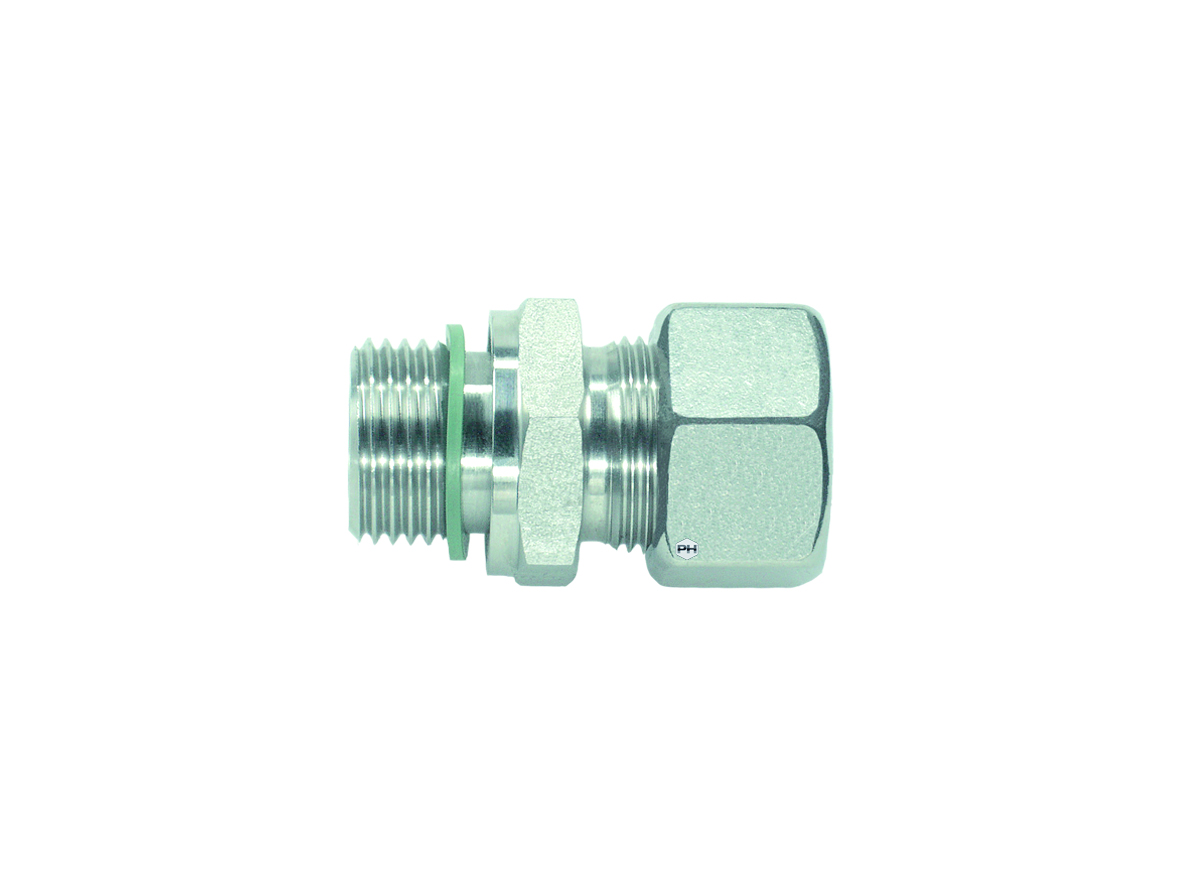

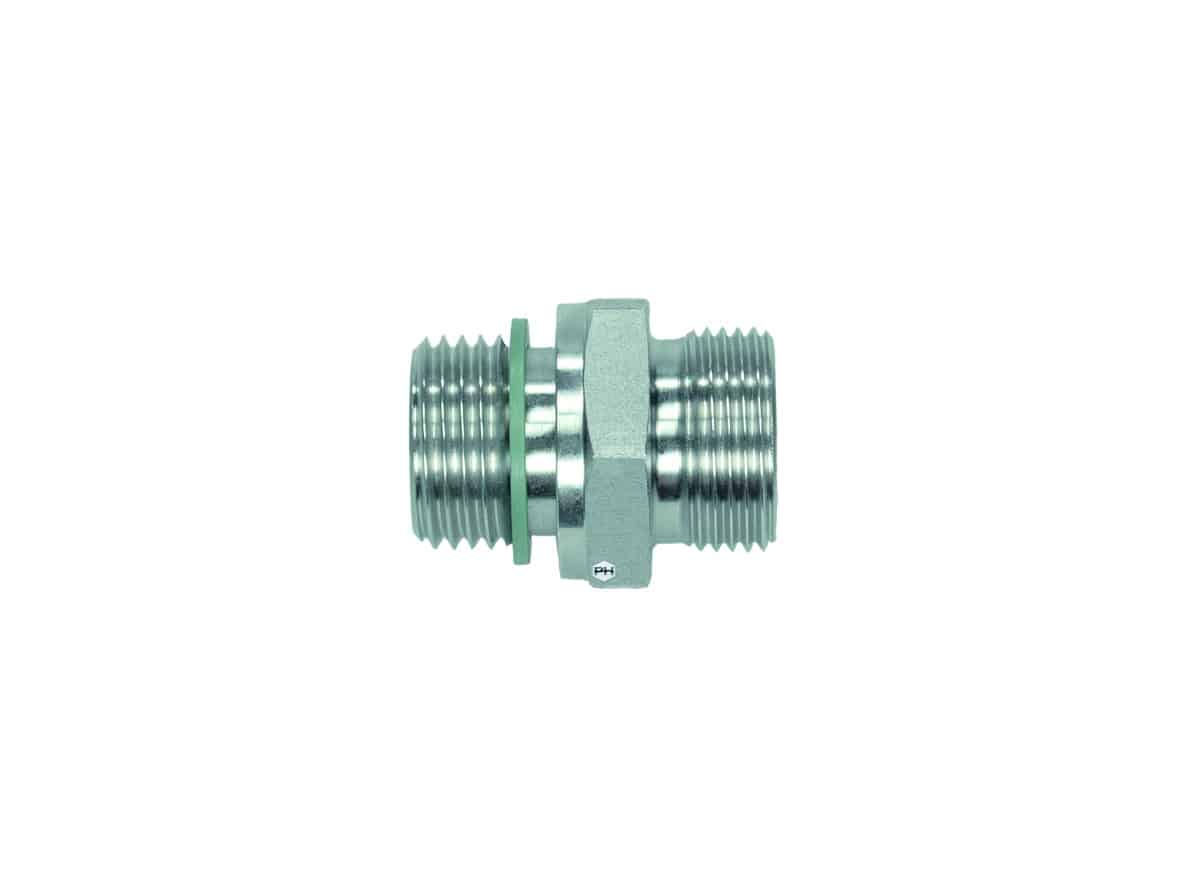

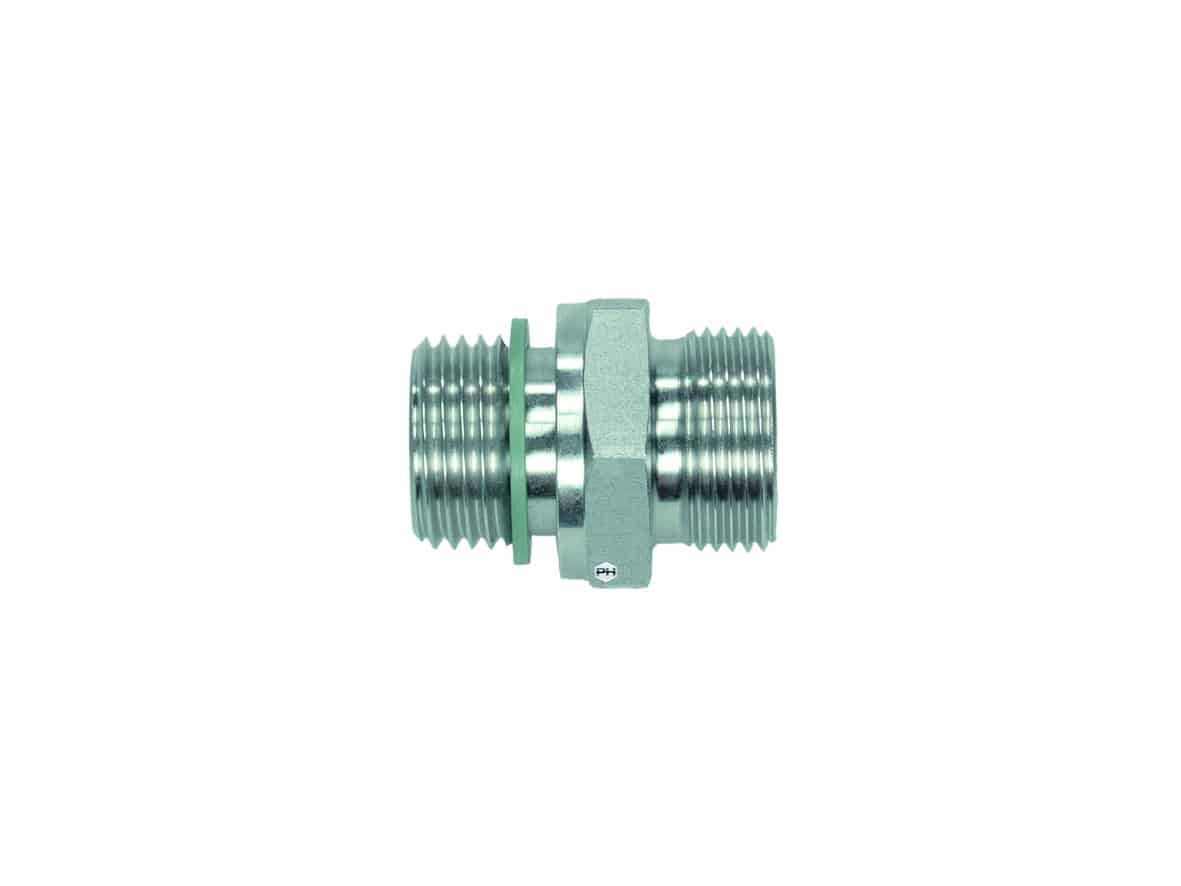

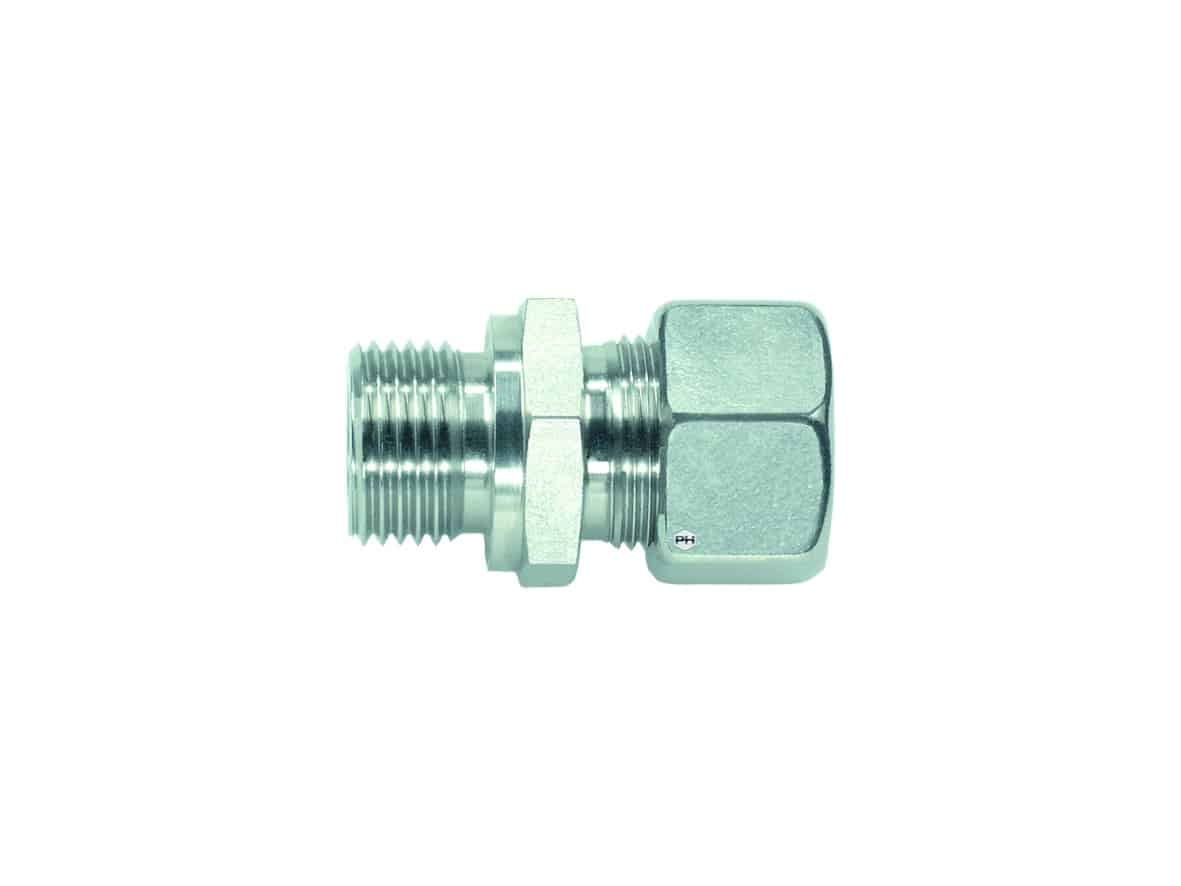

Male stud coupling to BSP parallel – captive seal

-

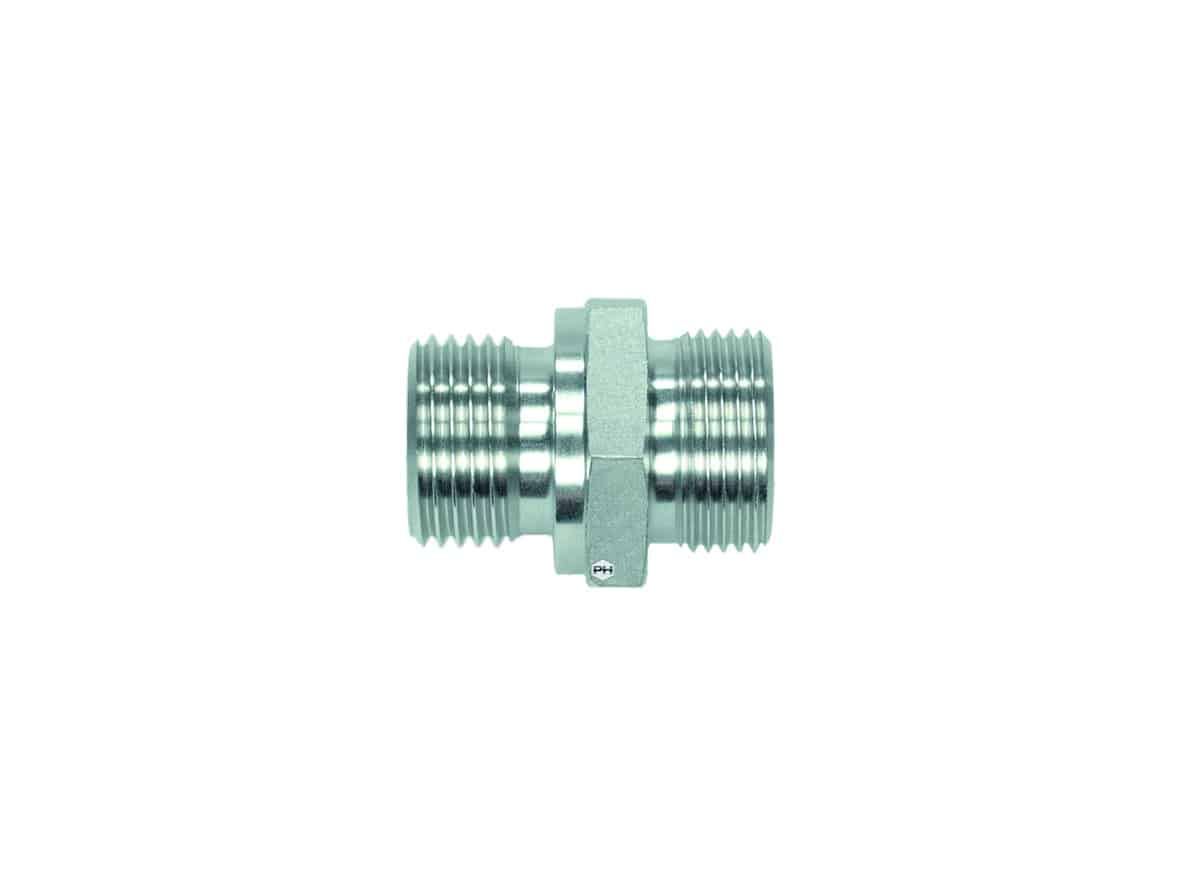

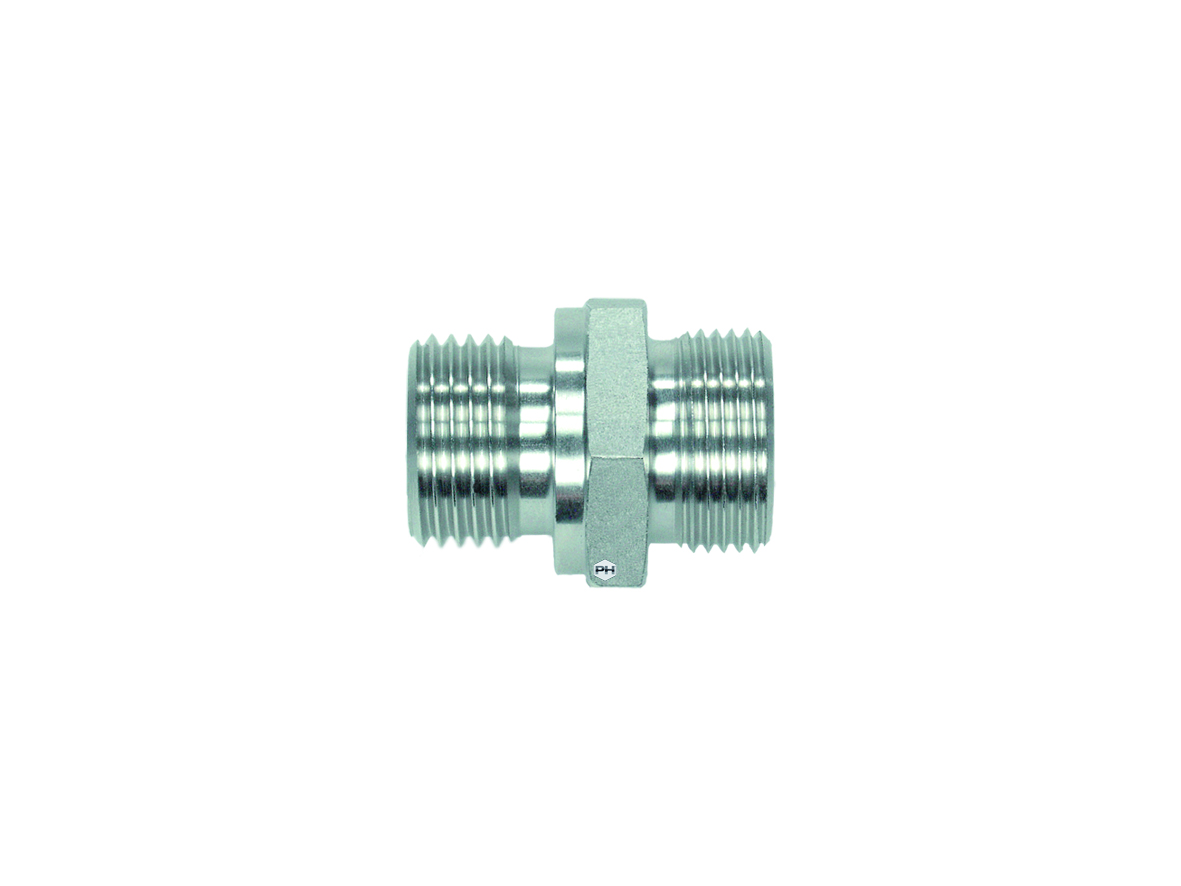

Male stud coupling to BSP parallel

-

Male stud coupling to BSP taper body only

-

Male stud coupling to BSP taper

-

Male stud coupling to metric parallel – captive seal body only

-

Male stud coupling to metric parallel – captive seal

-

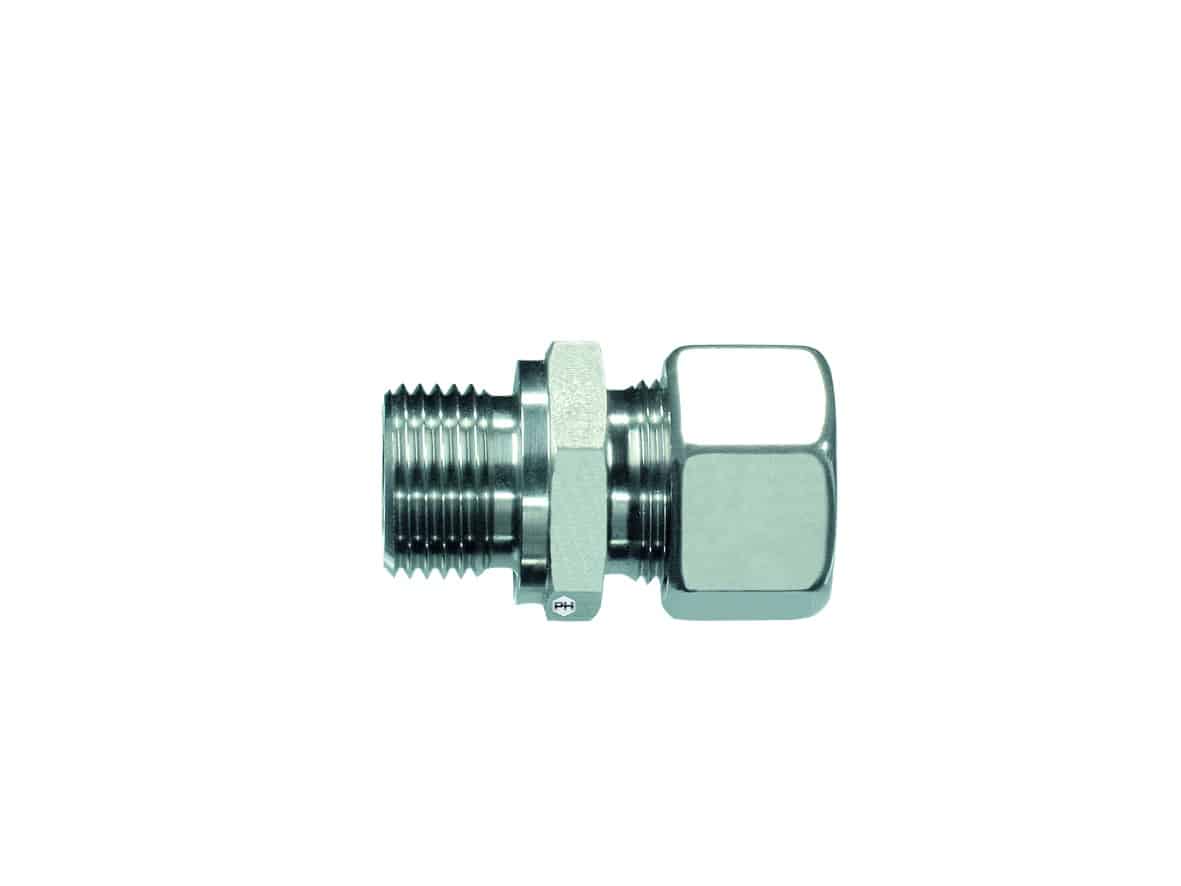

Male stud coupling to metric parallel body only

-

Male stud coupling to metric parallel

-

Male stud coupling to UNF body only

-

Male stud coupling to UNF

-

Male stud coupling to NPT body only

-

Male stud coupling to NPT

-

Male stud coupling to BSP parallel – captive seal - body only

-

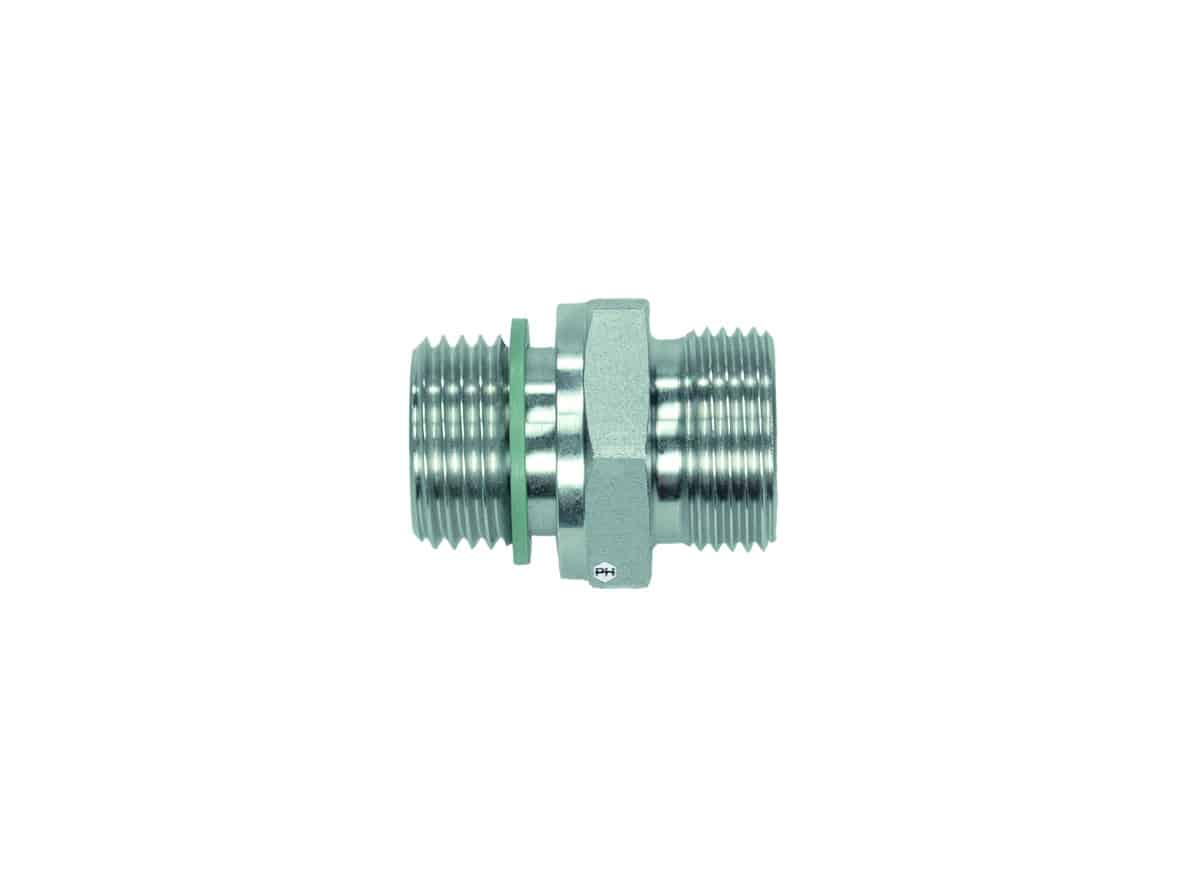

Distance adapter - body only

-

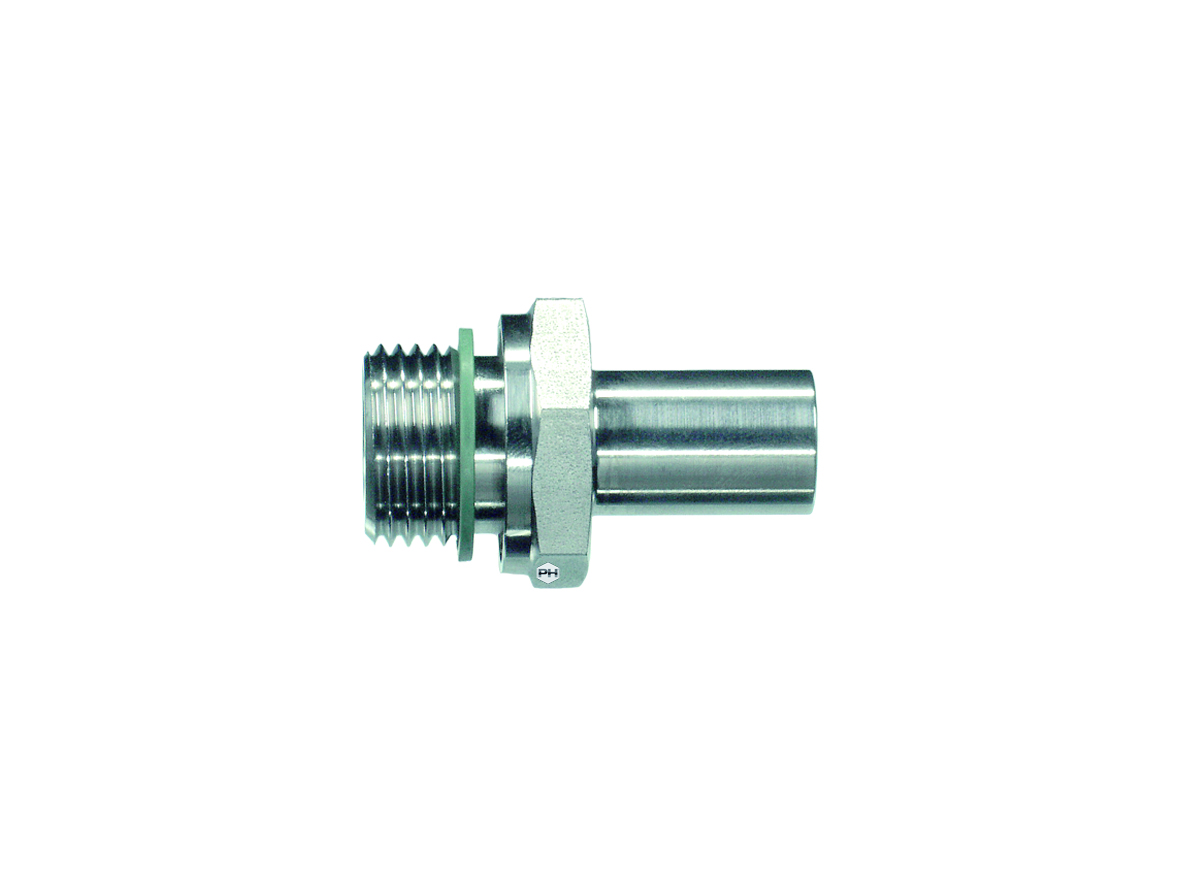

Weld coupling - body only

-

Weld Stub - S Series

-

Weld Stub - S Series - body only

-

Weld Stub - L Series

-

Weld Stub - L Series - body only

-

Male stud coupling to BSP parallel – captive seal

-

Male stud coupling to BSP parallel - body only

-

Male stud coupling to BSP parallel

-

Male stud coupling to BSP taper - body only

-

Male stud coupling to BSP taper

-

Male stud coupling to metric taper - body only

-

Male stud coupling to metric taper

-

Male stud coupling to UNF - body only

-

Male stud coupling to UNF

-

Male stud coupling to metric parallel - body only

-

Male stud coupling to metric parallel – captive seal - body only

-

Male stud coupling to metric parallel – captive seal

-

Male stud coupling to NPT - body only

-

Male stud coupling to NPT

-

Male stud coupling to metric parallel

-

Female stud coupling to NPT - body only

-

Female stud coupling to metric parallel - body only

-

Female stud coupling to metric parallel

-

Female stud coupling to BSP parallel - body only

-

Female stud coupling to BSP parallel

-

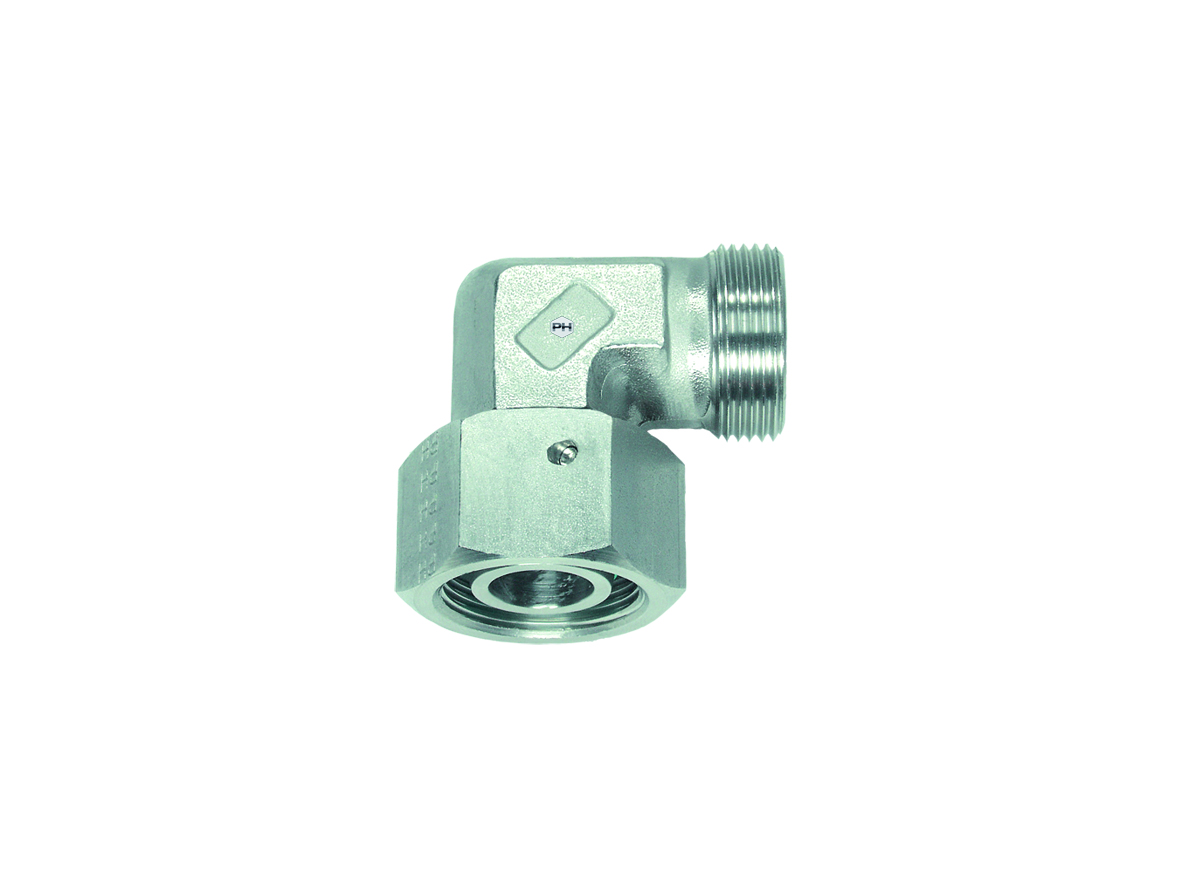

Adjustable female elbow - body only

-

Adjustable female elbow

-

Adjustable standpipe elbow - body only

-

Adjustable standpipe elbow

-

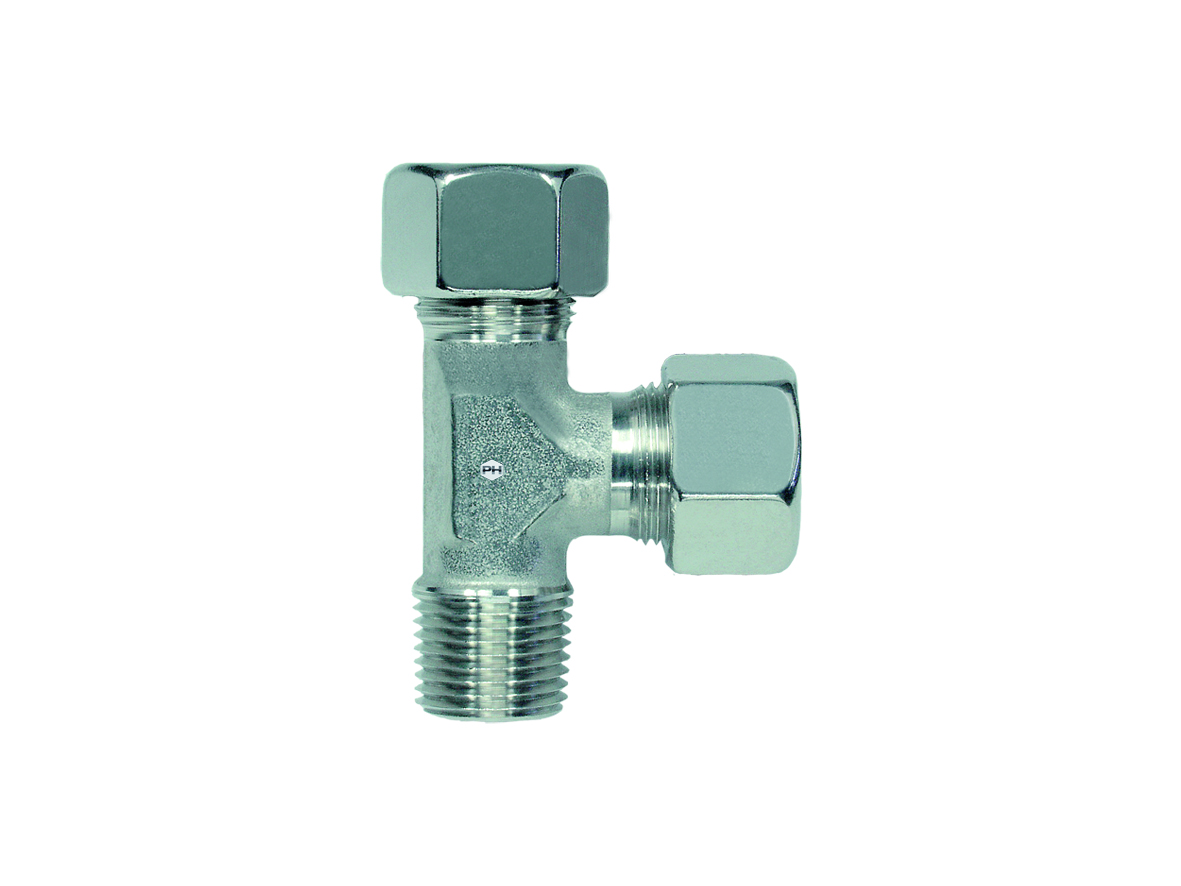

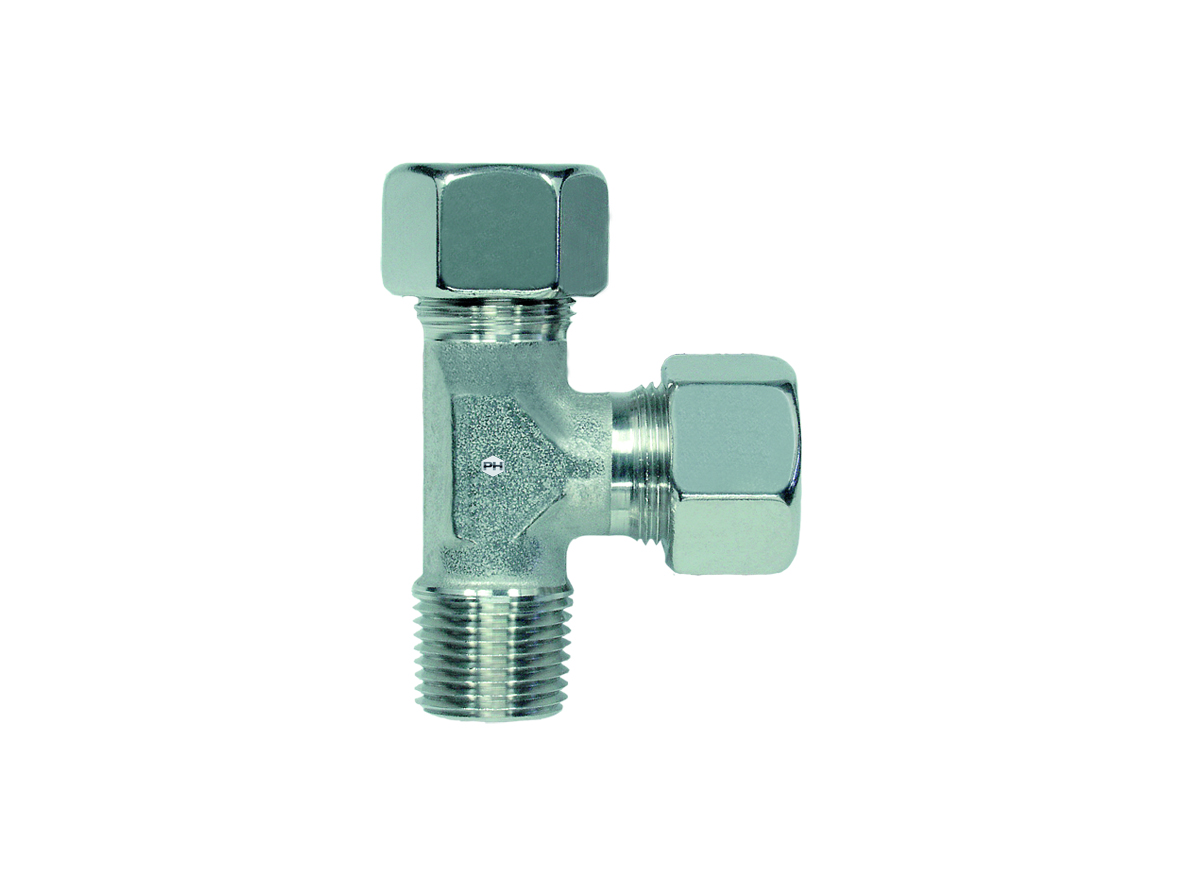

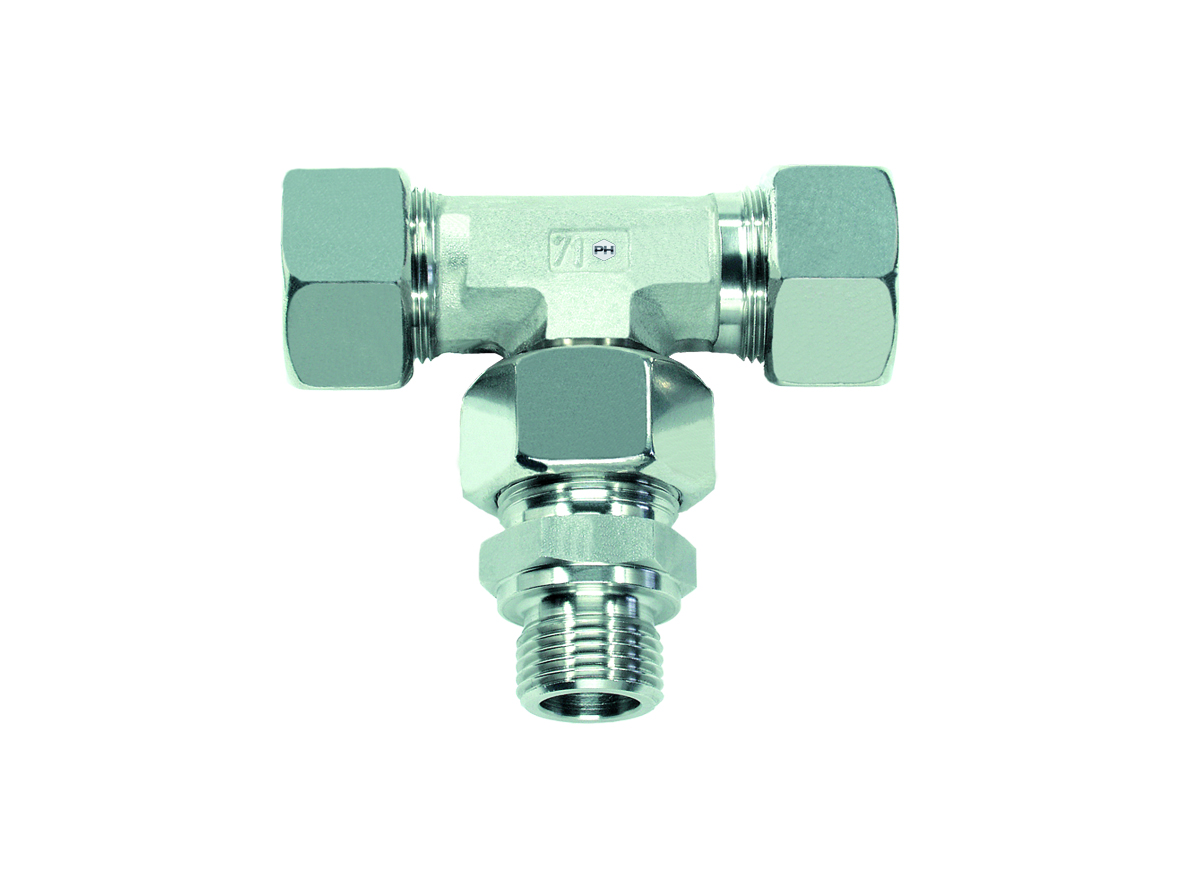

Adjustable standpipe branch tee with BSP parallel male stud

-

Adjustable standpipe branch tee - body only

-

Adjustable standpipe branch tee

-

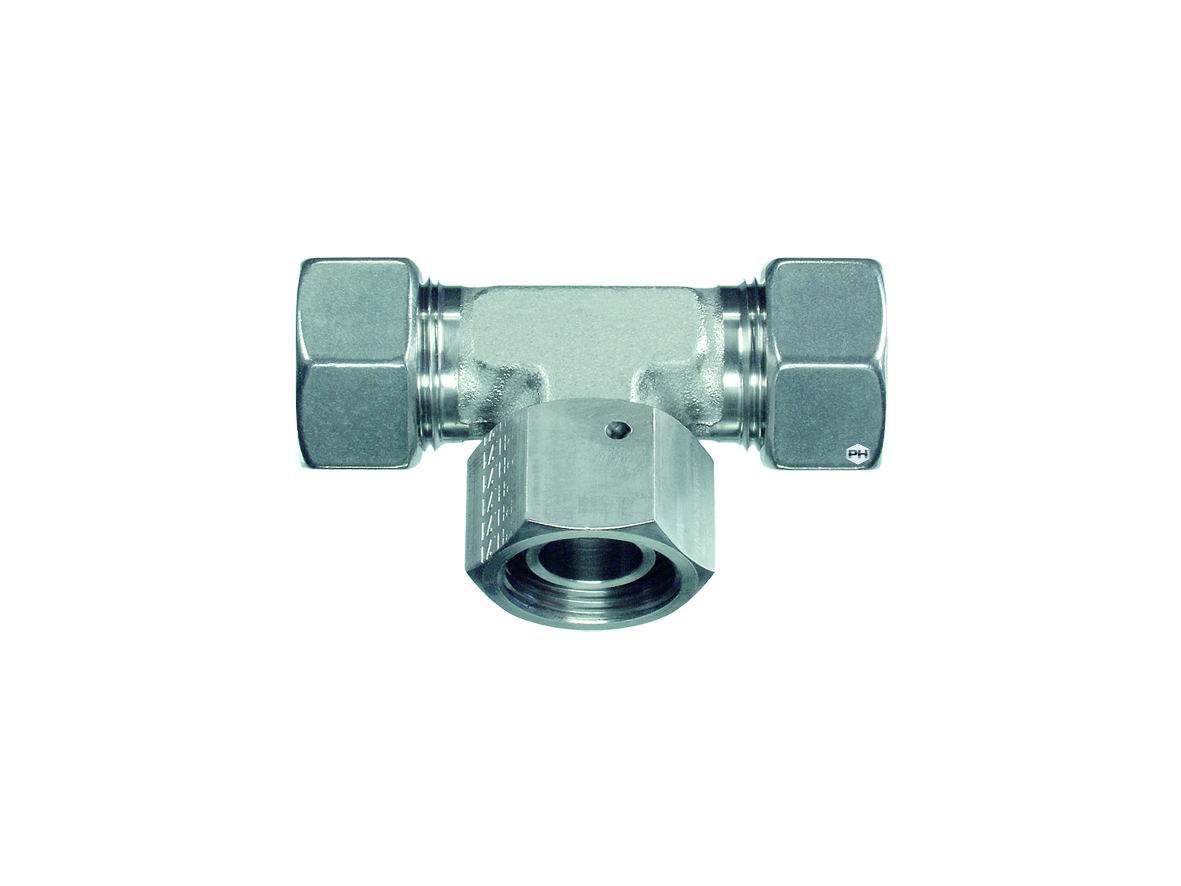

Adjustable standpipe run tee - body only

-

Adjustable standpipe run tee

-

Adjustable standpipe to BSP parallel male

-

Adjustable standpipe to NPT male

-

Standpipe to metric parallel male - body only

-

Standpipe to BSP parallel male - body only

-

Adjustable female 45° elbow - body only

-

Adjustable female 45° elbow

-

Adjustable female branch tee - body only

-

Adjustable female branch tee

-

Bulkhead coupling - body only

-

Bulkhead coupling

-

Double bite compression cutting rings – with Viton soft seal

-

Adjustable female run tee - body only

-

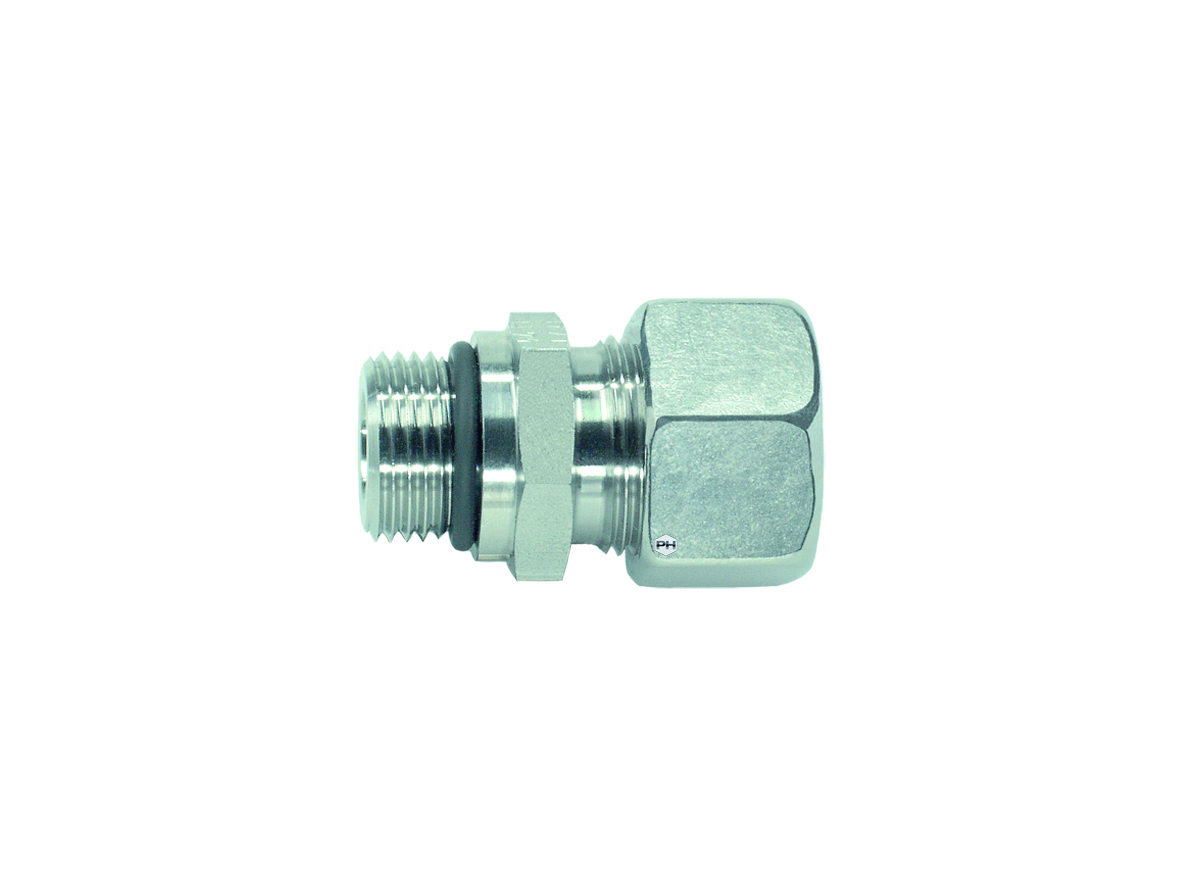

Swivel female to NPT male

-

Swivel female to BSP parallel male

-

Stainless internal sealing rings for pressure gauges

-

Weld coupling

-

Male stud coupling to BSP parallel – captive seal body only

-

Male stud coupling to BSP parallel body only

-

Male stud coupling to BSP parallel

-

Male stud coupling to BSP parallel – captive seal - body only

-

Male stud coupling to BSP parallel - body only

-

Male stud coupling to BSP parallel – captive seal

-

Male stud coupling to BSP parallel

-

Equal elbow

-

Straight coupling

Key Features:

Material: Stainless Steel

Seal Design: Utilises a single ferrule that deforms and bites into the tubing, creating a mechanical seal. Some variations may include an O-ring for enhanced sealing.

Pressure Ratings: Designed to accommodate a broad spectrum of pressure ratings, from low-pressure instrumentation lines to high-pressure hydraulic systems, ensuring suitability for diverse industrial applications.

Advantages:

Easy & Efficient Installation: Requires minimal tools and no specialised skills such as welding, which can significantly reduce the installation time and labour costs.

Reusable & Demountable: Some compression fittings can be easily disassembled and reassembled without compromising the integrity of the seal or damaging components, offering flexibility in system modifications and maintenance.

Versatility: By selecting different fittings to interface with each other they are highly adaptable to various fluid power systems.

Reliable & Leak-Free Connections: Engineered to provide strong, dependable, and leak-resistant connections, even in environments subject to vibration or pressure fluctuations.

Download Catalogue

We’ll email you a PDF version of our catalogue featuring 556 pages of updated engineering reference data. If you want a physical copy, click here